In the world of industrial filtration and material separation, efficiency is key. Whether you're in mining, wastewater treatment, or material processing, the need for durable and efficient screening solutions is crucial. The use of polyurethane sieve plates has become a game changer in this space, offering unmatched performance in separating materials, particularly when it comes to demanding dewatering applications. These innovative sieve plates are engineered to provide better durability, performance, and efficiency.

In this article, we will explore the significant advantages of polyurethane sieve plates, how urethane screen panels are revolutionizing the industry, and why dewatering screen panels and dewatering screens are essential for your filtration processes.

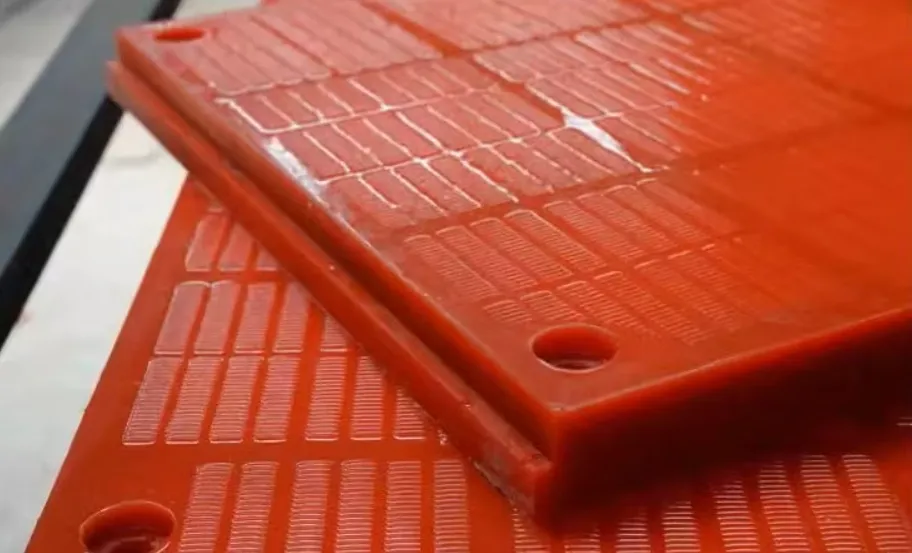

The Durability and Efficiency of Polyurethane Sieve Plates

One of the most outstanding features of polyurethane sieve plates is their exceptional durability. Unlike traditional metal sieve plates, polyurethane is highly resistant to abrasion, corrosion, and wear. This makes polyurethane sieve plates ideal for industries that process tough materials such as minerals, ores, and other abrasive substances. The longevity of polyurethane sieve plates reduces downtime and maintenance costs, which is crucial for industries where continuous operation is vital.

Polyurethane sieve plates are designed to handle extreme operating conditions. Whether it’s exposure to chemicals, high temperatures, or the mechanical stresses associated with large-scale operations, polyurethane screens can withstand it all. This robust nature allows these sieve plates to maintain their shape and performance over extended periods of use, ensuring a higher return on investment.

Furthermore, polyurethane sieve plates provide superior screening efficiency. Their high wear resistance allows them to maintain consistent performance, reducing the frequency of replacements. This is particularly important in industries such as mining, where downtime and maintenance can be costly and disruptive. With polyurethane sieve plates, you can ensure that your filtration processes run smoothly and efficiently with minimal interruption.

Why Urethane Screen Panels are the Ideal Choice for Filtration

Urethane screen panels are widely used in industries requiring high-performance filtration solutions. These panels are made from a specialized urethane material that combines flexibility and strength. This makes urethane screen panels highly resistant to damage from wear and tear, ensuring that they last longer than traditional screen materials.

One of the primary benefits of urethane screen panels is their ability to provide consistent and efficient material separation. Whether you're processing fine or coarse particles, urethane screen panels can deliver exceptional performance by filtering out unwanted materials while allowing the desired substances to pass through with ease. This ensures that your filtration system works at its peak efficiency, reducing energy costs and improving productivity.

In addition to their durability and performance, urethane screen panels are also highly customizable. They can be manufactured in a variety of shapes and sizes to meet the specific needs of your operation. This flexibility allows businesses to tailor their filtration systems to suit their exact requirements, making urethane screen panels a versatile and valuable solution for industries ranging from mining to wastewater treatment.

Moreover, urethane screen panels are designed to reduce the noise and vibration that can often be associated with traditional metal screens. This not only creates a quieter working environment but also reduces the wear and tear on other components of your filtration system. With urethane screen panels, you can improve the overall operational environment while boosting the performance of your filtration system.

The Role of Dewatering Screen Panels in Water Treatment

Dewatering screen panels are essential components in industries that deal with the separation of solids and liquids, particularly in wastewater treatment and mining. These panels are designed to efficiently remove excess water from materials such as sand, coal, and other aggregates. Dewatering screen panels are made from high-quality materials, such as polyurethane, which provide superior performance in terms of wear resistance and water drainage.

The primary function of dewatering screen panels is to reduce the moisture content of the materials being processed. This is achieved by using a high-frequency vibration mechanism that accelerates the draining process. As a result, materials are left with a drier, more manageable consistency, which is particularly important in applications where moisture content can affect the quality of the end product.

In wastewater treatment, dewatering screen panels help remove water from sludge, which is crucial for ensuring that the remaining solid waste is easier to handle and dispose of. The efficiency of dewatering screen panels ensures that the filtration process operates smoothly, with minimal downtime or interruptions. This not only improves the overall efficiency of the treatment process but also reduces operating costs by minimizing the need for additional processing steps.

In addition to their use in wastewater treatment, dewatering screen panels are also beneficial in mining and construction. They play a critical role in separating water from mined materials, ensuring that the extracted substances are dry and suitable for further processing or disposal. By efficiently dewatering materials, these panels help to streamline operations and improve the quality of the materials being processed.

The Importance of Dewatering Screens for Material Processing

Dewatering screens are a vital piece of equipment in material processing industries. These screens are specifically designed to remove excess water from granular or slurry materials, leaving behind dry, manageable solids. Dewatering screens are commonly used in industries such as mining, aggregate processing, and wastewater treatment to enhance the efficiency of material handling.

Dewatering screens are equipped with high-frequency vibrations that help to separate water from materials effectively. The screens are often paired with dewatering screen panels, which are designed to help accelerate the drainage process. Together, they form a highly effective system for improving the dewatering process, resulting in a more efficient operation.

The design of dewatering screens ensures that they can handle a variety of materials, including sand, coal, and other aggregates. By effectively removing excess water, dewatering screens help to improve the quality of the materials, ensuring that they are in the right condition for further processing or sale. This is particularly important in mining and aggregate processing, where the moisture content of the material can significantly impact its quality and usability.

Another advantage of dewatering screens is their ability to operate in harsh conditions. They are designed to withstand the rigors of industrial operations, including exposure to abrasive materials and harsh chemicals. With their high durability, dewatering screens can provide consistent performance, even in challenging environments, ensuring that your material processing operation runs smoothly and efficiently.

Urethane Screen Panels FAQs

What is the primary advantage of polyurethane sieve plates?

Polyurethane sieve plates offer exceptional durability and wear resistance, making them ideal for industries that deal with abrasive materials. They also improve filtration efficiency, reducing the need for maintenance and downtime.

How do urethane screen panels improve filtration?

Urethane screen panels provide consistent material separation, ensuring that fine and coarse particles are efficiently filtered. Their durability and customization options also make them a versatile choice for various industries.

What is the role of dewatering screen panels?

Dewatering screen panels are used to remove excess water from materials such as sand, coal, and sludge, improving the consistency of the materials and making them easier to handle or dispose of.

How do dewatering screens enhance material processing?

Dewatering screens efficiently separate water from granular materials, improving the quality of the end product. They also help streamline operations by reducing the need for additional processing steps.

Can dewatering screens handle different types of materials?---H3

Yes, dewatering screens are designed to handle a variety of materials, including sand, coal, and aggregates, making them versatile and suitable for a range of industries, including mining and wastewater treatment.