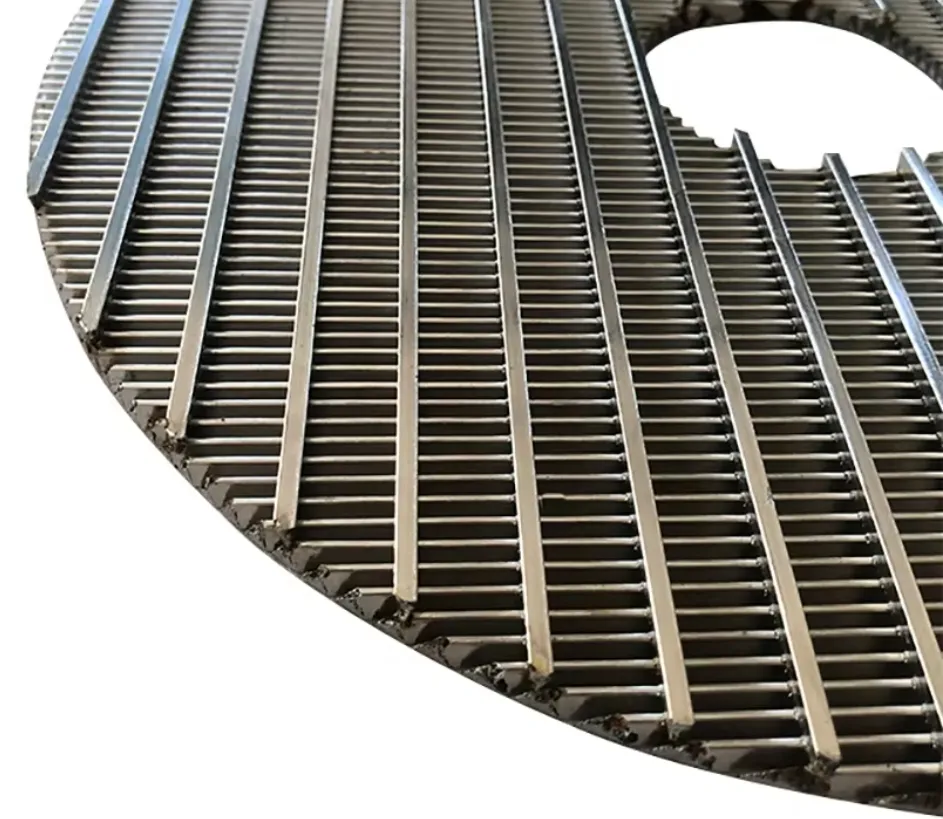

Wedge wire mesh has emerged as a cornerstone of industrial filtration, offering unparalleled precision and durability. Characterized by its V-shaped wires welded onto support rods, this innovative design ensures consistent slot openings that resist clogging while maintaining high flow rates. Industries ranging from oil and gas to food processing rely on wedge wire mesh for its ability to handle abrasive materials, extreme temperatures, and corrosive environments. Its modular construction allows for easy installation and maintenance, reducing downtime in critical operations.

At our manufacturing facilities, wedge wire mesh is crafted using premium stainless steel or specialized alloys, tailored to withstand the unique challenges of each application. Whether separating solids in mining operations or filtering wastewater in municipal plants, our products deliver unmatched longevity. With exports to over 40 countries, we’ve refined our designs to meet global standards, ensuring compatibility with regional regulations and operational demands. Clients in Asia, Europe, and beyond trust our wedge wire mesh for its adaptability, whether deployed in vertical sieve bends or cylindrical filter cartridges.

Customized Wedge Wire Screen Panels for Diverse Applications

Wedge wire screen panels are engineered to address the specific needs of industries worldwide. Unlike generic screens, our panels are custom-designed to match exact particle retention requirements, flow rates, and mechanical stresses. For instance, in the agricultural sector, wedge wire screen panels are optimized for grain sorting, ensuring minimal breakage and maximum efficiency. In contrast, mining operations demand panels with reinforced edges to endure heavy impact loads during mineral extraction.

Our global clientele benefits from a collaborative design process. By analyzing operational parameters such as feed composition and pressure conditions, we develop wedge wire screen panels that outperform off-the-shelf alternatives. A recent project for a European chemical plant involved creating panels with ultra-fine slots to capture micron-sized impurities, significantly extending the lifespan of downstream equipment. This bespoke approach has solidified our reputation as a leader in filtration solutions across six continents.

Choosing the Right Wedge Wire Screen Sizes for Optimal Performance

Selecting appropriate wedge wire screen sizes is critical to achieving peak filtration efficiency. Screen slot widths, which typically range from 20 microns to 25 millimeters, determine the size of particles retained. For example, in water treatment plants, narrower slots are used to remove fine sediments, while broader openings in oil drilling screens allow rapid separation of coarse debris. Our technical team assists clients in balancing throughput and precision, ensuring screens neither clog prematurely nor let contaminants slip through.

Material thickness and wire spacing also influence wedge wire screen sizes. Thicker wires enhance structural integrity for high-pressure environments, whereas tighter spacing improves filtration accuracy. A North American client in the pulp and paper industry recently upgraded to larger-panel wedge wire screen sizes to accommodate increased production volumes, reducing maintenance intervals by 30%. By aligning screen dimensions with operational goals, we help businesses optimize their processes sustainably.

V Wire Screen: Enhancing Durability and Efficiency

The V wire screen, a variant of wedge wire technology, features a distinctive profile that combines strength with precision. Its V-shaped wires create a smooth surface that minimizes friction, ideal for applications involving sticky or fibrous materials. In the aquaculture industry, V wire screens are used to filter algae from water supplies without damaging delicate marine ecosystems. Similarly, sugar refineries employ these screens to separate crystals from molasses, ensuring high-purity outputs.

Durability is a hallmark of V wire screens. The continuous weld between wires and support rods eliminates weak points, making them resistant to deformation under heavy loads. A case study in Africa demonstrated how V wire screens in a desalination plant withstood prolonged exposure to saltwater, outperforming traditional mesh by over five years. This resilience, paired with low maintenance needs, makes V wire screens a cost-effective choice for industries prioritizing long-term reliability.

Wedge Wire Mesh FAQs

What Makes Wedge Wire Mesh Ideal for Home Water Filtration Systems?

Wedge wire mesh is perfect for residential use due to its self-cleaning design. The uniform slots prevent debris buildup, ensuring consistent water flow without frequent manual cleaning. Its corrosion-resistant materials also guarantee safety for drinking water.

How Do Wedge Wire Screen Panels Improve Agricultural Irrigation?

Wedge wire screen panels filter out sand and organic matter from irrigation water, protecting drip systems from blockages. Their robust construction withstands outdoor conditions, reducing replacement costs for farmers.

Can V Wire Screens Be Used in DIY Projects?

Absolutely! V wire screens are popular among DIY enthusiasts for creating garden sieves or compost sifters. Their lightweight yet sturdy build allows for easy customization using basic tools.

Are Wedge Wire Screen Sizes Adjustable for Small-Scale Applications?

Yes, we offer wedge wire screen sizes tailored to small operations, such as boutique breweries or aquariums. Custom sizing ensures even compact systems achieve professional-grade filtration.

What Maintenance Is Required for Wedge Wire Mesh in Residential Pools?

Routine rinsing with a hose is usually sufficient to keep wedge wire mesh clean in pools. Avoid harsh chemicals to preserve the screen’s anti-corrosion properties.

For over a decade, we’ve supplied wedge wire mesh, wedge wire screen panels, and V wire screens to industries worldwide. Our commitment to customization and quality ensures your filtration challenges are met with innovative solutions. Visit our website to explore our catalog or contact our team for a tailored quote. Transform your processes with screens engineered for excellence—wherever your operations are.