The wedge wire mesh has emerged as a pivotal innovation in modern water management systems, particularly in addressing the global challenge of sustainable water reuse. Unlike traditional filtration methods, which often rely on disposable materials or inefficient designs, wedge wire mesh structures are engineered for longevity and precision. Their unique V-shaped profile ensures consistent flow rates while trapping contaminants, making them ideal for applications ranging from municipal wastewater treatment to industrial process water recycling. By enabling the efficient separation of solids and liquids, these screens reduce the energy required for pumping and processing, thereby lowering the carbon footprint of water treatment facilities.

For industries prioritizing sustainability, wedge wire mesh systems offer a closed-loop solution. For example, in agriculture, they facilitate the reuse of irrigation water by filtering out sediments and organic matter, ensuring cleaner water returns to the ecosystem. In manufacturing, they help recover valuable resources like metals or chemicals from wastewater streams, aligning with circular economy principles. Our globally exported well screens have been instrumental in helping clients across Asia, Europe, and Africa achieve compliance with environmental regulations while minimizing freshwater extraction.

Minimizing Material Waste with Durable Wedge Wire Screen Panels

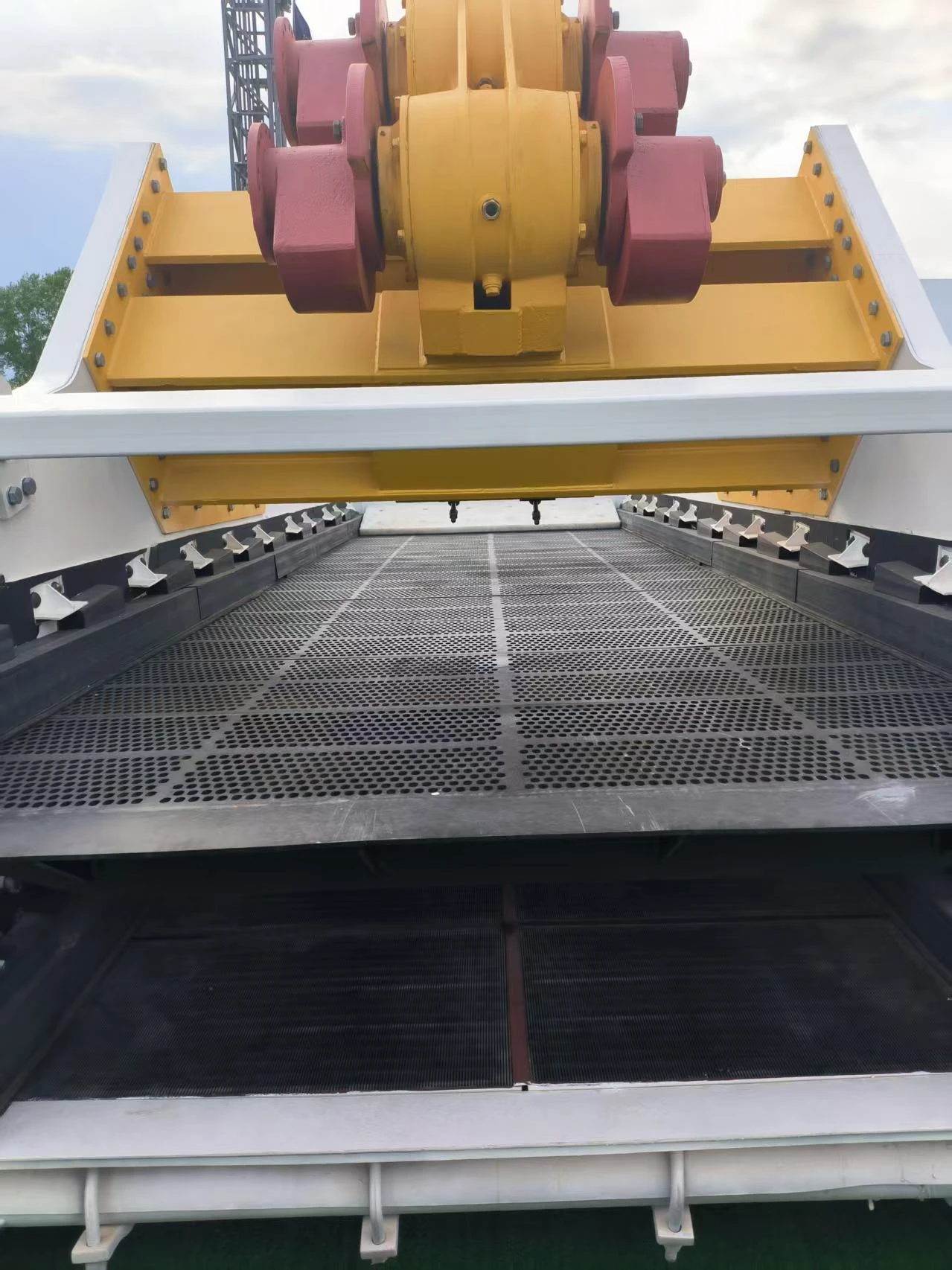

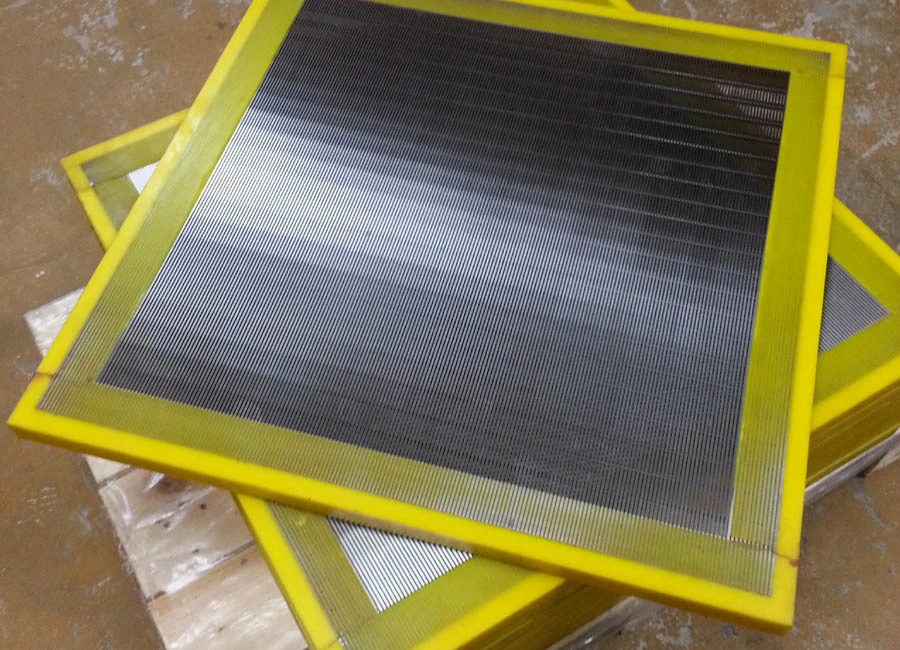

The environmental advantages of wedge wire screen panels extend beyond water reuse to their role in reducing material waste. Traditional screens, often made of woven wire or perforated plates, degrade quickly under high-pressure or abrasive conditions, necessitating frequent replacements. In contrast, wedge wire screen panels are constructed from robust stainless steel or specialized alloys, ensuring decades of service with minimal maintenance. This durability translates to fewer discarded materials in landfills and reduced demand for raw resources.

Moreover, the modular design of wedge wire screen panels allows for easy repairs or upgrades. Instead of replacing an entire system, damaged sections can be individually repaired, further cutting down on waste. In mining operations, for instance, our customized panels have helped clients recover minerals more efficiently while slashing the volume of waste sludge. This approach not only conserves materials but also reduces the environmental disruption caused by mining activities.

Customization Through Versatile Wedge Wire Screen Sizes

One of the most impactful features of wedge wire screen sizes is their adaptability to diverse applications. Available in a wide range of slot openings, thicknesses, and diameters, these screens can be tailored to meet specific filtration requirements. For municipal water treatment plants, larger wedge wire screen sizes are ideal for pre-treatment stages, removing coarse debris before finer filtration. Conversely, smaller slot sizes excel in desalination plants, where they prevent salt crystals from clogging membranes.

The ability to customize wedge wire screen sizes also supports localized environmental solutions. In arid regions like parts of Africa and the Middle East, our screens have been integrated into groundwater recharge systems, filtering stormwater to replenish aquifers. In coastal areas, they protect marine ecosystems by filtering out microplastics and oil residues from industrial runoff. By aligning screen specifications with regional challenges, we empower clients to implement targeted sustainability strategies.

The Role of V-Wire Screens in Enhancing Filtration Efficiency

At the heart of the wedge wire mesh system lies the V-wire screen, a design marvel that maximizes filtration efficiency. The V-shaped wires create a smooth, tapered surface that resists clogging, even when handling high-viscosity fluids or fibrous materials. This efficiency reduces the need for backwashing or chemical cleaning, which in turn lowers water and energy consumption. In food and beverage industries, V-wire screens ensure hygienic processing by preventing bacterial buildup, aligning with both environmental and food safety goals.

The structural integrity of V-wire screens also makes them suitable for extreme environments. In oil refineries, they withstand corrosive chemicals and high temperatures, ensuring reliable performance without frequent replacements. This resilience not only reduces material waste but also enhances operational safety by minimizing downtime.

FAQs: Wedge Wire Mesh and Sustainable Filtration

How do wedge wire screens benefit households?

Wedge wire screens are not just for industrial use—they can improve home water systems too. For instance, rainwater harvesting systems equipped with these screens filter out leaves and debris, ensuring cleaner water for gardening or household use. Their durability means homeowners avoid frequent replacements, saving money and reducing plastic waste from disposable filters.

Why choose wedge wire screen panels over plastic alternatives?

Unlike plastic screens, wedge wire screen panels are non-toxic and recyclable. They do not leach harmful chemicals into water, making them safer for long-term use in drinking water systems. Additionally, their stainless steel construction ensures they won’t degrade into microplastics, which harm aquatic ecosystems.

Can wedge wire screen sizes be adjusted for small projects?

Absolutely! Whether you’re building a backyard pond or a community well, wedge wire screen sizes can be customized to fit your needs. Smaller screens are perfect for DIY water filtration projects, offering professional-grade results without industrial complexity.

Are V-wire screens suitable for saltwater environments?

Yes, V-wire screens made from corrosion-resistant alloys excel in marine applications. They’re widely used in desalination plants and aquaculture systems to filter seawater without rusting, ensuring sustainable operations in coastal regions.

How do I maintain wedge wire mesh systems?

Maintenance is simple: periodic rinsing with water is usually sufficient to remove trapped particles. For heavy-duty applications, a soft brush can dislodge stubborn debris. Their low-maintenance design makes them ideal for remote or resource-limited areas.

For over a decade, our wedge wire mesh solutions have empowered industries and communities worldwide to achieve environmental goals. With exports to 40+ countries, we combine global expertise with localized support, delivering screens that last. Visit our website to explore customizable wedge wire screen panels and join the movement toward sustainable water management.