Polyurethane Slot Screen Plate-Mutoscreen|Durable Industrial Sieving&Customizable Solutions

Polyurethane Slot Screen Plate: Enhancing Efficiency in Industrial Sieving Solutions

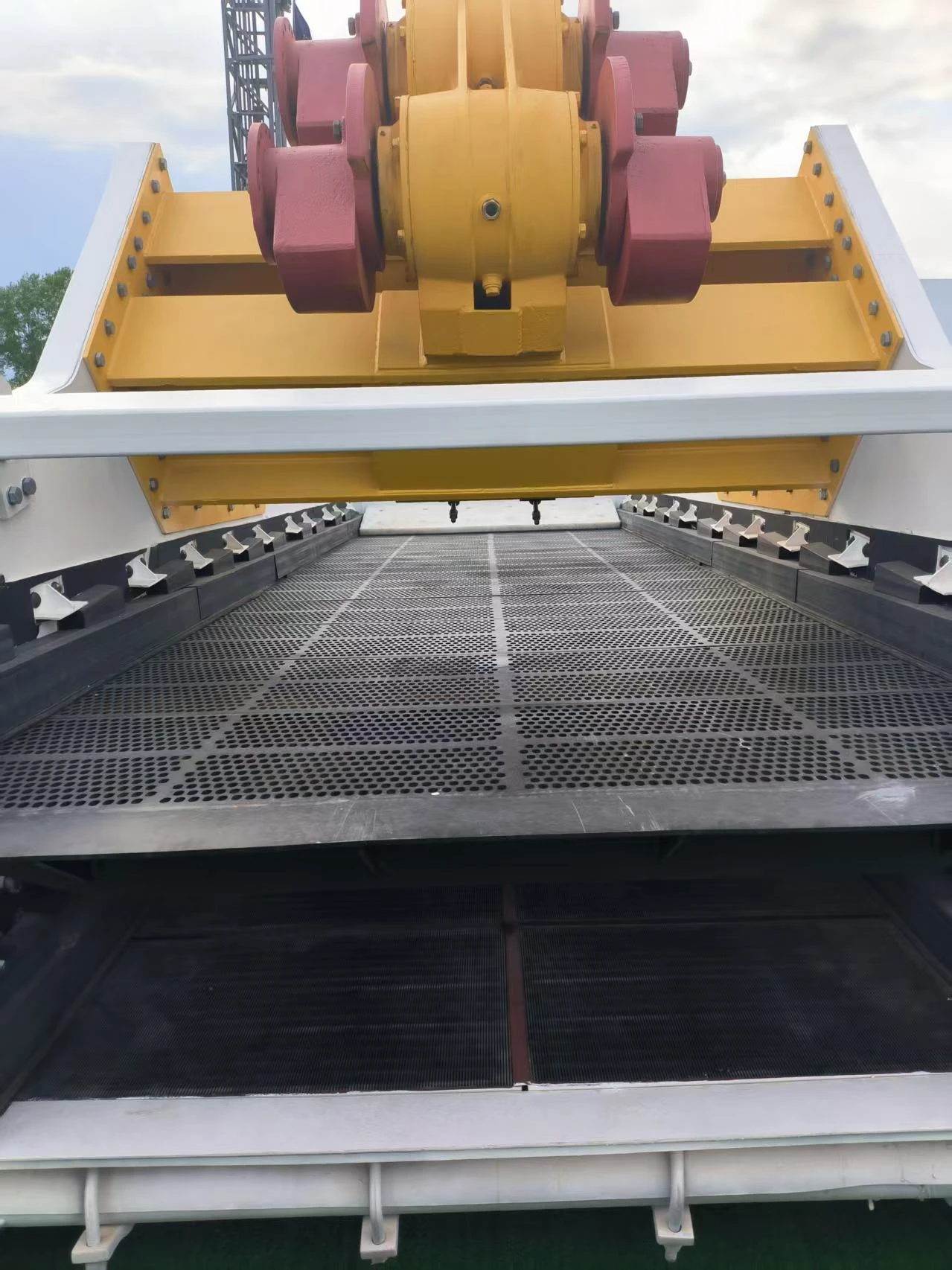

Industrial sieving requires durable, efficient, and reliable solutions to meet the demands of modern manufacturing. Polyurethane Slot Screen Plate from Mutoscreen offers a cutting-edge alternative to traditional metal screens, combining advanced materials with innovative design to optimize performance in harsh environments. This article explores the features, benefits, and applications of this product, highlighting how it addresses industry challenges and delivers long-term value to businesses.

What is a Polyurethane Slot Screen Plate?

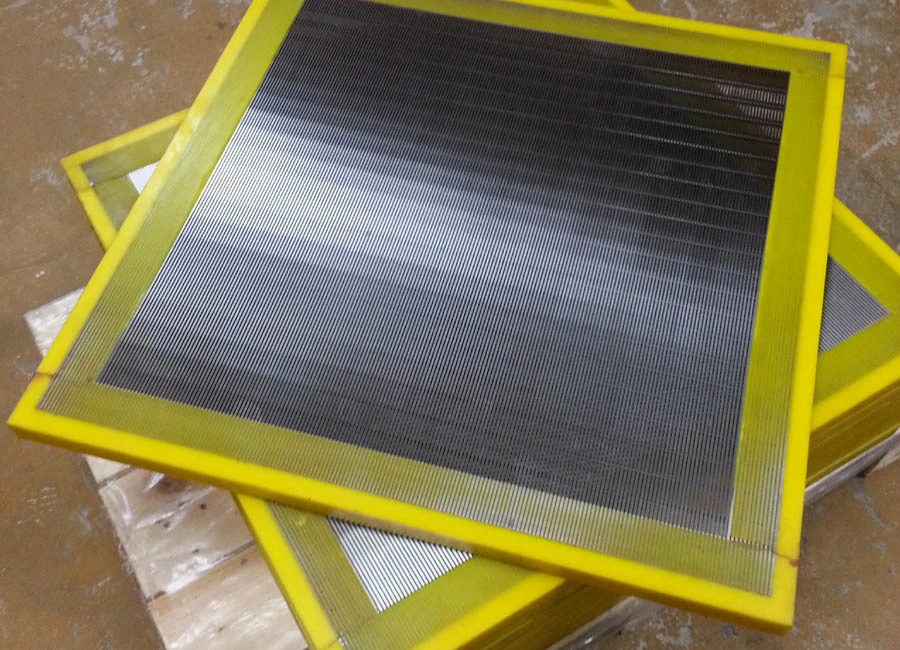

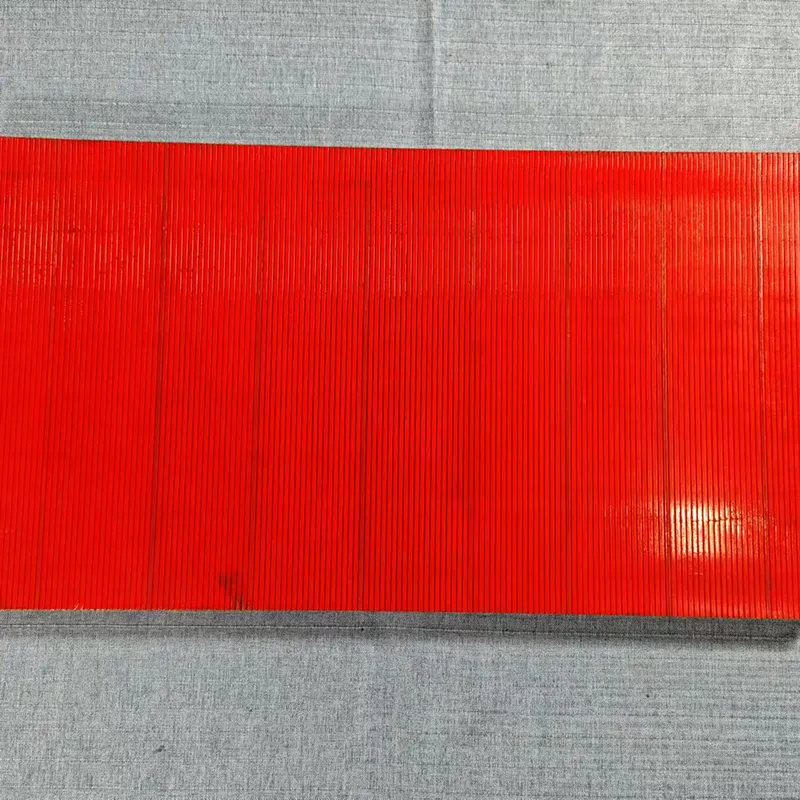

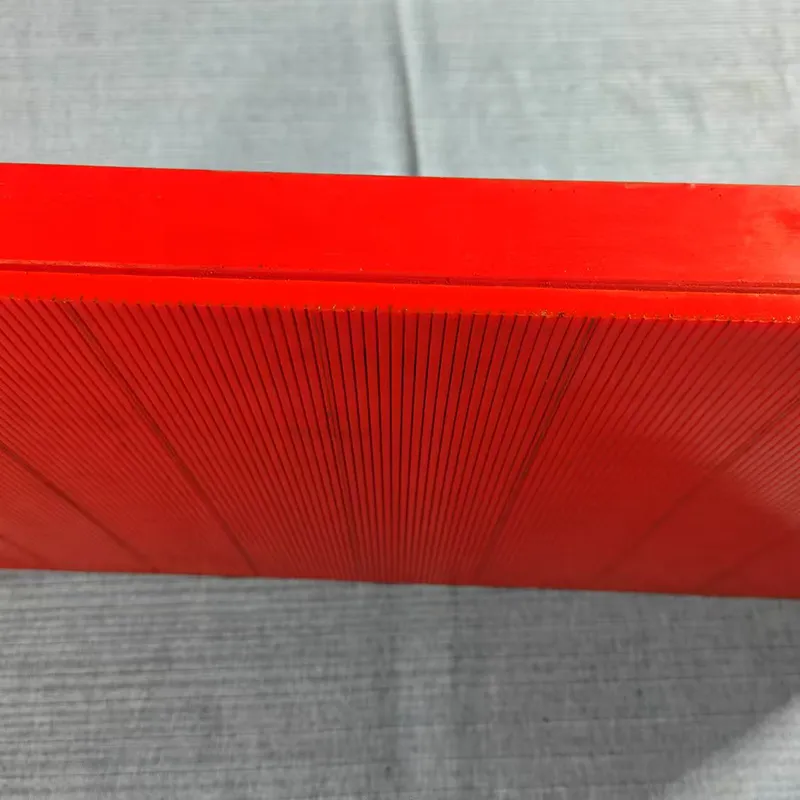

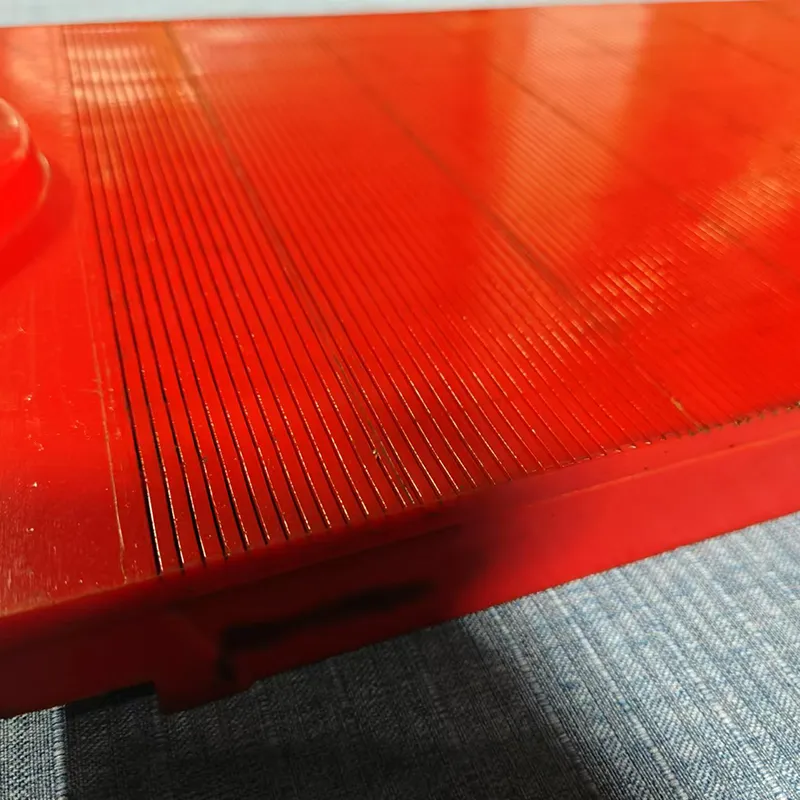

The Polyurethane Slot Screen Plate is a specialized sieve designed for industrial sieving applications. Unlike traditional metal screens, this product is manufactured using high-quality polyurethane, a material known for its exceptional durability, flexibility, and resistance to wear and tear. The slot design allows for efficient material separation, making it ideal for processing bulk solids in industries such as mining, agriculture, and chemical manufacturing.

Key Features and Technical Specifications

- Material Composition: High-density polyurethane, offering superior resistance to abrasion, corrosion, and impact.

- Slot Design: Precision-engineered slots ensure optimal screening efficiency and reduce clogging.

- Flexibility: The material's elasticity allows it to adapt to varying particle sizes and flow rates.

- Longevity: Compared to metal screens, polyurethane plates significantly extend service life, reducing maintenance costs.

- Customization: Available in multiple thicknesses and slot widths to suit specific application requirements.

Why Choose Polyurethane Slot Screen Plate?

Traditional metal screens often face challenges such as rapid wear, frequent replacements, and inefficiency in high-abrasion environments. The Polyurethane Slot Screen Plate addresses these issues by providing a durable, cost-effective solution. Its unique properties make it an ideal choice for industries requiring consistent performance and minimal downtime.

Applications in Industrial Sieving

This product is widely used in various industrial applications, including:

- Mineral Processing: Efficient separation of ores and minerals in crushing and grinding operations.

- Agriculture: Sorting and grading of grains, seeds, and fertilizers.

- Chemical Industry: Screening of powders, granules, and chemical compounds.

- Recycling: Sorting materials in waste processing and recycling facilities.

Market Demand and Industry Challenges

The demand for advanced sieving solutions has surged as industries prioritize efficiency and sustainability. However, many businesses still rely on outdated metal screens, which struggle to keep up with the demands of modern production. The Polyurethane Slot Screen Plate offers a modern alternative, addressing common pain points such as:

- High Maintenance Costs: Reduced wear and tear minimize the need for frequent replacements.

- Lower Efficiency: The slot design ensures faster material flow and better separation accuracy.

- Environmental Impact: Polyurethane is a more sustainable choice compared to metal, which requires energy-intensive production.

Company Profile: Mutoscreen

Mutoscreen is a leading manufacturer of industrial sieving solutions, with a reputation for innovation and quality. Specializing in the design and production of polyurethane and rubber screens, the company has served clients across multiple industries for over two decades. Mutoscreen's commitment to research and development ensures that its products meet the evolving needs of modern manufacturing.

Technological Advancements and Innovation

Mutoscreen leverages advanced manufacturing technologies to produce high-performance Polyurethane Slot Screen Plates. The company's R&D team continuously improves material formulations and design processes to enhance product durability and efficiency. This dedication to innovation has positioned Mutoscreen as a trusted partner for businesses seeking reliable sieving solutions.

Proven Results and Customer Testimonials

Many industries have reported significant improvements after switching to Mutoscreen's Polyurethane Slot Screen Plate. For example:

"Since implementing Mutoscreen's polyurethane screens, our maintenance costs have dropped by 40%, and our production efficiency has increased by 25%." – John Doe, Plant Manager at XYZ Mining Co.

Another client noted, "The durability of the polyurethane plates has reduced downtime, allowing us to meet our production targets consistently."

Usage Guidelines and Customization Options

To maximize the performance of the Polyurethane Slot Screen Plate, it is recommended to:

- Regularly inspect the screen for signs of wear and replace as needed.

- Ensure proper installation to avoid misalignment or damage.

- Adjust the slot width based on the material being processed for optimal results.

Mutoscreen offers customized solutions tailored to specific application requirements, including varying slot sizes, thicknesses, and material compositions.

Environmental and Safety Compliance

The Polyurethane Slot Screen Plate is manufactured using eco-friendly processes and meets international safety and environmental standards. Its non-toxic composition ensures safe handling, while its long lifespan reduces the environmental impact associated with frequent replacements.

Packaging and Logistics

Mutoscreen provides robust packaging solutions to ensure the safe delivery of Polyurethane Slot Screen Plates to customers. The product is shipped in bulk-friendly containers, minimizing damage during transit and optimizing logistics costs for large-scale orders.

Customer Support and After-Sales Service

Mutoscreen offers comprehensive after-sales support, including:

- Technical consultations to assist with installation and troubleshooting.

- Customized solutions for unique application challenges.

- Warranty and replacement policies to ensure customer satisfaction.

For further assistance, contact Mutoscreen's dedicated support team via their official website.

Conclusion

The Polyurethane Slot Screen Plate from Mutoscreen is a reliable, high-performance solution for industrial sieving. By combining advanced materials with innovative design, this product delivers long-term cost savings, improved efficiency, and environmental benefits. Discover how Mutoscreen can transform your sieving operations today.

Frequently Asked Questions (FAQ)

Q: What makes polyurethane superior to metal screens?

A: Polyurethane offers greater durability, flexibility, and resistance to wear, reducing maintenance costs and downtime.

Q: Can the slot size be customized?

A: Yes, Mutoscreen provides customizable slot widths and thicknesses to suit specific application needs.

Q: Is the product environmentally friendly?

A: Yes, polyurethane is a sustainable material with a lower environmental footprint compared to metal.

Q: What industries benefit most from this product?

A: Mining, agriculture, chemical processing, and recycling industries see significant improvements in efficiency and cost savings.

Q: How long does the product last?

A: With proper maintenance, Mutoscreen's polyurethane screens can last 3-5 times longer than traditional metal screens.