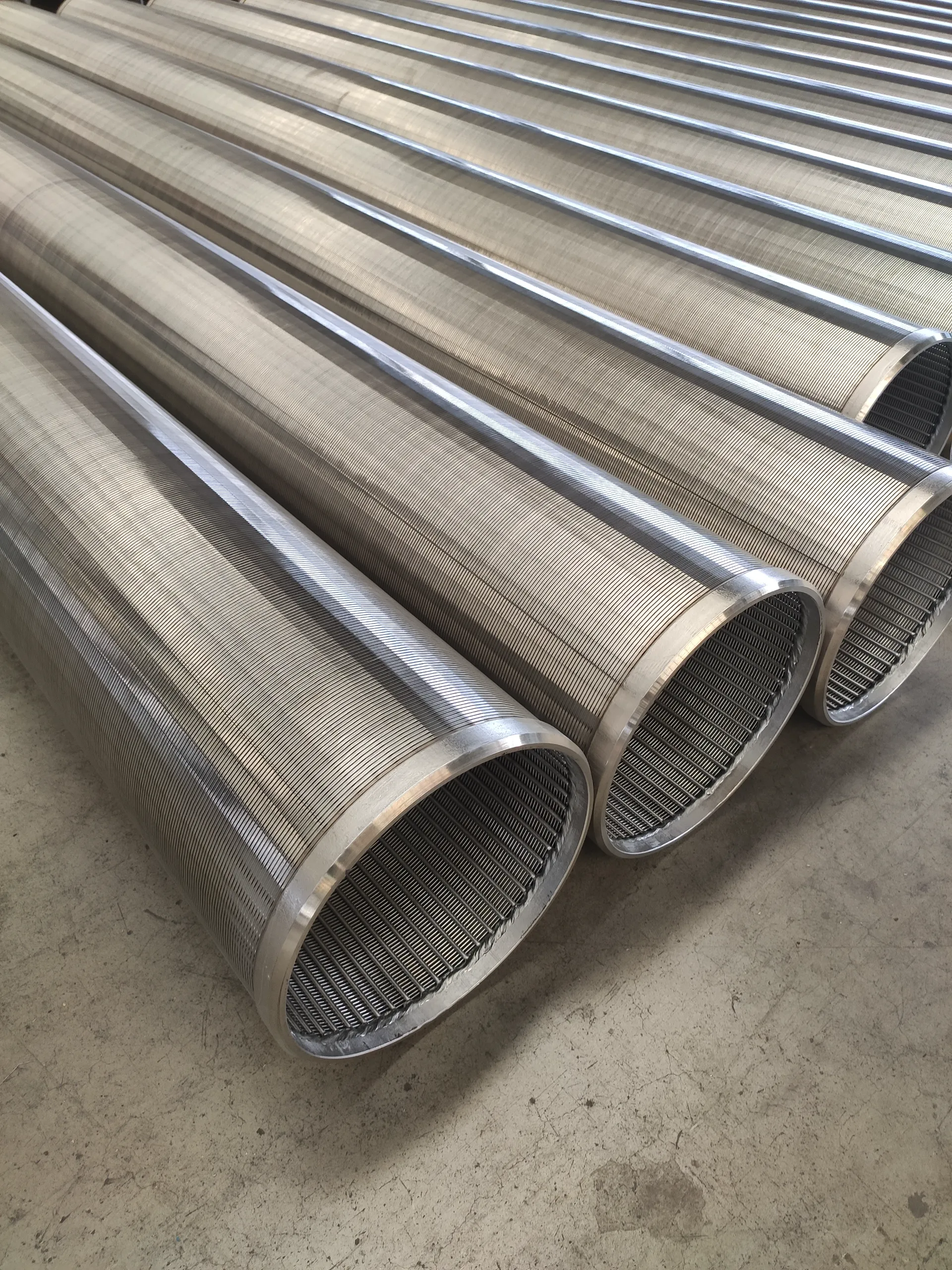

When installing or maintaining a water well, one of the most crucial components is the well screen pipe. This essential part ensures that water flows efficiently into the well while preventing sediments, sand, and debris from entering the system, which could damage the pump and other equipment. The right well screen pipe guarantees both the protection of the well components and optimal water flow.

A well screen pipe typically consists of a pipe covered with a screen that filters out unwanted particles as water enters the well. The choice of materials and design of the pipe is essential for the well’s long-term performance. Whether for domestic, agricultural, or industrial use, selecting the right well screen pipe ensures that the well operates efficiently with minimal maintenance.

The benefits of choosing the correct well screen pipe include reduced maintenance costs, improved water quality, and longer system lifespan. A poor-quality screen, however, could cause clogging, sediment buildup, or even mechanical failure, leading to costly repairs and downtime. Hence, when planning a well system, it’s essential to choose high-quality components, including a well screen pipe, from trusted suppliers.

Why Stainless Steel Well Screens Are a Durable and Reliable Choice

One of the best materials used for stainless steel well screens is stainless steel itself. Stainless steel well screens are highly resistant to corrosion and can withstand harsh environmental conditions. Whether your well is located in a high-salinity coastal region or an industrial area, stainless steel well screens provide long-term durability and reliable performance.

Stainless steel well screens are designed to resist wear and tear, even in areas with high water pressure or challenging soil conditions. The material’s resistance to corrosion means that stainless steel well screens last much longer than screens made from other materials, such as galvanized steel or plastic, which are more prone to degradation over time.

Additionally, stainless steel well screens are available in a variety of mesh sizes and designs, making them highly customizable to suit different well depths and water quality requirements. This versatility makes stainless steel an ideal choice for a wide range of applications, from drinking water wells to industrial water extraction.

Submersible Well Pump Screen: Essential for Maintaining Water Flow

A submersible well pump screen is another key component in a water well system, particularly for deep wells. The submersible well pump screen serves as a filtration system, preventing sand, sediment, and other debris from entering the pump and clogging the system. This ensures that the pump operates smoothly without interruptions, extending its lifespan and reducing maintenance costs.

The submersible well pump screen is often attached to the pump itself and is submerged at the bottom of the well. Because it is constantly in contact with the water source, the submersible well pump screen needs to be made from durable materials, such as stainless steel or other corrosion-resistant alloys, to ensure its effectiveness.

A high-quality submersible well pump screen can drastically reduce the frequency of pump maintenance and repairs, providing long-term reliability. When selecting a submersible well pump screen, it’s essential to choose one that matches the specific size and depth of your well, as well as the type of water you’re extracting.

The Role of Screen Pipe for Borewell in Water Well Construction

For borewell applications, the screen pipe for borewell is crucial in maintaining the efficiency of the water well. This type of screen pipe is designed to fit into narrow, deep wells, preventing the infiltration of sand, silt, and other particles that could clog the water flow. The screen pipe for borewell ensures that only clean water enters the well pump, making it an essential component in borewell installations.

The design of the screen pipe for borewell typically includes perforations or mesh that allow water to pass through while keeping sediment out. The screen pipe for borewell can be made from various materials, including stainless steel, PVC, and other corrosion-resistant materials, depending on the conditions of the well.

Properly installing a screen pipe for borewell ensures that the well maintains optimal water flow and minimizes the risk of contamination. Whether you’re drilling a new borewell or replacing an old screen, choosing the right screen pipe for borewell will ensure a successful and efficient water extraction process.

Understanding the Importance of Well Screen Replacement

Over time, the components of a water well, including the well screens, may become worn out or clogged, making well screen replacement necessary to maintain proper water flow. Well screen replacement is particularly important for wells that have been in operation for several years, as screens can become damaged due to sediment buildup, corrosion, or mechanical stress.

During well screen replacement, it is important to choose a high-quality replacement screen that fits the well's specifications. This will ensure that the new screen restores the well’s performance and longevity. Well screen replacement is typically performed by professionals who can assess the condition of the existing screen and recommend the most appropriate replacement option.

Choosing the right material for well screen replacement is also crucial. For instance, stainless steel well screens offer superior durability and corrosion resistance, making them an excellent choice for replacement in wells that deal with challenging environmental conditions. Regular well screen replacement helps prevent clogging, ensures optimal water quality, and reduces the need for frequent maintenance.

Well Screen Replacement FAQs

What is the purpose of a well screen pipe?

A well screen pipe helps filter out sediments and debris from the water entering the well, ensuring clean water flows into the system while preventing clogging and damage to the pump.

Why are stainless steel well screens a good choice for water wells?

Stainless steel well screens are highly durable, resistant to corrosion, and can withstand harsh environmental conditions, making them an ideal material for long-lasting and efficient water wells.

How does a submersible well pump screen function?

A submersible well pump screen filters out sand, sediment, and debris from the water before it enters the pump, ensuring that the pump operates smoothly and reduces the need for frequent maintenance.

What is the role of a screen pipe for borewell?

The screen pipe for borewell prevents sediment and debris from entering the borewell and clogging the water flow, ensuring clean water enters the pump for extraction.

When should I consider well screen replacement?

Well screen replacement is necessary when the screen becomes clogged, corroded, or damaged over time. Regular replacement ensures the well operates efficiently and prevents long-term damage to the system.