Filtration plays a critical role in many industries, whether it's in the processing of food, chemicals, pharmaceuticals, or wastewater. Two essential components that ensure efficient and effective separation in centrifugation systems are centrifuge sieves and centrifuge baskets. These devices are integral to industrial filtration, providing the precision and speed needed to separate solids from liquids or gases. As industries demand greater filtration efficiency, understanding the importance and applications of these components becomes crucial.

Centrifuge sieves and centrifuge baskets offer innovative solutions that enable faster processing times and enhanced quality. These devices are designed to improve operational workflows, reduce downtime, and increase the productivity of separation processes. The combination of high-speed centrifugation with precision filtration ensures that industries can achieve higher yields with minimal waste. In this article, we will explore how centrifuge sieves and centrifuge baskets are revolutionizing industrial filtration systems, their applications, and why they are indispensable in many sectors.

The Role of Centrifuge Sieves in Separation Processes

Centrifuge sieves are an essential part of modern centrifugation systems, used primarily to separate solid particles from liquids or gases. They are designed with precise mesh sizes, enabling them to filter particles with a high level of accuracy. The primary function of a centrifuge sieve is to allow liquids to pass through while trapping solids, ensuring that the output is free from unwanted particles.

The key advantage of centrifuge sieves lies in their efficiency. These sieves can operate at high speeds, enabling rapid filtration and separation. Their design allows for a high surface area, which ensures that the separation process is thorough and quick. Centrifuge sieves are commonly used in industries like chemical manufacturing, wastewater treatment, and food processing, where precision in separating different substances is critical.

Centrifuge sieves also come with various customization options, such as different mesh sizes, materials, and coatings. These options allow for tailoring the sieve to specific processes and materials, ensuring optimal performance. Whether dealing with fine particles or larger solids, centrifuge sieves can be adapted to meet the requirements of a wide range of filtration processes.

Another key feature of centrifuge sieves is their ability to withstand harsh operating conditions. Built with durable materials such as stainless steel or titanium, these sieves are resistant to wear and corrosion, making them ideal for use in industries where harsh chemicals or extreme temperatures are present. This durability ensures that the sieves last longer, offering cost-effective performance over time.

The Efficiency of Centrifuge Baskets in Industrial Filtration

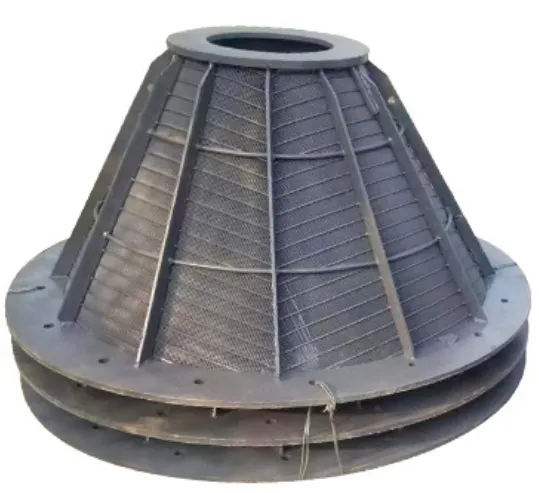

Centrifuge baskets are another essential component of the centrifugation system. These baskets hold the material to be filtered while the centrifuge spins at high speeds, allowing the solid particles to be separated from the liquid. The centrifuge basket plays a critical role in the filtration process by holding the material securely while the centrifugal force acts to separate the solids from the liquids.

A major benefit of centrifuge baskets is their ability to handle large volumes of material, making them ideal for high-capacity filtration systems. They are designed to accommodate a variety of substances, ranging from fine powders to larger, denser solids. This makes them versatile and capable of handling a wide range of materials across different industries, including chemical processing, pharmaceutical production, and food and beverage manufacturing.

The design of centrifuge baskets is engineered to optimize the separation process. They are typically perforated or slotted, allowing liquids to pass through while retaining the solid particles. This design ensures that the centrifuge works efficiently and effectively, with minimal downtime for maintenance or cleaning. Additionally, centrifuge baskets are designed to maximize the use of centrifugal force, ensuring that materials are separated quickly and effectively.

Another key advantage of centrifuge baskets is their ability to reduce operating costs. By providing efficient separation and reducing the need for additional filtration steps, these baskets help improve the overall efficiency of the filtration process. This reduction in operational steps leads to lower energy consumption and less waste, making centrifuge baskets a cost-effective choice for industries looking to optimize their filtration processes.

Comparing Centrifuge Sieves and Centrifuge Baskets: Which is Right for Your Needs?

While both centrifuge sieves and centrifuge baskets play important roles in the filtration process, they serve slightly different functions. Understanding the distinction between these two components will help industries choose the right one based on their specific filtration needs.

Centrifuge sieves are typically used for the finer separation of solids from liquids. They are ideal for processes where small particles need to be removed with high precision. On the other hand, centrifuge baskets are better suited for larger quantities of material and are often used in processes that require the separation of larger particles or where high-volume filtration is required.

When deciding between centrifuge sieves and centrifuge baskets, it is essential to consider factors such as the material being processed, the particle size, and the flow rate of the system. If your process requires separating fine particles from a liquid, centrifuge sieves are the best option. However, if you need to handle larger volumes or thicker materials, centrifuge baskets are more suitable.

Many filtration systems will actually use both centrifuge sieves and centrifuge baskets in combination to achieve the most efficient separation. For instance, a centrifuge basket may first handle the bulk separation of solids, while a centrifuge sieve can refine the process to filter out smaller particles. This combination ensures that both fine and coarse materials are effectively separated, resulting in cleaner output and higher efficiency.

Why Industries Choose Centrifuge Sieves and Centrifuge Baskets for Efficient Filtration

The use of centrifuge sieves and centrifuge baskets has become widespread due to their ability to enhance the filtration process in industries that demand high efficiency and precision. These components offer a range of benefits that make them essential tools in various sectors.

One of the main reasons industries choose centrifuge sieves and centrifuge baskets is their ability to handle large volumes of material while maintaining a high level of separation accuracy. This is particularly important in industries such as food processing, where the separation of fine solids from liquids is a critical part of production. In wastewater treatment, these components are used to separate contaminants from water, ensuring the water meets environmental standards before being released back into nature.

Another reason for their popularity is their customization options. Centrifuge sieves and centrifuge baskets can be tailored to meet specific filtration needs, whether it's for handling particular materials, achieving a desired flow rate, or ensuring compatibility with other equipment. This customization makes these components suitable for a wide range of applications, improving the overall efficiency of the filtration process.

Moreover, the durability of centrifuge sieves and centrifuge baskets ensures long-lasting performance in tough environments. Made from corrosion-resistant materials like stainless steel, these components can withstand the rigors of continuous operation and harsh operating conditions, providing excellent value over time.

Centrifuge Sieves FAQs

What are centrifuge sieves used for?

Centrifuge sieves are used for separating solid particles from liquids or gases in various industrial processes, such as wastewater treatment, chemical processing, and food production.

How do centrifuge baskets aid in filtration?

Centrifuge baskets hold the material to be filtered while the centrifuge spins, allowing centrifugal force to separate the solids from the liquids.

Can centrifuge baskets handle large volumes of material?

Yes, centrifuge baskets are designed to handle large volumes of material, making them ideal for high-capacity filtration systems.

What is the difference between centrifuge sieves and centrifuge baskets?

Centrifuge sieves are used for fine filtration, while centrifuge baskets are used for larger volumes and coarser materials. Both play a vital role in the filtration process.

Why should industries choose centrifuge sieves and centrifuge baskets?

These components offer high efficiency, customization, and durability, making them essential for industries that require precise and high-capacity filtration.