Flip Flow Screen for Sale: The Game-Changer for High-Efficiency Screening in Coal and Mining Industries

When it comes to achieving precise material separation in challenging environments, the flip flow screen for sale is revolutionizing the coal and mining industries. Designed with cutting-edge technology, it delivers superior shock resistance, exceptional screening performance, and full compliance with international standards.

International Certification Standards of Flip Flow Screen

For any serious industrial operation, ensuring that equipment meets stringent international certification standards is non-negotiable. The flip flow screen is no exception. Top-tier models are manufactured in accordance with ISO 9001 quality management systems, CE marking for European markets, and often adhere to ASTM and DIN material standards for durability and safety.

Especially for industries operating globally, investing in a flip flop screen for coal that meets such certifications guarantees optimal performance, product reliability, and compliance with health and safety regulations. High-end flip flow screen systems are often tested for corrosion resistance, load-bearing capacity, and environmental resilience, ensuring long-term operational excellence even under the most demanding conditions.

Choosing a flip flow screen manufacturer committed to certified production not only enhances screening efficiency but also boosts the credibility and sustainability of your project.

Shockproof Performance of Flip Flow Screen

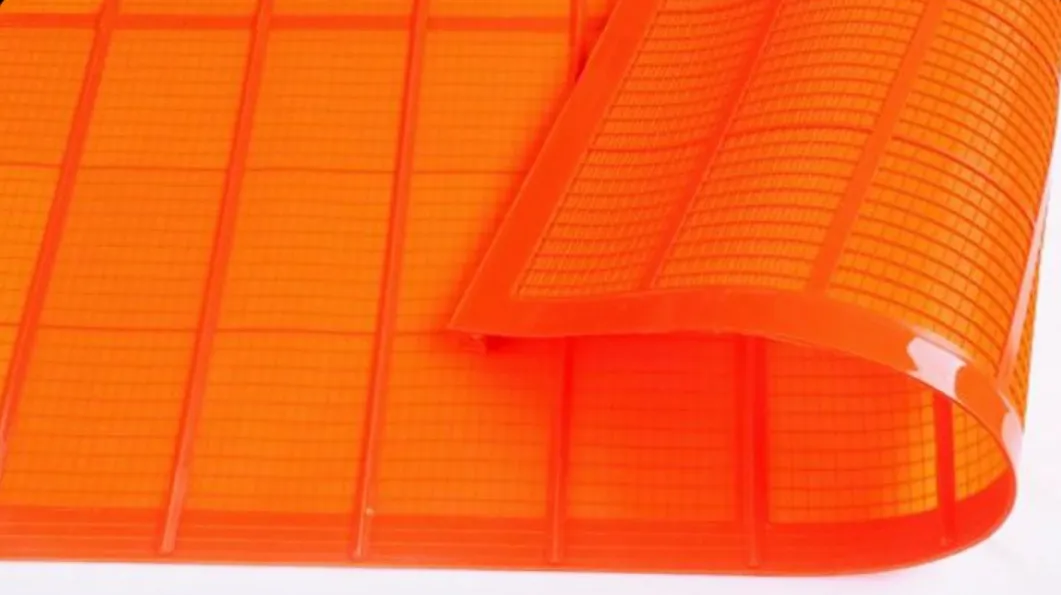

One of the most standout features of the flip flow screen is its unparalleled shockproof ability. Unlike traditional vibratory screens, which often suffer from material fatigue and structural stress, the flip flop screen for coal is engineered with elastic screen mats that work in conjunction with dynamic frames.

During operation, the frame and screen mats undergo rapid acceleration and relaxation, effectively absorbing impact forces without transferring excessive load to the machine structure. This unique design enables the flip flow screen to handle large, heavy, and damp material loads with minimal risk of cracking or downtime.

In underground coal mining, where impact loads from large rocks and high-moisture fines are routine, the rugged shockproof design of a flip flow screen for sale ensures consistent, reliable performance. This durability minimizes maintenance needs, prolongs service life, and keeps operational costs under tight control.

Market Demand for Flip Flow Screen

Driven by the booming coal, mining, and recycling industries, the market demand for the flip flow screen is growing at an unprecedented pace. Particularly in countries investing heavily in energy resources, infrastructure, and raw material processing, the need for advanced separation equipment is critical.

The flip flop screen for coal has carved out a significant niche thanks to its ability to tackle difficult screening tasks—especially moist, sticky, or fine materials that traditional screens struggle with. Companies are increasingly seeking durable, high-performance solutions that can keep production lines moving efficiently without frequent cleaning or downtime.

Moreover, the rising emphasis on environmental protection and efficient resource utilization has fueled the adoption of flip flow screen for sale products. They offer not only higher throughput and precision but also better adaptability to variable material conditions, making them a must-have for modern industrial operations.

Selecting the right flip flow screen manufacturer with a proven track record of innovation and reliability is crucial for capitalizing on these market opportunities and staying ahead of the competition.

Why Flip Flow Screen Outperforms Traditional Screening Equipment

The flip flow screen is a technological leap over traditional fixed or vibratory screens. Its flexible screen mats, paired with optimized dynamic forces, create a self-cleaning effect that drastically reduces clogging and blinding issues.

In practical terms, this means the flip flop screen for coal can maintain peak performance even when screening wet, sticky, or highly variable materials—scenarios that would typically cause conventional screens to fail or require frequent stoppages for cleaning.

Additionally, the modular design of the flip flow screen for sale allows for easy maintenance and screen mat replacement, minimizing downtime and reducing labor costs. Enhanced energy efficiency is another bonus, as the screen’s dynamic movement system requires less power to operate than many older screening technologies.

Leading flip flow screen manufacturer designs also include smart control systems for vibration monitoring and predictive maintenance, offering operators unprecedented control and insight into their screening operations.

Flip Flow Screen FAQs

What international standards should a flip flow screen meet?

A high-quality flip flow screen should comply with ISO 9001, CE certifications, and ASTM or DIN standards for durability, safety, and operational excellence.

How shockproof is a flip flop screen for coal?

The flip flop screen for coal is engineered with dynamic frames and flexible mats that absorb and dissipate shock loads, providing outstanding resistance to heavy impact and material fatigue.

Why is the market demand for flip flow screens increasing?

The demand for flip flow screen for sale products is growing due to the need for efficient separation of wet, sticky, or fine materials in industries such as coal mining, recycling, and mineral processing.

How does a flip flow screen differ from traditional screening equipment?

The flip flow screen offers self-cleaning action, higher throughput, better handling of difficult materials, lower maintenance, and superior shock absorption compared to traditional vibrating screens.

What should I look for in a flip flow screen manufacturer?

When selecting a flip flow screen manufacturer, prioritize companies with certified production standards, proven durability, customization options, and a strong reputation for after-sales support.