Coanda Screen: Advanced Filtration for Industrial Efficiency

Mutoscreen Ltd., a leading innovator in industrial filtration solutions, presents the Coanda Screen—a cutting-edge product designed to revolutionize filtration processes across various sectors. With its unique design and proven effectiveness, the Coanda Screen addresses critical challenges in industrial applications, offering enhanced performance, cost savings, and sustainability. Discover how this product can transform your operations by visiting Mutoscreen's official product page.

What is the Coanda Screen?

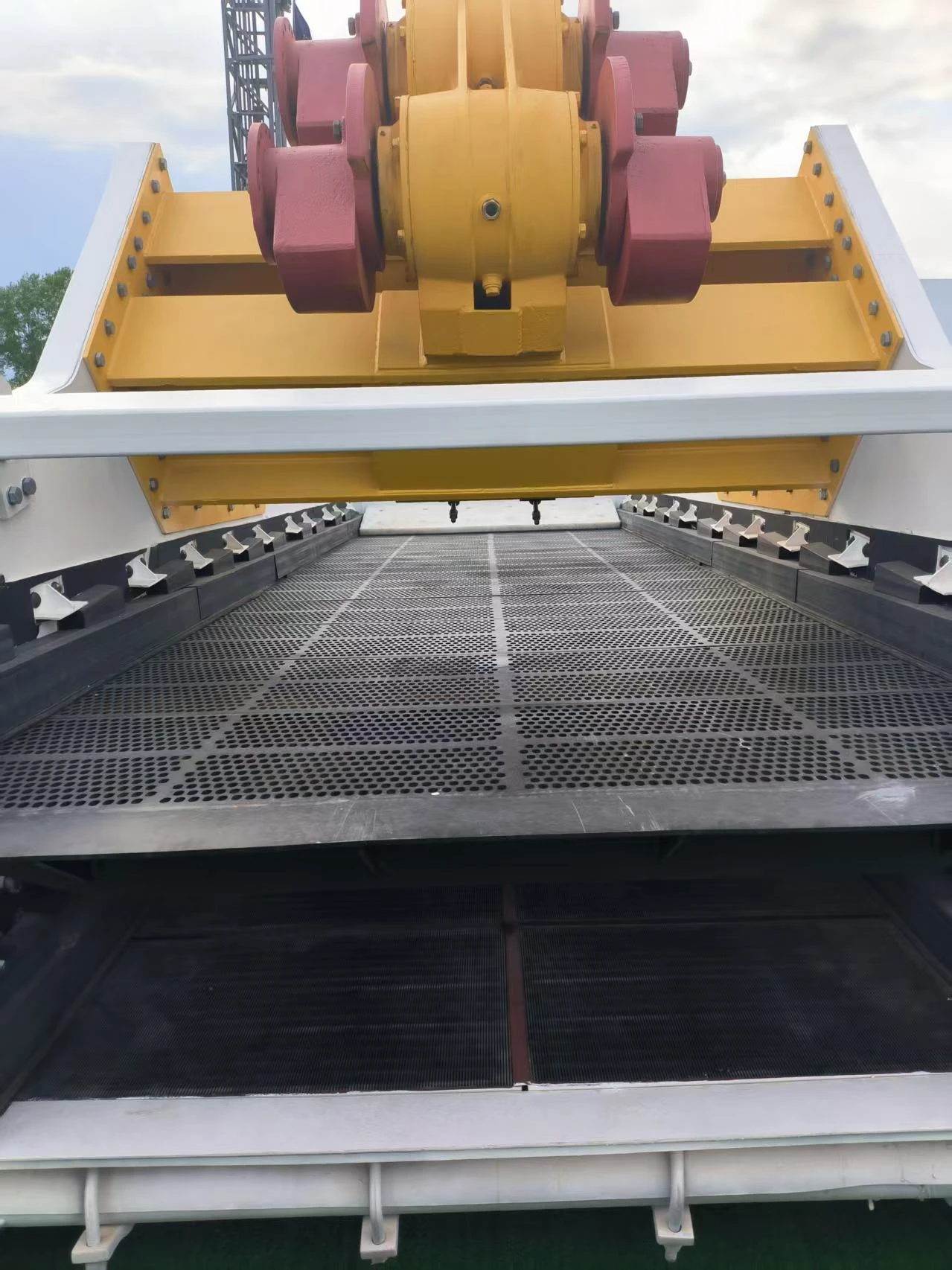

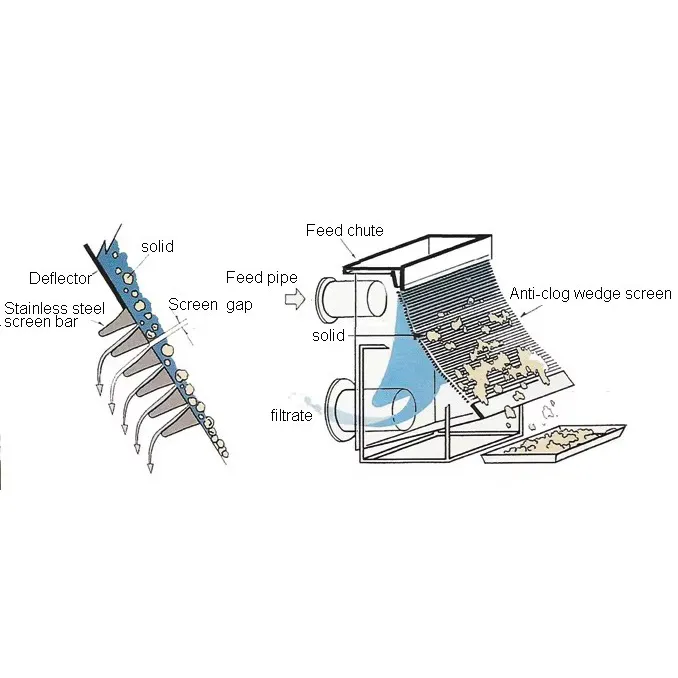

The Coanda Screen is a specialized filtration system that leverages advanced fluid dynamics to optimize particle separation and flow efficiency. Unlike traditional screens, it utilizes the Coanda effect—a phenomenon where a fluid jet adheres to a surface—to enhance filtration accuracy and reduce energy consumption. This technology ensures minimal pressure drop while maintaining high throughput, making it ideal for demanding industrial environments.

Key Benefits for Your Business

- Enhanced Efficiency: The Coanda Screen's design minimizes clogging and maximizes flow rates, reducing downtime and maintenance costs.

- Cost Savings: By improving filtration performance, the product lowers energy consumption and extends the lifespan of downstream equipment.

- Environmental Sustainability: Its energy-efficient operation aligns with global efforts to reduce carbon footprints and promote eco-friendly manufacturing.

- Scalability: The system is adaptable to various industrial applications, from wastewater treatment to food processing and chemical manufacturing.

Addressing Industry Challenges

Traditional filtration systems often struggle with inefficiencies such as frequent clogging, high energy use, and limited adaptability. The Coanda Screen directly tackles these issues by integrating the Coanda effect, which ensures consistent performance even under fluctuating flow conditions. For industries reliant on precise filtration, this innovation translates to reliable operations and reduced operational costs.

Why Choose Mutoscreen Ltd.?

As a pioneer in filtration technology, Mutoscreen Ltd. has built a reputation for delivering high-quality, innovative solutions. With over two decades of expertise, the company combines rigorous R&D with real-world application insights to create products that meet the evolving needs of modern industries. The Coanda Screen is a testament to Mutoscreen's commitment to excellence and sustainability.

Technical Specifications

The Coanda Screen is engineered with precision to meet industrial standards. Key features include:

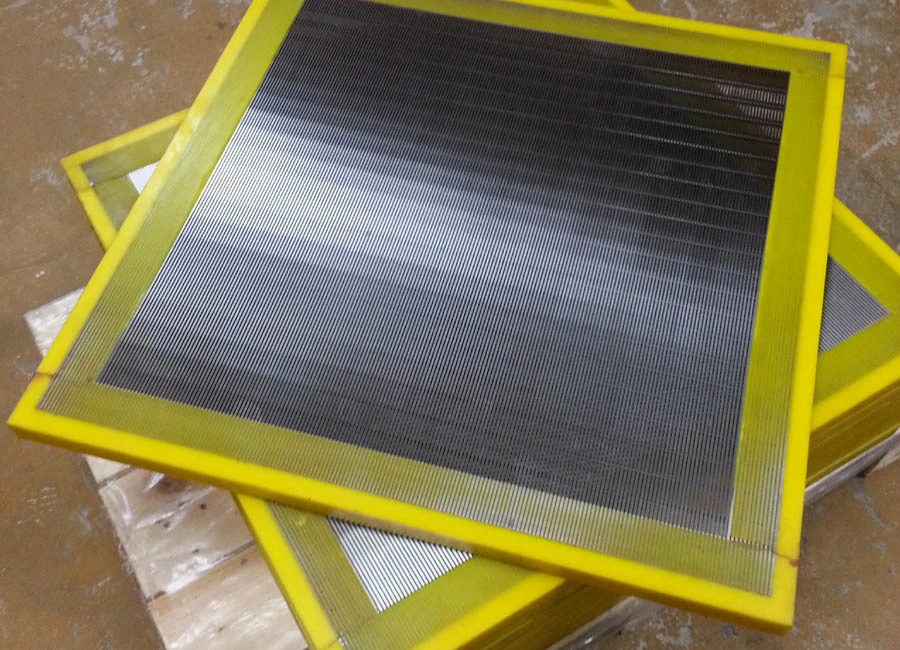

- Material: High-grade stainless steel for durability and corrosion resistance.

- Flow Capacity: Up to 5000 L/min, depending on configuration.

- Particle Removal Efficiency: 98% for particles as small as 10 microns.

- Modular Design: Easy to integrate into existing systems or scale for larger operations.

Applications Across Industries

The Coanda Screen's versatility makes it suitable for a wide range of applications, including:

- Wastewater Treatment: Efficient removal of contaminants to meet regulatory standards.

- Food and Beverage: Ensuring product purity and compliance with hygiene protocols.

- Chemical Processing: Preventing equipment damage from particulate matter.

- Pharmaceuticals: Maintaining sterile conditions during production.

Customer Success Stories

Industry leaders who have adopted the Coanda Screen report significant improvements in operational efficiency. For example, a major food processing plant reduced maintenance costs by 40% within six months of installation. Another client in the chemical sector noted a 30% increase in production output due to the system's reliability.

Implementation and Support

Mutoscreen Ltd. offers comprehensive support to ensure seamless integration of the Coanda Screen into your workflow. This includes:

- Customized Solutions: Tailored designs to match specific operational requirements.

- Technical Consultation: Expert guidance on installation and optimization.

- Ongoing Maintenance: Scheduled checks and prompt repairs to minimize disruptions.

Commitment to Safety and Compliance

The Coanda Screen adheres to international safety and environmental standards, including ISO 9001 and CE certifications. Its design prioritizes user safety, with features such as easy access for cleaning and robust construction to withstand harsh conditions.

How to Get Started

Ready to upgrade your filtration system? Contact Mutoscreen Ltd. today to discuss your needs and receive a personalized quote. Visit our product page to explore technical details or reach out via phone at +44 123 456 7890.

FAQs

Q: Is the Coanda Screen compatible with existing equipment?

A: Yes, its modular design allows for easy integration into most industrial systems.

Q: How often does the Coanda Screen require maintenance?

A: Routine checks every 6-12 months are recommended, depending on usage intensity.

Q: Can the Coanda Screen handle high-viscosity fluids?

A: Yes, it is engineered to maintain efficiency across a wide range of fluid types.

Conclusion

The Coanda Screen by Mutoscreen Ltd. is a game-changer for industries seeking efficient, sustainable filtration solutions. By combining advanced technology with a focus on user needs, it delivers measurable benefits in cost, performance, and environmental impact. Discover how this innovation can elevate your operations—visit Mutoscreen's official page to learn more.