In the ever-evolving industrial world, efficient separation and filtration are critical processes across various sectors, from mining to food processing. Screen sieve technology has become an integral part of these industries due to its high efficiency in sorting and sifting materials. A screen sieve is a tool that uses a mesh or perforated surface to separate materials based on their size. It is used to filter fine particles from larger materials, which is crucial in industries such as mining, pharmaceuticals, agriculture, and even in the production of food products.

The role of a screen sieve extends far beyond just simple filtration. It is designed to enhance productivity by streamlining processes, ensuring that only the desired material is passed through for further treatment. In mining, for example, a screen sieve is often used to separate ore particles based on size, which helps in ensuring that the appropriate minerals are processed. Similarly, in the food industry, it helps separate solid and liquid components, which improves the quality of the final product. This versatility is one of the reasons why screen sieves have become indispensable in various sectors.

Moreover, screen sieves are designed to handle heavy-duty operations, making them suitable for both large-scale industrial applications and small operations that require precision. Their durability, ease of maintenance, and cost-effectiveness make them an excellent investment for businesses looking to improve operational efficiency. Whether you are looking for a simple sifting solution or a complex industrial application, screen sieves offer reliable, high-quality performance.

The Advantages of Industrial Sieves and Screens in Manufacturing Processes

In manufacturing, especially in industries dealing with raw materials or chemicals, having the right equipment for sorting and sieving is vital. Industrial sieves and screens are designed for high-capacity separation, ensuring that materials are filtered with accuracy and speed. These industrial tools are robust and durable, capable of handling large quantities of material and separating them efficiently.

The importance of industrial sieves and screens lies in their ability to provide fine-tuned sorting. For example, in the pharmaceutical industry, it is essential to separate particles accurately to ensure consistency in medicine production. Industrial sieves and screens are capable of sorting particles according to strict specifications, ensuring that only the correct size is used in final products. Similarly, industries such as food processing rely on sieves to remove unwanted particles from grains, flours, and other bulk materials.

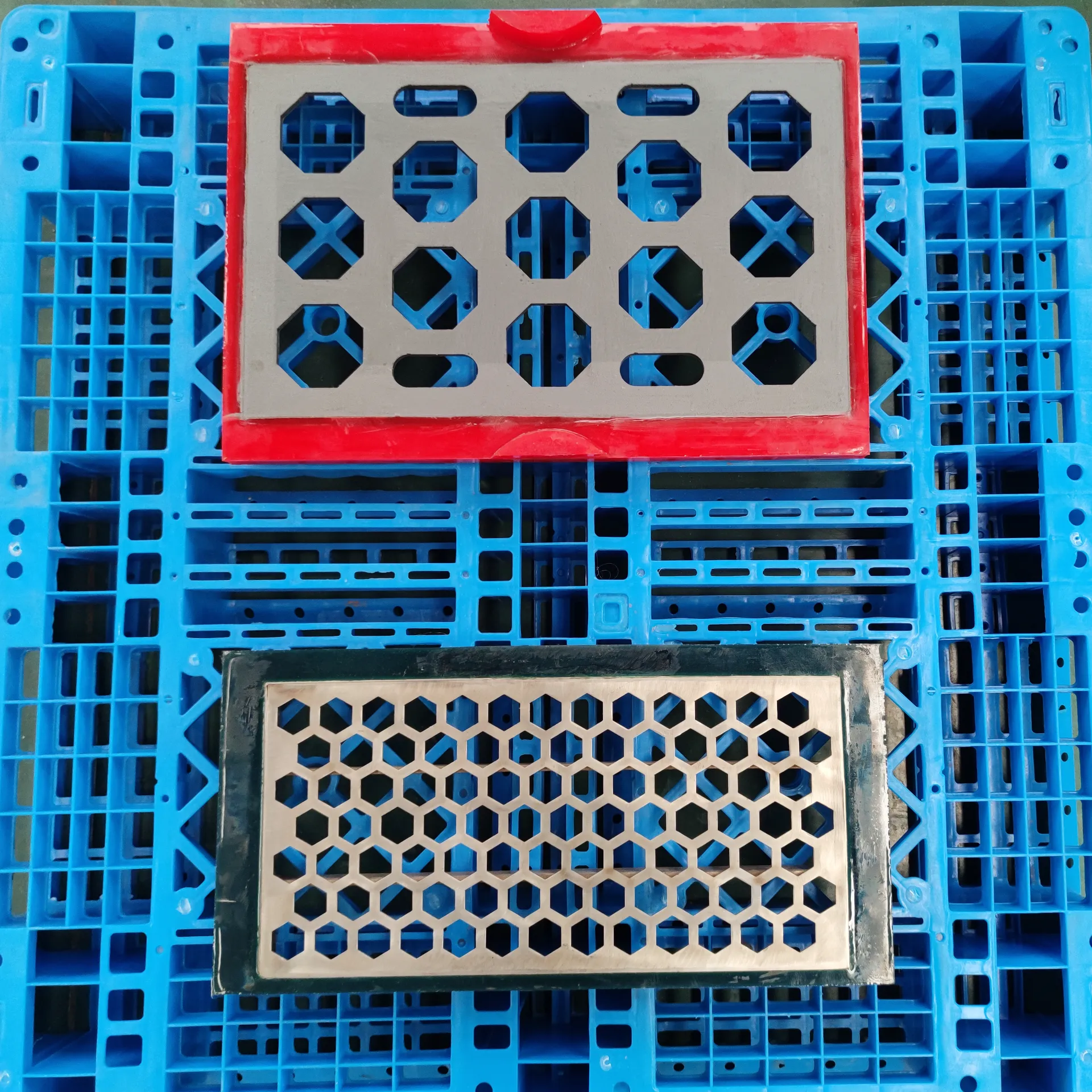

Another advantage of industrial sieves and screens is their versatility. They come in various mesh sizes, materials, and designs, meaning they can be tailored to meet the needs of specific industries. Whether you're processing chemicals, minerals, or foodstuffs, there's a sieve or screen that can suit your requirements. The ability to customize these tools allows businesses to enhance their operational efficiency and reduce material waste, which ultimately leads to increased profitability.

Furthermore, industrial sieves and screens are designed to be user-friendly. Their simple operation and easy maintenance reduce downtime and ensure consistent, high-quality results. The durability of these sieves means they can handle rigorous work environments, giving businesses peace of mind knowing their equipment can perform under pressure.

How Vibrating Screen Sieve Improves Efficiency in Material Processing

Vibrating screen sieve technology has revolutionized the way materials are sorted and processed in various industries. This innovation uses vibration to move materials across the screen surface, which allows for more effective separation based on particle size. The key advantage of a vibrating screen sieve is its ability to handle large volumes of materials and sort them quickly and accurately.

The use of a vibrating screen sieve is especially valuable in industries such as mining, agriculture, and construction, where bulk materials need to be sifted and classified. In the mining industry, for example, a vibrating screen sieve is used to separate minerals based on size, allowing for more efficient extraction of valuable materials. Similarly, in agriculture, it can be used to separate grains from unwanted debris, improving product quality and reducing wastage.

What sets vibrating screen sieves apart from traditional sieves is their ability to provide continuous, high-frequency vibration. This motion helps to break up clumps, prevent clogging, and increase throughput. As a result, businesses can process larger volumes of material in less time, leading to improved productivity and cost savings.

Moreover, vibrating screen sieves are designed to be adaptable, offering a variety of configurations and mesh sizes to meet the specific needs of different applications. This customization allows businesses to optimize their sorting processes, whether they are separating fine particles or larger aggregates. The efficiency, versatility, and scalability of vibrating screen sieves make them a valuable tool for any material processing operation.

Choosing the Right Screen Sieve for Your Industrial Needs

When selecting the right screen sieve for your industrial needs, it is important to consider several factors that can impact performance. The material being processed, the desired separation size, and the volume of material are all key considerations when making a decision.

For example, industries that process fine powders, such as pharmaceuticals or food manufacturing, will require a screen sieve with a finer mesh to separate smaller particles effectively. Conversely, industries dealing with larger materials, such as mining, will need sieves with coarser mesh sizes to separate larger particles. Understanding the nature of the material and the type of separation needed is essential for selecting the right sieve.

The durability and construction material of the screen sieve are also important factors to consider. Sieves used in high-wear environments, such as mining, will need to be made from high-strength materials like stainless steel to withstand abrasion. For lighter industrial applications, more affordable materials like aluminum may be sufficient. Choosing the right material ensures that the sieve can handle the demands of the specific application, reducing downtime and maintenance costs.

Additionally, the efficiency of the sieve is a critical factor in choosing the right one for your business. A high-performance screen sieve can help increase throughput, reduce material waste, and improve overall productivity. Investing in a high-quality sieve will ultimately save time and money in the long run, making it a wise choice for businesses looking to enhance their operations.

Screen Sieve FAQs

What is a screen sieve used for?

A screen sieve is used to separate materials based on size. It helps filter out unwanted particles from the desired material, improving the efficiency of industrial processes.

What are the benefits of industrial sieves and screens?

Industrial sieves and screens improve the efficiency and accuracy of sorting materials in large-scale industrial applications. They help reduce waste, improve product quality, and increase overall productivity.

How does a vibrating screen sieve work?

A vibrating screen sieve uses high-frequency vibration to move materials across the screen surface, separating them based on their size. This ensures efficient sorting and prevents clogging.

How do I choose the right screen sieve for my needs?

The right screen sieve depends on factors such as the material being processed, the desired separation size, and the volume of material. Consider these factors to select a sieve that suits your industrial needs.

Can vibrating screen sieves handle large volumes of material?

Yes, vibrating screen sieves are designed to handle large volumes of material, making them ideal for industries like mining and construction where bulk sorting is required.