In industrial applications, having the right type of screen for filtration, separation, and sorting is crucial to ensure optimal performance and efficiency. Wedge wire screens, perforated plate screens, perforated mesh, and punch plates are some of the most reliable and durable screening solutions available today. These materials are widely used in industries such as mining, wastewater treatment, food processing, and agriculture, where screening and filtration play an essential role in the overall operation.

The evolution of these screening technologies has enabled industries to improve material flow, enhance product quality, and increase operational efficiency. In this advertrial, we will explore the benefits and applications of wedge wire screens, perforated plate screens, perforated mesh, and punch plates, and discuss how these solutions are essential to modern industrial practices.

Why Клінаватыя драцяныя экраны Are Indispensable in Industrial Filtration

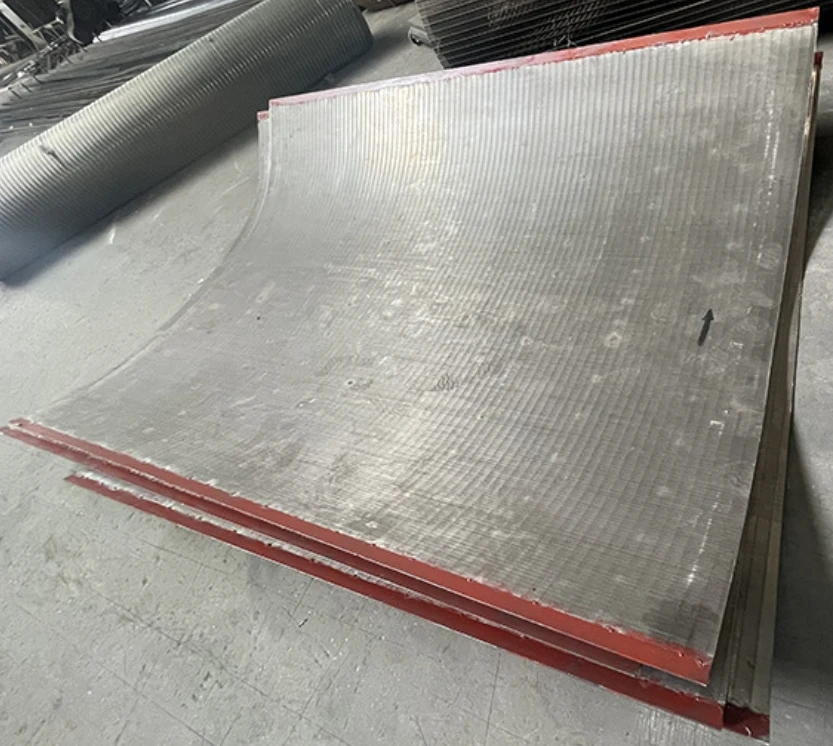

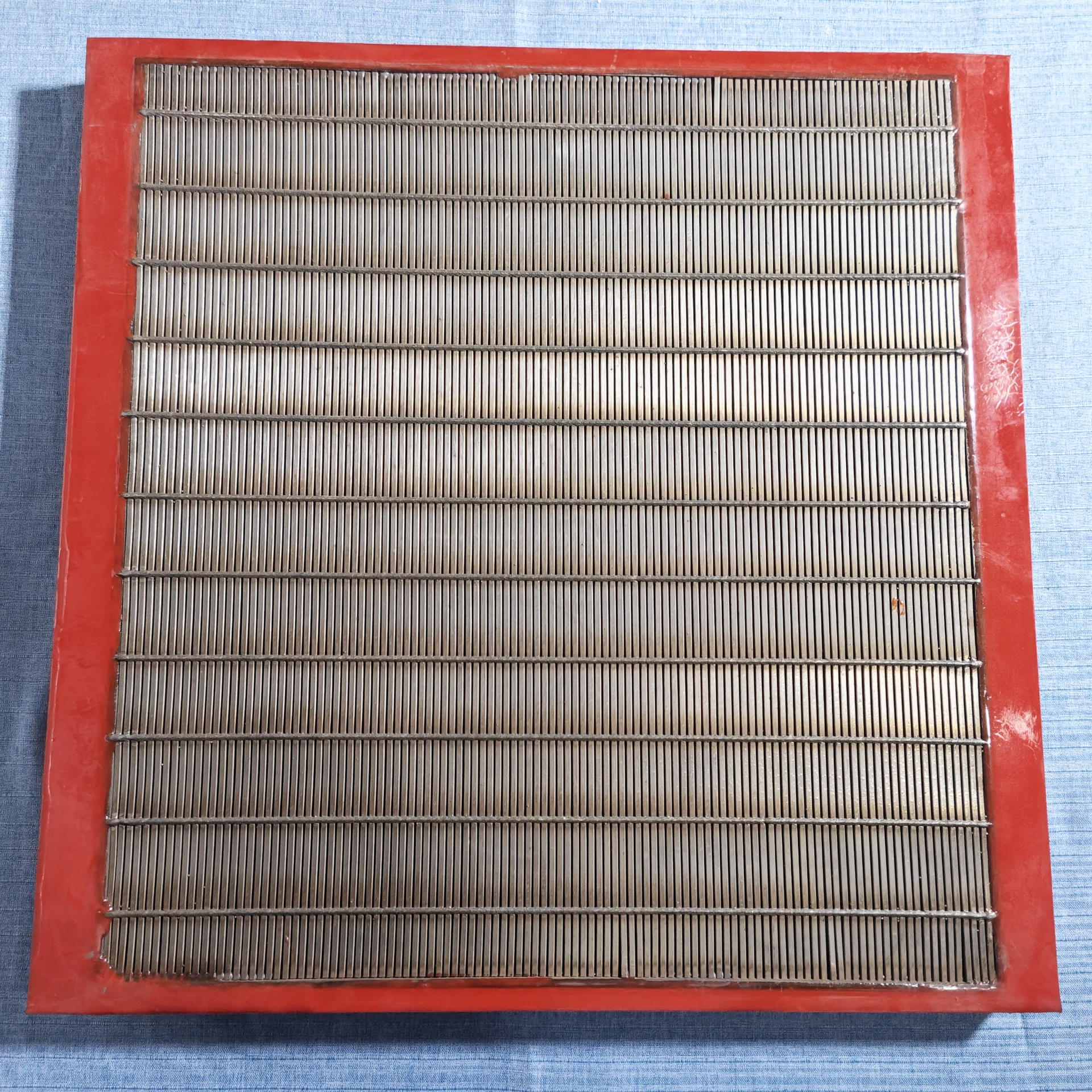

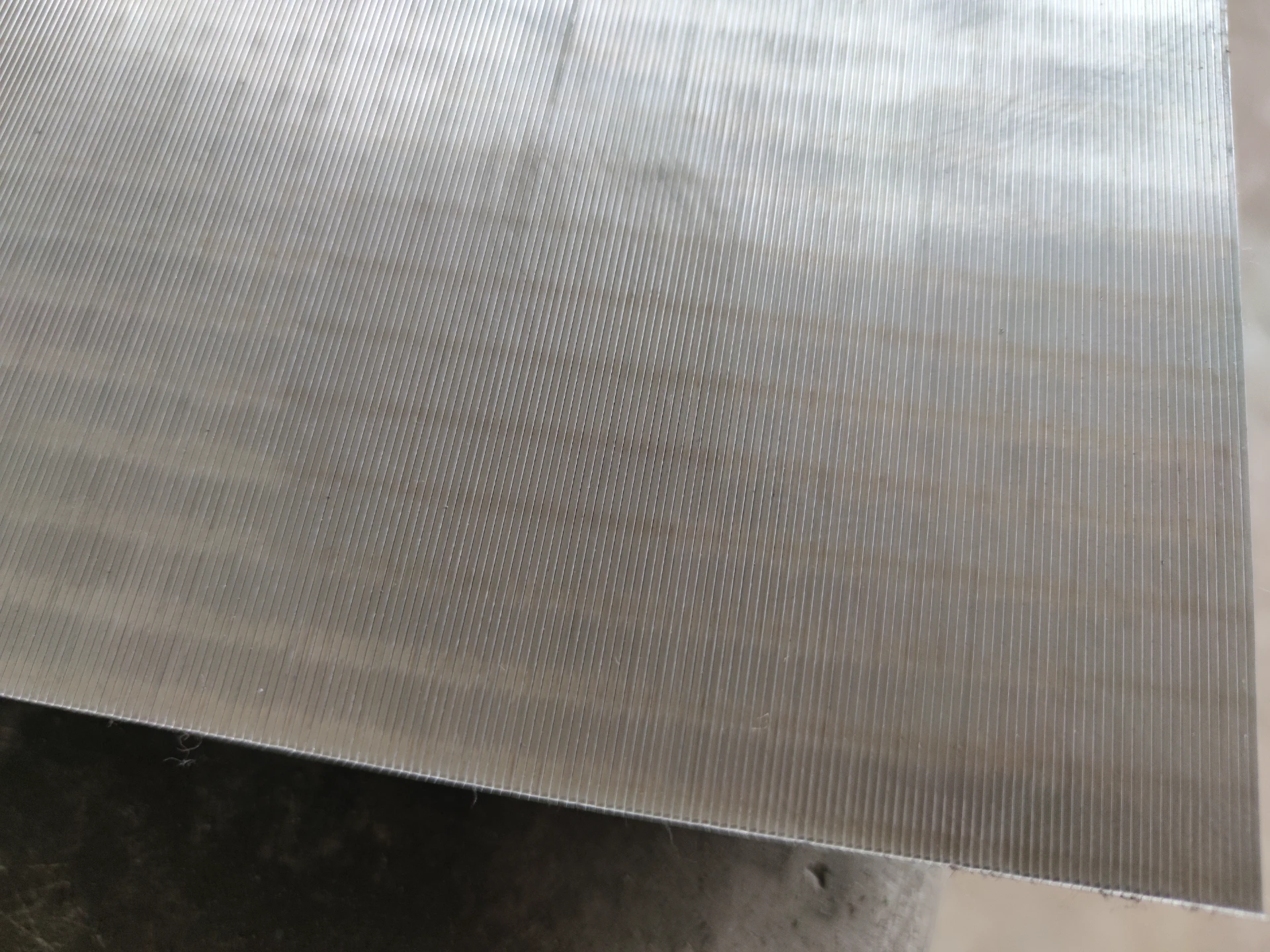

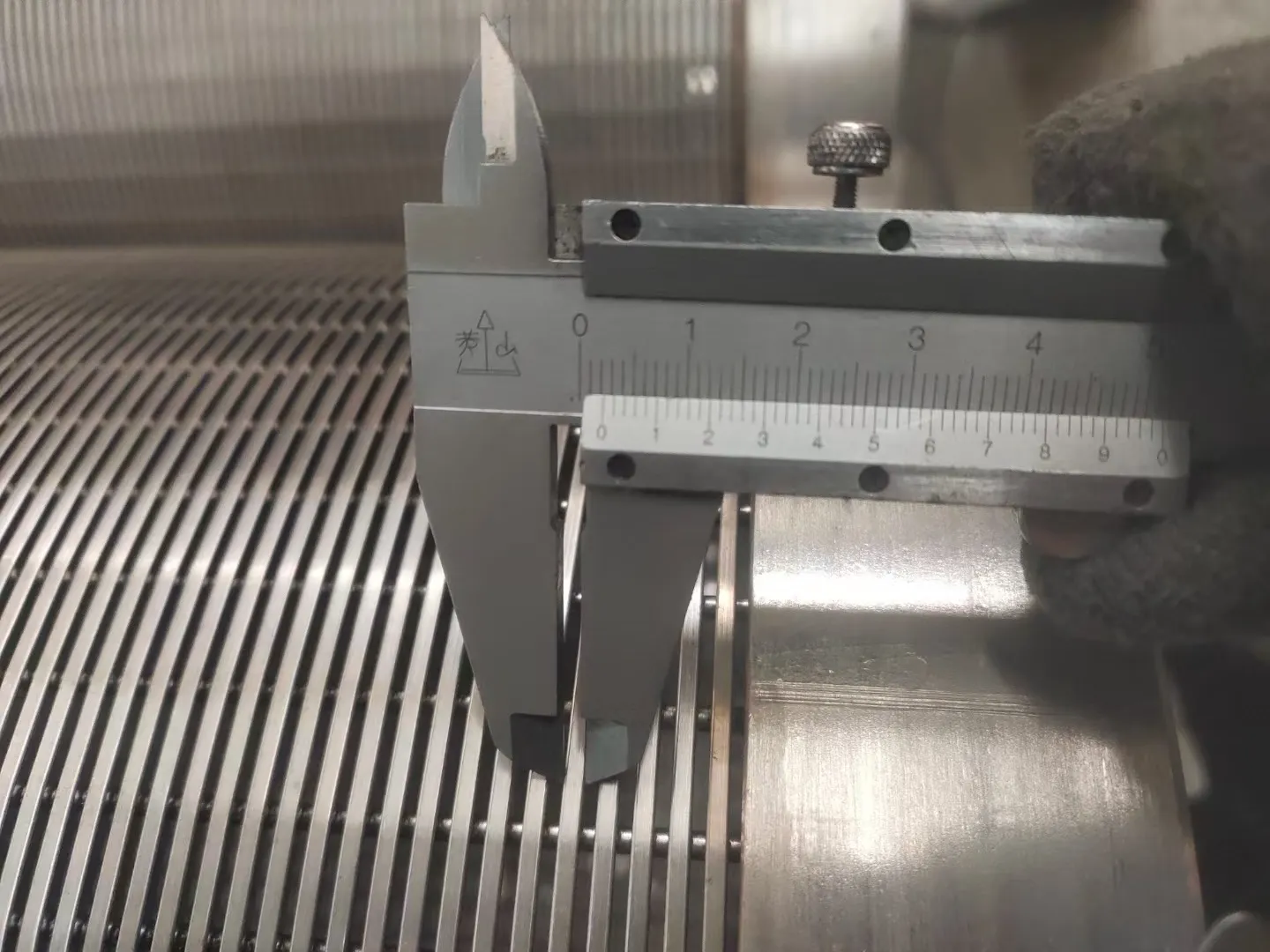

Wedge wire screens are essential tools in various industries, providing efficient and durable filtration and separation. These screens are known for their robust construction and ability to handle high-volume flows of materials. Made from V-shaped, wedge-shaped wire, wedge wire screens are designed to offer high open areas for water or other liquids to pass through, while still effectively separating solid particles.

One of the primary benefits of wedge wire screens is their ability to resist clogging. Their unique wedge-shaped design helps prevent particles from blocking the screen, ensuring a continuous flow of material and reducing maintenance needs. This design also improves the overall efficiency of the filtration or separation process, allowing for higher throughput and reduced downtime.

Another important feature of wedge wire screens is their durability. The wires are welded together in a way that prevents separation and wear, making them ideal for long-term use in harsh industrial environments. Whether used in wastewater treatment plants, mining operations, or food processing, wedge wire screens provide reliable performance even under the most demanding conditions.

These screens are available in various sizes and configurations, which allows them to be customized for specific industrial applications. Whether you need a coarse screen for large particles or a finer screen for more delicate separation, wedge wire screens can be tailored to meet your exact needs.

Advantages of Using Perforated Plate Screens in Industrial Operations

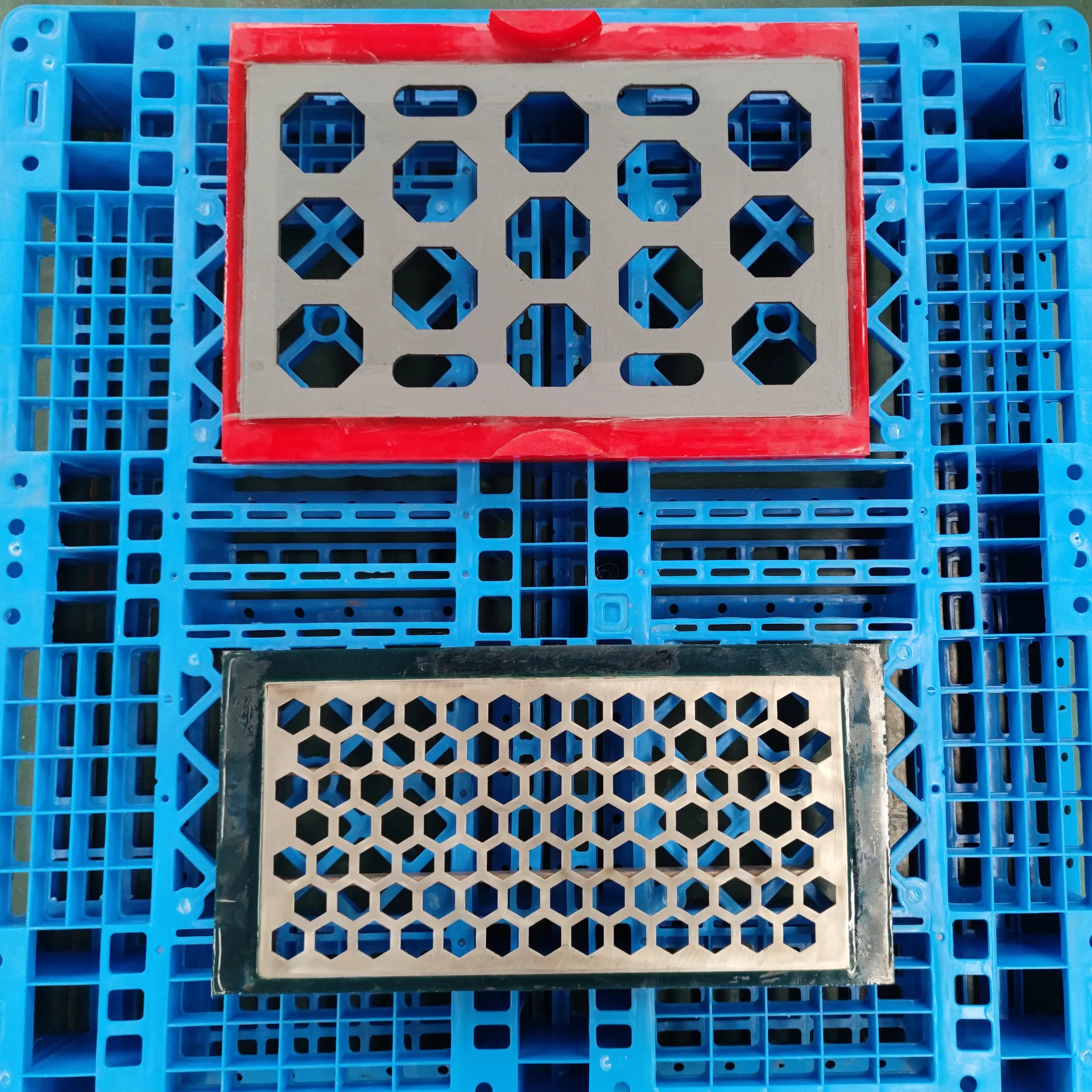

Perforated plate screens are another popular option for industrial filtration and separation. Made from solid metal plates, these screens feature a series of uniformly spaced holes or perforations that allow materials to pass through while retaining larger particles. Perforated plate screens are widely used in industries such as mining, agriculture, and construction, where reliable and efficient material separation is necessary.

One of the main advantages of perforated plate screens is their ability to handle heavy-duty applications. The solid metal construction provides strength and durability, making these screens ideal for industries that deal with large volumes of abrasive materials. Whether you’re dealing with coal, gravel, or other coarse materials, perforated plate screens can provide long-lasting and reliable performance.

The versatility of perforated plate screens also makes them an excellent choice for applications that require specific hole patterns or sizes. The perforations can be customized to match the needs of the material being processed, allowing for precise separation of particles based on size. This makes perforated plate screens ideal for industries that need to separate different materials efficiently, such as in mining, construction, and recycling.

Another benefit of perforated plate screens is their ease of maintenance. Unlike other types of screens that may require frequent cleaning or replacement, perforated plate screens are easy to clean and maintain, ensuring that operations can continue without interruptions. This reduces downtime and helps companies maximize their productivity.

Perforated Mesh: A Flexible Solution for a Variety of Applications

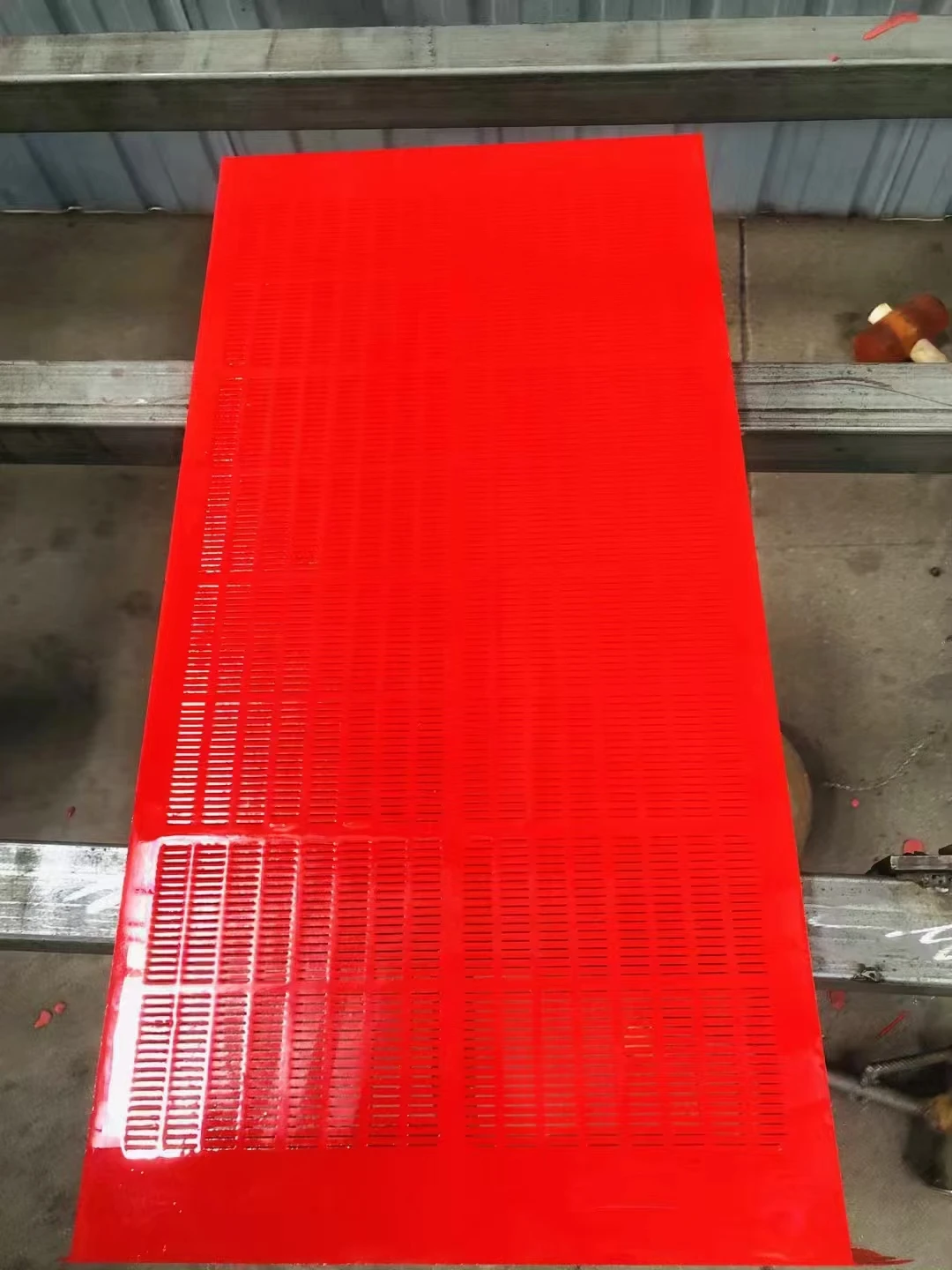

Perforated mesh is a versatile screening material that is used in a wide range of applications, from industrial filtration to architectural designs. Made from thin sheets of metal, perforated mesh features a series of holes or perforations that can vary in size and pattern. This material is used for screening, filtering, and protecting equipment, as well as in decorative applications where a uniform, aesthetically pleasing appearance is desired.

One of the primary advantages of perforated mesh is its flexibility. Available in a variety of materials, including stainless steel, aluminum, and carbon steel, perforated mesh can be customized to suit the specific needs of any application. Whether you’re using it for industrial filtration, air conditioning systems, or architectural facades, perforated mesh provides a durable and reliable solution.

Perforated mesh is also known for its strength and lightweight properties. Despite its thin construction, perforated mesh can withstand heavy loads and harsh environmental conditions. This makes it suitable for industries like mining and construction, where the material must endure rigorous conditions without compromising performance.

Another key advantage of perforated mesh is its ability to provide excellent ventilation and airflow. The holes in the mesh allow air to pass through freely, making it ideal for use in ventilation systems and other applications where air circulation is crucial.

The Role of Punch Plates in Industrial Screening

Punch plates are specialized screening materials that are created by punching holes into a solid plate of metal, resulting in a screen with a unique hole pattern. These screens are typically used in industries that require precise separation of materials, such as in mining, construction, and waste management. Punch plates are available in a variety of materials, including steel and stainless steel, and come in different hole patterns and sizes to meet specific screening requirements.

One of the primary advantages of punch plates is their durability. Made from solid metal, these screens are capable of withstanding heavy-duty use in demanding applications. Whether used in vibrating screens, trommels, or other screening equipment, punch plates can handle abrasive materials and continue to perform effectively over time.

The unique hole patterns of punch plates also provide an efficient and uniform screening process. By customizing the hole size and arrangement, punch plates can be tailored to meet the needs of different applications, ensuring that particles are separated according to size. This precision makes punch plates a valuable tool for industries that require high-performance screening systems.

In addition to their industrial applications, punch plates are also used in architectural and decorative applications, where their unique patterns can enhance the aesthetic appeal of buildings, facades, and other structures. Their versatility, combined with their durability, makes punch plates an essential tool in a wide variety of industries.

Wedge Wire Screens FAQs

What are wedge wire screens used for?

Wedge wire screens are used in industrial filtration and separation processes, especially in mining, wastewater treatment, and food processing. They offer high durability, flexibility, and efficiency in separating materials.

How do perforated plate screens improve material separation?

Perforated plate screens feature uniformly spaced holes that allow for efficient separation of materials based on size. Their solid metal construction provides strength and durability, making them suitable for heavy-duty applications.

Why is perforated mesh considered a versatile screening material?

Perforated mesh is versatile because it can be made from different materials, customized in terms of hole patterns and sizes, and used in a wide range of applications, from industrial filtration to architectural designs.

What are the benefits of using punch plates in industrial screening?

Punch plates are durable and provide precise material separation due to their unique hole patterns. They are ideal for heavy-duty applications in industries like mining, construction, and waste management.

Can wedge wire screens be used in harsh environments?

Yes, wedge wire screens are highly resistant to abrasion and wear, making them suitable for harsh environments where other screens might fail, such as in mining or wastewater treatment plants.