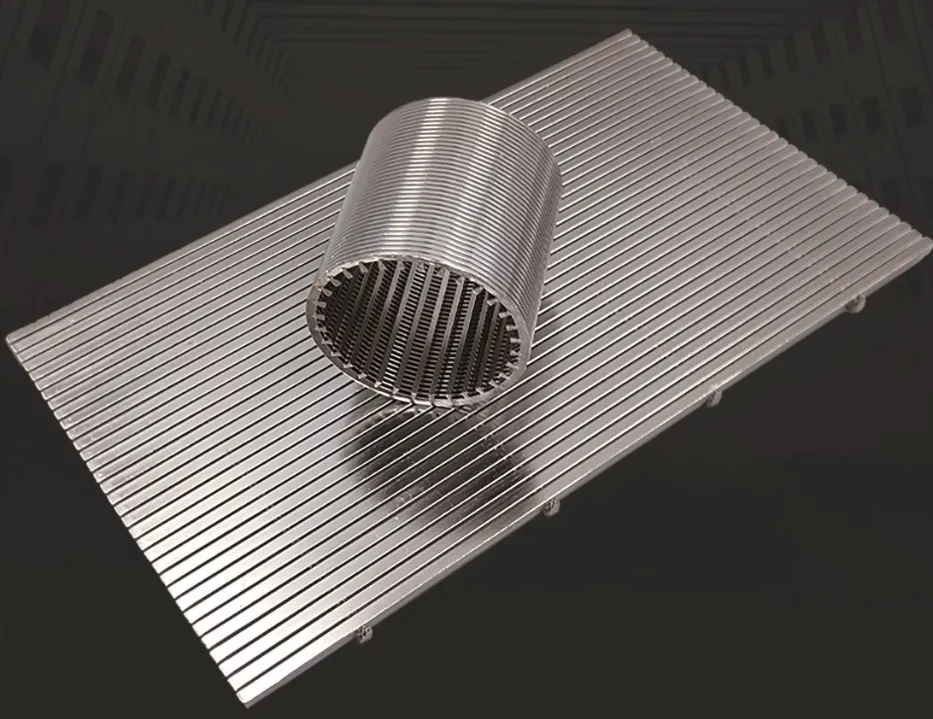

In the demanding world of chemical processing, materials must withstand aggressive substances, extreme temperatures, and corrosive conditions. Vee wire screens, engineered with precision and resilience, have emerged as a critical component in these environments. Their unique design, characterized by V-shaped wires welded onto support rods, creates a robust filtration surface that resists chemical degradation. Unlike traditional screens, which may warp or corrode under prolonged exposure to acids, alkalis, or solvents, stainless steel well screens maintain structural integrity, ensuring uninterrupted operations.

The secret to their exceptional chemical resistance lies in the material composition. High-grade stainless steel alloys, such as 304, 316, or 316L, are commonly used in wedge wire screens, offering inherent resistance to oxidation and pitting. This makes them ideal for applications like acid filtration, solvent recovery, or wastewater treatment, where exposure to aggressive media is unavoidable. For instance, in pharmaceutical manufacturing, vee wire screens are employed to filter reactive intermediates, ensuring purity while avoiding contamination risks. Their longevity reduces downtime for replacements, translating to cost savings for industries reliant on continuous production cycles.

Moreover, well screens suppliers emphasize customization to address specific chemical challenges. By adjusting wire thickness, slot sizes, or alloy grades, screens can be tailored to resist localized corrosion or high-pressure conditions. This adaptability ensures that industries—from petrochemical plants to food processing facilities—receive solutions optimized for their unique operational demands.

Long Lifespan: How Vee Wire Screens Outperform Traditional Filtration Systems

The longevity of vee wire screens is a game-changer for industries seeking sustainable and low-maintenance filtration options. Traditional mesh screens or perforated plates often fail prematurely due to clogging, abrasion, or chemical attack, leading to frequent replacements and operational disruptions. In contrast, the open-area design of wedge wire screens minimizes particle buildup, while the smooth surface of stainless steel prevents adherence of sticky residues.

In aggressive environments like mining or chemical refining, where slurries and abrasive fluids are common, stainless steel well screens demonstrate remarkable wear resistance. Their rigid construction withstands mechanical stress, ensuring consistent performance even under high flow rates. For example, in seawater desalination plants, these screens endure constant exposure to saltwater and sand, yet maintain filtration efficiency for years. This durability is further enhanced by the absence of moving parts, reducing the risk of mechanical failure.

Well screens suppliers also prioritize ease of maintenance. Unlike complex filtration systems that require disassembly for cleaning, vee wire screens can often be backflushed or cleaned in place, minimizing downtime. This feature is particularly valuable in industries like biotechnology, where sterile conditions are paramount. By extending equipment lifespan and reducing maintenance costs, these screens deliver long-term value, aligning with the growing demand for sustainable industrial practices.

Global Reach: Meeting Diverse Needs as Leading Well Screens Suppliers

With a presence spanning over 40 countries across six continents, our expertise as well screens suppliers is rooted in understanding regional and industry-specific challenges. From Asia’s booming chemical manufacturing hubs to Europe’s stringent environmental regulations, vee wire screens are tailored to meet diverse requirements. For instance, in regions with high humidity or saline atmospheres, such as coastal areas in Africa or Oceania, stainless steel well screens are treated with additional anti-corrosion coatings to enhance longevity.

Our global logistics network ensures timely delivery of customized solutions, whether for small-scale water treatment projects in South America or large petrochemical complexes in North America. Collaborating closely with clients, we design wedge wire screens with slot sizes ranging from microns to millimeters, accommodating everything from fine chemical powders to coarse industrial slurries. This flexibility has cemented our reputation as a trusted partner for industries prioritizing quality and reliability.

Furthermore, our commitment to innovation drives continuous improvement. By integrating advanced welding techniques and material science breakthroughs, we ensure that vee wire screens remain at the forefront of filtration technology. This dedication to excellence has enabled us to support industries in achieving regulatory compliance, operational efficiency, and environmental sustainability.

Stainless Steel Well Screens: The Backbone of Modern Chemical Infrastructure

The choice of material is pivotal in determining the success of filtration systems, and stainless steel well screens have become synonymous with reliability in chemical processing. Stainless steel’s innate resistance to rust, heat, and chemical reactivity makes it indispensable for applications requiring hygiene and durability. For example, in food and beverage production, where screens must withstand acidic ingredients like citrus juices or vinegar, vee wire screens prevent contamination while meeting strict sanitary standards.

In oil and gas refineries, wedge wire screens fabricated from duplex stainless steels excel in high-temperature, high-pressure environments. Their ability to resist sulfidation and chloride stress corrosion cracking ensures safe and efficient operations. Similarly, in wastewater treatment plants, these screens filter heavy metals and toxic compounds without degrading, protecting downstream ecosystems.

The versatility of stainless steel well screens extends beyond industrial settings. In agriculture, they are used for irrigation systems to filter sediments, while in construction, they reinforce concrete structures by filtering aggregates. This broad applicability underscores their role as a foundational component across sectors.

Vee Wire Screen Applications in Chemical Processing FAQs

How Do Vee Wire Screens Enhance Safety in Chemical Plants?

Vee wire screens prevent hazardous leaks or contamination by maintaining structural integrity under extreme conditions. Their corrosion-resistant design ensures reliable filtration, reducing the risk of equipment failure.

Why Choose Stainless Steel Well Screens for Food Production?

Stainless steel well screens resist acidic ingredients and bacterial growth, ensuring compliance with food safety standards. Their smooth surface prevents residue buildup, simplifying cleaning processes.

Can Wedge Wire Screens Be Customized for Small-Scale Projects?

Yes, reputable well screens suppliers offer tailored solutions, adjusting slot sizes and dimensions to suit specific applications, from laboratory setups to localized water filtration.

How Do Vee Wire Screens Reduce Environmental Impact?

By extending equipment lifespan and minimizing waste from frequent replacements, vee wire screens support sustainable practices. Their recyclability further aligns with circular economy goals.

What Makes Wedge Wire Screens Low Maintenance?

The self-cleaning design of wedge wire screens reduces clogging, while stainless steel’s durability eliminates the need for frequent repairs. Simple backflushing restores functionality without disassembly.

As a globally trusted well screens supplier, we deliver vee wire screens that combine innovation, durability, and precision. Explore our range of stainless steel well screens and discover how they can transform your chemical processing systems. Visit our website to place your order or consult our experts for a customized solution.