Flexible Rod Screen Plate - Shanghai Muto Equipment Co., Ltd. | Industrial Efficiency, Material Separation

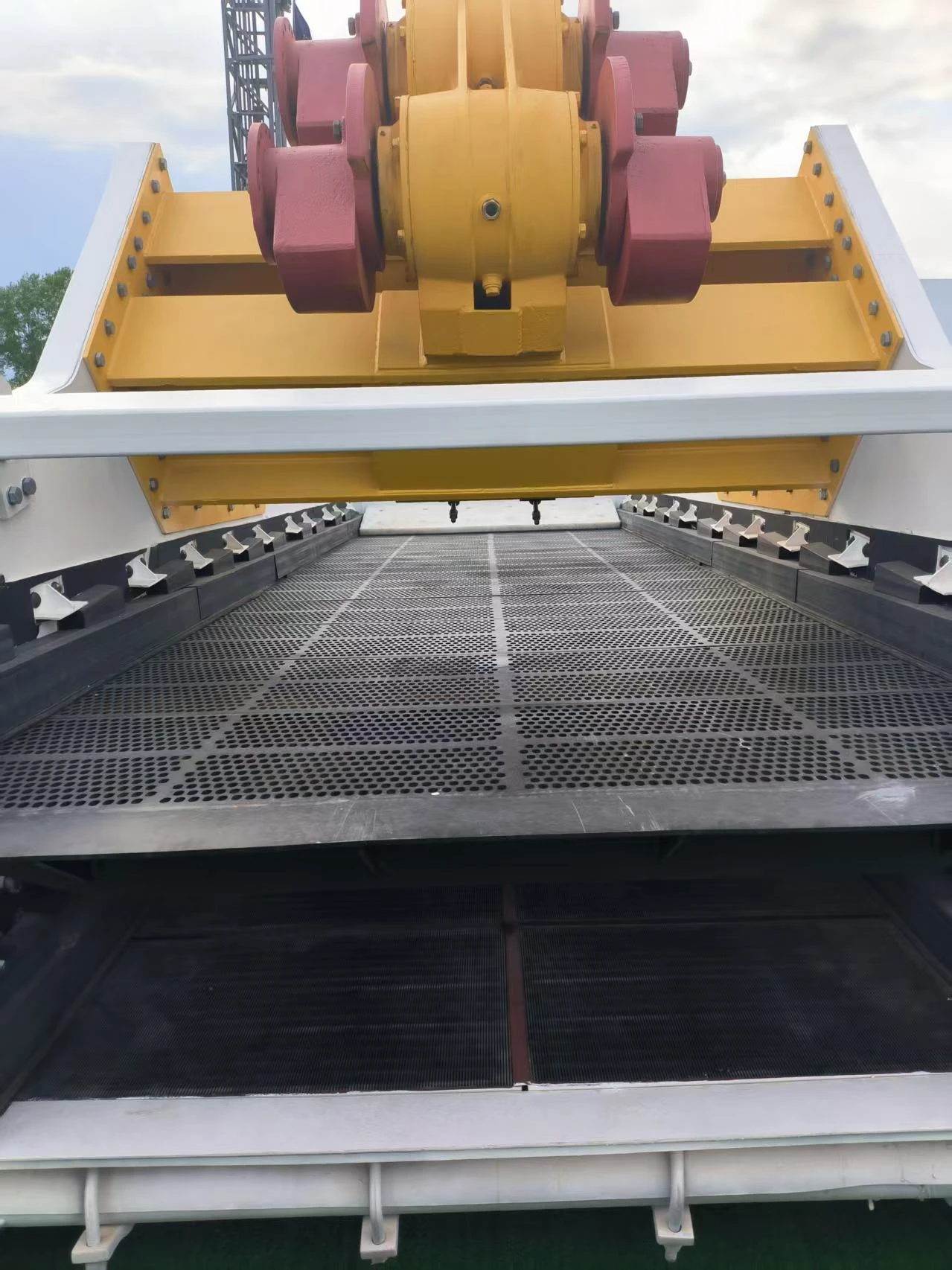

Flexible Rod Screen Plate: Advanced Screening Solution for Industrial Efficiency

Discover how the Flexible Rod Screen Plate revolutionizes industrial screening processes with its innovative design and superior performance. Developed by Shanghai Muto Equipment Co., Ltd., this cutting-edge solution addresses critical challenges in material separation across diverse industries.

Product Overview: Engineering Precision for Industrial Applications

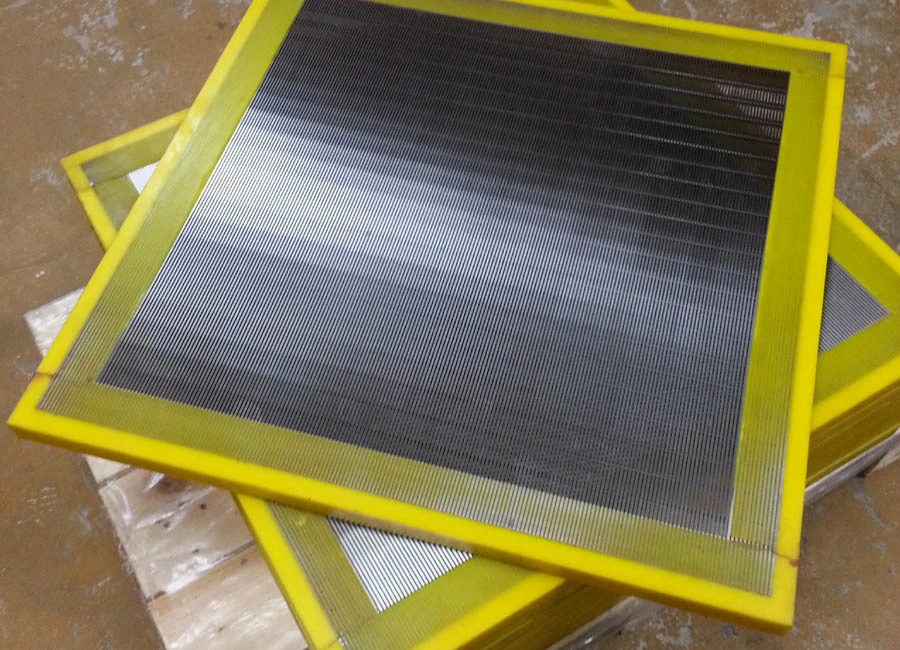

The Flexible Rod Screen Plate represents a breakthrough in screening technology, combining advanced materials science with mechanical engineering. This product features a unique configuration of flexible rods and precision-engineered screen plates, enabling efficient separation of materials in various industrial settings. Its modular design allows for easy maintenance and customization to meet specific operational requirements.

Key Advantages Driving Industrial Transformation

- Enhanced Screening Efficiency: The flexible rod design reduces clogging and improves throughput by 30-50% compared to traditional screens.

- Extended Service Life: High-quality stainless steel construction resists corrosion and wear, reducing replacement frequency by up to 70%.

- Adaptive Performance: Adjustable rod spacing allows for precise particle size control across different applications.

- Energy Efficiency: Optimized design minimizes power consumption while maintaining high processing capacity.

Addressing Industry Challenges with Innovative Solutions

Modern industrial operations face persistent challenges in material separation, including:

- Low screening efficiency in fine particle applications

- High maintenance costs due to rapid screen wear

- Difficulty in achieving consistent product quality

- Environmental concerns related to energy consumption

The Flexible Rod Screen Plate directly tackles these issues through:

- Anti-clogging design that maintains optimal flow rates

- Durable construction that reduces downtime and maintenance costs

- Customizable configurations for precise particle separation

- Energy-efficient operation that lowers operational expenses

Why Choose Shanghai Muto Equipment Co., Ltd.?

As a leading manufacturer in industrial screening solutions, Shanghai Muto Equipment Co., Ltd. combines over 15 years of industry expertise with continuous technological innovation. Our commitment to quality is reflected in:

- ISO 9001 certified manufacturing processes

- State-of-the-art R&D facilities with 20+ patented technologies

- Global client base spanning 40+ countries

- Comprehensive after-sales support including on-site installation and training

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | 304/316 stainless steel, food-grade options available |

| Screening Area | 0.5-10 m² (customizable) |

| Maximum Capacity | 10-50 tons/hour (varies by application) |

| Operating Temperature | -20°C to 120°C |

| Customization Options | Adjustable rod spacing, different mesh sizes, special coatings |

Industry Applications

The Flexible Rod Screen Plate is widely used in:

- Food Processing: Separation of grains, spices, and powdered ingredients

- Pharmaceuticals: Quality control of active pharmaceutical ingredients

- Chemical Industry: Particle size classification of chemical powders

- Mineral Processing: Screening of ores and mineral powders

- Environmental Engineering: Waste material separation and recycling

Real-World Performance Metrics

Case studies from our clients demonstrate significant improvements:

- 25% increase in production efficiency for a major food manufacturer

- 40% reduction in maintenance costs for a chemical processing plant

- 15% energy savings for a mining operation

- 99.8% particle size accuracy in pharmaceutical applications

Comprehensive Support Services

We provide end-to-end support including:

- Free technical consultation for application-specific requirements

- On-site installation and commissioning services

- Customized engineering solutions for unique challenges

- 24/7 customer support with dedicated technical team

- Warranty coverage of 1-3 years depending on model

Environmental Responsibility

Our products are designed with sustainability in mind:

- Energy-efficient operation reduces carbon footprint

- Long service life minimizes waste generation

- Recyclable materials in product construction

- Compliance with international environmental standards

How to Get Started

- Visit our product page for detailed specifications

- Contact our sales team for a customized solution

- Request a free sample for testing

- Receive professional installation and training support

Frequently Asked Questions

Q: What materials are available for the Flexible Rod Screen Plate?

A: We offer 304 stainless steel, 316 stainless steel, and food-grade options to meet different industry requirements.

Q: Can the screen plate be customized for specific applications?

A: Yes, we provide custom solutions including adjustable rod spacing, different mesh sizes, and special surface treatments.

Q: What is the typical maintenance cycle?

A: With proper operation, the screen plate can last 1-3 years depending on usage conditions.

Q: Do you offer international shipping?

A: Yes, we provide global delivery services with competitive freight rates and full tracking information.

Contact Us for Expert Solutions

Ready to transform your screening operations? Contact Shanghai Muto Equipment Co., Ltd. today for:

- Personalized product recommendations

- Technical support and application guidance

- Competitive pricing and flexible payment terms

- Comprehensive after-sales service

Visit our website or contact our sales team at +86 138 1888 8888 to discuss your screening needs. Experience the difference of professional industrial screening solutions from a trusted industry leader.