For industries seeking high-efficiency solid-liquid separation solutions, rotary drum screens offer unmatched performance, reliability, and operational ease. Whether you're dealing with industrial, municipal, or commercial wastewater, investing in advanced rotary drum screens guarantees exceptional results and low maintenance over time.

Differences Between Fixed Drum Screens and Rotary Drum Screens

Understanding the distinction between fixed drum screens and rotary drum screens is essential when selecting the right solution for wastewater treatment projects. Fixed drum screens are stationary, meaning the water and solids must move past the screen purely by the flow's force. This often leads to clogging, higher maintenance, and limited screening capacity.

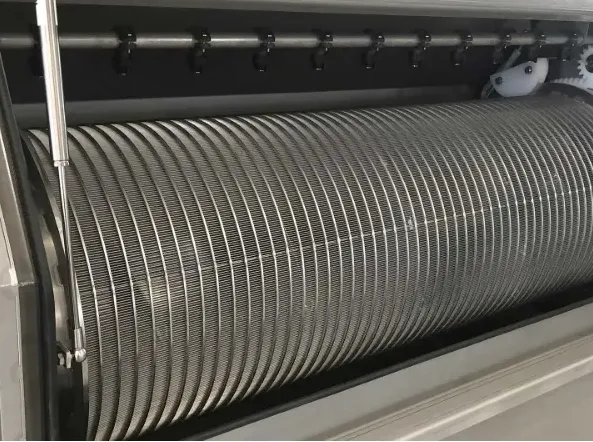

In contrast, rotary drum screens feature a continuously rotating drum that mechanically separates solids from liquids. The rotating motion not only increases separation efficiency but also ensures the screen surface remains clear of debris, providing continuous and effective operation. This self-cleaning capability makes drum screen wastewater systems highly suitable for environments where high solids loads or sticky materials are common.

Additionally, rotary drum screens can handle higher throughput volumes, offer more consistent performance, and have longer service lives compared to their fixed counterparts. Selecting equipment from top rotary drum screen manufacturers ensures even greater reliability and tailored solutions for complex wastewater challenges.

Rotary Drum Screens vs Vibrating Screens: Key Differences

Choosing between rotary drum screens and vibrating screens depends largely on the nature of the material and the operational requirements. While vibrating screens use mechanical vibration to separate materials, they are more suitable for dry, granular substances and are less effective in wet environments like wastewater treatment.

Rotary drum screens, on the other hand, are purpose-built for wet, sludgy, or fluid-heavy environments. In drum screen wastewater applications, the rotating mechanism ensures that water passes efficiently through the mesh while solids are caught and removed automatically. Unlike vibrating screens, rotary drum screens provide a gentler screening process that reduces wear and tear, leading to longer equipment life.

Moreover, rotary drum screens typically consume less energy and offer quieter operation, making them ideal for municipal sewage plants, food processing waste streams, and industrial wastewater systems. When high moisture content and consistent solid-liquid separation are priorities, rotary drum screens clearly outperform traditional vibrating screens.

Suitable Sewage Types for Rotary Drum Screens

One of the major strengths of rotary drum screens is their versatility across various types of sewage treatment. These systems are particularly effective for pre-treatment in municipal wastewater plants, where they remove hair, fibers, and fine solids before biological processing.

Drum screen wastewater systems are also highly effective in treating food and beverage industry effluents, meat processing wastewater, paper mill water discharges, and textile manufacturing waste. Wherever there are floating solids, fibrous material, or heavy sludge loads, rotary drum screens can deliver exceptional performance.

By partnering with experienced rotary drum screen manufacturers, clients can choose models with customized drum perforations, screen openings, and rotation speeds to perfectly match their specific application requirements. Whether you are treating primary, secondary, or tertiary wastewater streams, rotary drum screens provide a high-efficiency, low-maintenance solution.

Why Choosing the Right Rotary Drum Screen Manufacturer Matters

Investing in premium-quality rotary drum screens starts with selecting the right supplier. Top-tier rotary drum screen manufacturers offer cutting-edge designs, precision fabrication, and materials like stainless steel that resist corrosion and wear.

Leading manufacturers also provide additional engineering features such as integrated spray bars for enhanced self-cleaning, automated control systems for better process integration, and modular designs for easy maintenance access.

Moreover, trusted rotary drum screen manufacturers can tailor designs for specific flow rates, solids loading, and environmental conditions, ensuring that each installation maximizes operational efficiency and minimizes downtime.

Selecting a reliable manufacturer not only ensures top-notch rotary drum screens but also comes with access to ongoing technical support, fast delivery of spare parts, and expert consultation for system upgrades and optimization.

Rotary Drum Screens FAQs

What are the main advantages of rotary drum screens over fixed drum screens?

Unlike fixed screens, rotary drum screens rotate continuously to prevent clogging, improve solids capture rates, and provide consistent operation with minimal manual cleaning.

How do rotary drum screens differ from vibrating screens?

Rotary drum screens are designed for wet environments like drum screen wastewater treatment, offering smoother separation with lower energy consumption compared to the dry material-focused vibrating screens.

What types of sewage are best suited for rotary drum screens?

Rotary drum screens are ideal for municipal wastewater, food industry effluents, paper mill discharges, textile wastewaters, and any fluid with suspended solids or fibrous materials.

Why is it important to choose reputable rotary drum screen manufacturers?

Top rotary drum screen manufacturers ensure high-quality construction, custom solutions, reliable after-sales service, and equipment that meets rigorous industrial and environmental standards.

Can rotary drum screens be customized for specific wastewater needs?

Absolutely. Leading suppliers of rotary drum screens can adjust drum size, screen perforation, rotation speed, and additional features like spray bars to perfectly match client requirements.