PU mesh is rapidly becoming the preferred choice in various industries for its durability, reliability, and efficiency in dry screening. Whether you're dealing with sand, gravel, or mining products, PU mesh plays a crucial role in improving productivity by ensuring high-quality separation and reducing operational downtime. This article will explore the benefits of PU mesh, PU screen mesh, and how dry screening can optimize your processes.

Why Choose PU Mesh for Your Screening Needs?

When searching for durable and efficient screening solutions, PU mesh offers several advantages that make it the go-to material for numerous industries. Unlike traditional screen materials, PU mesh provides greater flexibility, resistance to wear, and an extended lifespan. One of the key reasons why PU mesh is favored in various industries is its ability to handle harsh materials with ease, such as sand, gravel, coal, and mineral processing products.

The durability of PU mesh ensures that it can withstand abrasive materials, reducing the frequency of replacements and maintenance costs. This is a significant advantage for industries such as mining, aggregates, and recycling, where screening equipment often faces tough operating conditions. Additionally, PU mesh is resistant to impact, corrosion, and UV degradation, making it ideal for outdoor applications where exposure to the elements can wear down other types of screening media.

With its superior wear resistance and long service life, PU mesh reduces downtime and increases operational efficiency. Its high abrasion resistance ensures that it continues to perform at optimal levels even under intense conditions, providing a more reliable and cost-effective solution for your screening needs.

The Versatility of PU Screen Mesh

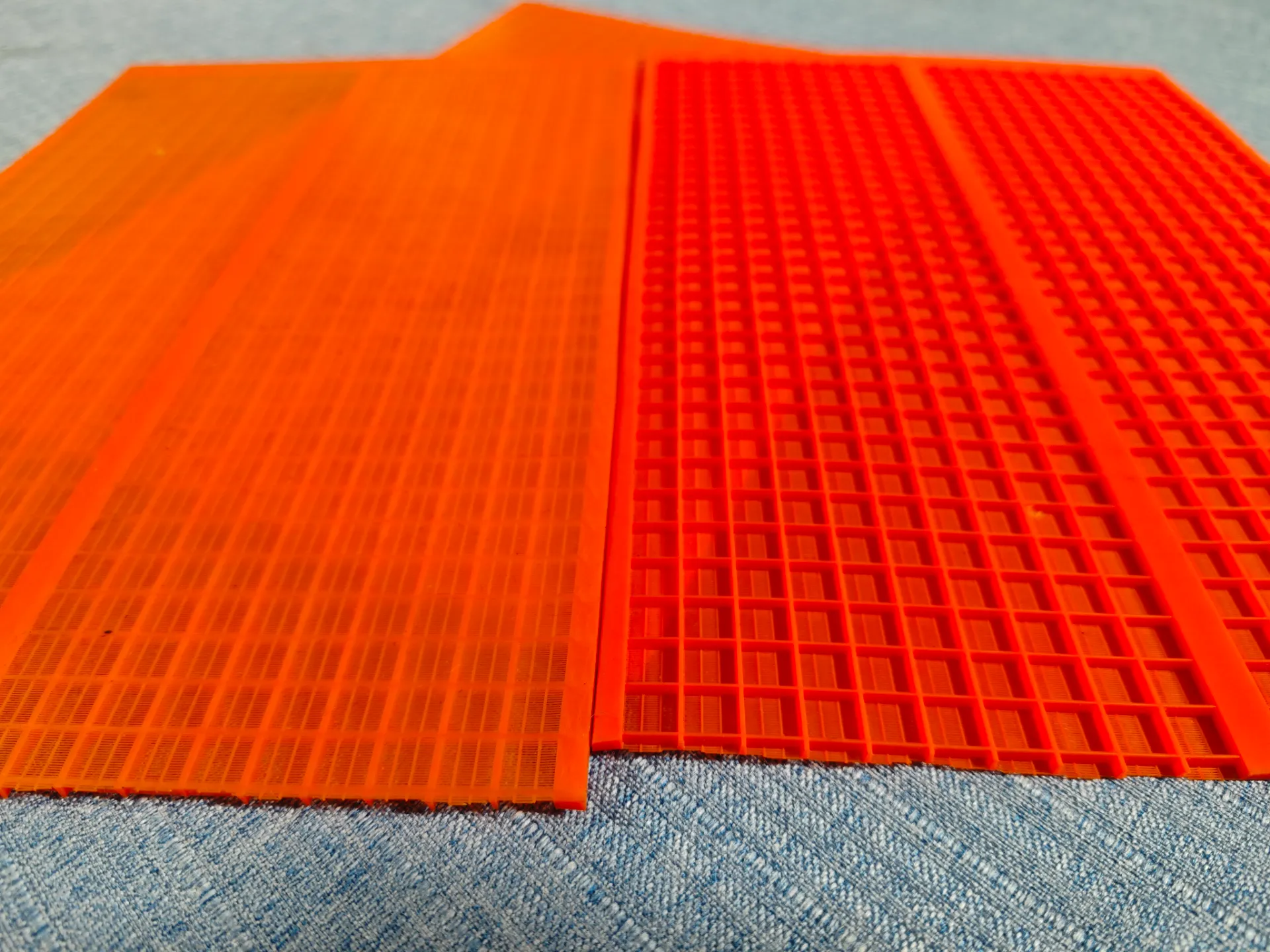

PU screen mesh is a flexible and versatile solution used in a wide range of applications, from dry screening to wet processing. Unlike traditional woven wire mesh, PU screen mesh provides superior flexibility and strength, making it ideal for various types of materials, including those that are difficult to screen with conventional materials.

The flexibility of PU screen mesh allows it to be customized for different types of applications, whether it's for dry screening of granular materials or for use in fine or coarse applications. PU screen mesh can also be produced in various configurations, such as square, rectangular, or even customized apertures to meet the specific requirements of different screening processes.

One of the most significant advantages of PU screen mesh is its ability to handle materials in harsh conditions. Whether you're screening wet or dry materials, PU screen mesh can maintain its structural integrity, ensuring that it continues to perform effectively even when exposed to high impact, moisture, or chemicals. This makes PU screen mesh a reliable choice for industries such as mining, construction, and recycling, where screening materials can be abrasive or aggressive.

Streamlining Operations with Dry Screening

In many industries, dry screening plays a vital role in sorting and classifying materials without the use of water or chemicals. Dry screening is particularly beneficial for materials like sand, aggregates, coal, and minerals, as it helps improve the efficiency and quality of the separation process. With PU mesh or PU screen mesh, dry screening becomes even more effective, allowing for faster, more accurate results.

One of the major benefits of dry screening is that it reduces the need for water and chemicals, making the process more environmentally friendly and cost-effective. This is especially important for industries that deal with large volumes of material, where water usage and disposal can become costly and challenging. By utilizing PU mesh or PU screen mesh in dry screening, you can maximize the efficiency of your operations while reducing your environmental impact.

In addition, dry screening can help improve the overall quality of the materials being processed. Since there is no water to dilute or affect the quality of the material, the separation process is more precise, resulting in higher-grade materials that can be sold or used in other applications. Whether you're working with aggregates, coal, or other minerals, dry screening with PU mesh or PU screen mesh offers an effective way to separate materials with precision.

Enhancing Screening Efficiency with PU Mesh in Dry Screening

The combination of PU mesh and dry screening brings significant improvements to screening efficiency. Traditional screening methods often struggle with the separation of fine particles, especially when dealing with sticky or damp materials. PU mesh, however, is engineered to handle such challenges with ease, offering consistent performance even under demanding conditions.

PU mesh helps enhance screening efficiency by providing a high level of flexibility, durability, and wear resistance. It ensures that materials flow freely through the screen, reducing the likelihood of blockages and ensuring that the separation process remains efficient throughout the operation. This is particularly important in industries like mining, where continuous, smooth operation is essential for maintaining productivity and profitability.

Moreover, PU mesh's ability to handle dry materials with ease makes it ideal for applications such as sand and gravel processing, as well as coal and ore screening. With its high abrasion resistance, PU mesh ensures that your screening equipment performs at its best, minimizing downtime and reducing the need for frequent replacements. This allows businesses to save on maintenance costs and improve overall operational efficiency.

PU Mesh FAQs

What is the difference between PU mesh and traditional screen materials?

PU mesh offers superior durability and flexibility compared to traditional screen materials like wire mesh, making it more suitable for handling abrasive, wet, or sticky materials.

Can PU screen mesh be used for both dry and wet screening?

Yes, PU screen mesh is versatile and can be used effectively in both dry and wet screening applications, offering reliable performance under various conditions.

How does dry screening improve material separation?

Dry screening helps separate materials without the use of water or chemicals, resulting in more precise separation and higher-quality materials.

Why is PU mesh ideal for dry screening?

PU mesh provides excellent abrasion resistance and flexibility, making it perfect for dry screening applications where materials can be coarse, sticky, or difficult to process.

Can PU mesh improve the lifespan of screening equipment?

Yes, PU mesh significantly improves the lifespan of screening equipment by reducing wear and tear, leading to less frequent replacements and lower maintenance costs.