In industrial filtration systems, the quality and performance of the screen element are crucial for operational success. The wedge wire screen has emerged as the gold standard for industries ranging from water treatment to petrochemical processing. Designed for durability, precision, and ease of maintenance, the wedge wire screen is transforming how businesses approach filtration solutions. Whether you are sourcing a wedge wire screen for sale or evaluating the best wedge wire manufacturers, understanding its unique advantages will help you make the right choice for your applications.

Differences Between Wedge Wire Screen and Traditional Screen Tubes

Traditional screen tubes, often made from perforated plates or woven mesh, have long been used in filtration. However, when compared to a wedge wire screen, the gap in performance and longevity is clear. The wedge wire screen features a V-shaped profile that allows only two contact points with debris, dramatically reducing clogging compared to flat or woven screens.

This innovative design ensures uninterrupted flow rates and superior mechanical strength. Unlike traditional screens, v wire screen products do not easily deform under pressure, offering enhanced durability even under harsh operating conditions. When exploring a wedge wire screen for sale, it's crucial to recognize that these screens provide far greater open area percentages, boosting efficiency while minimizing energy consumption.

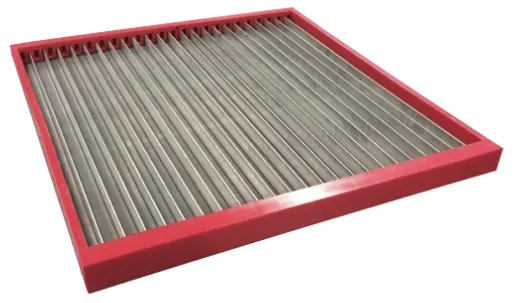

Furthermore, top wedge wire manufacturers engineer their screens to be fully customizable. From cylinder shapes to flat panels and baskets, the flexibility of the wedge wire screen ensures it can be tailored precisely to the demands of your industry—something traditional screens simply cannot match.

Filtration Accuracy of Wedge Wire Screen: Setting the Standard

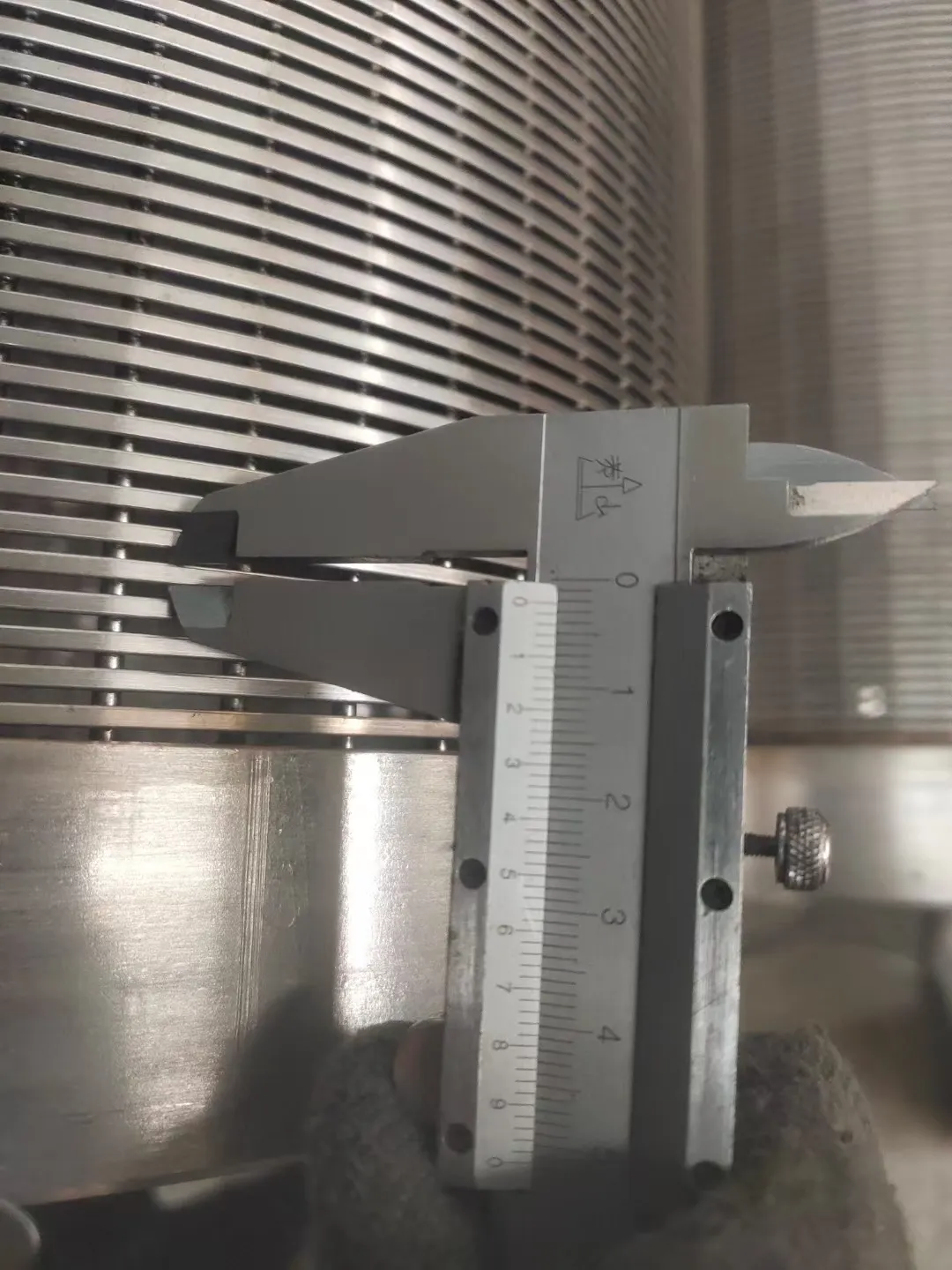

Filtration accuracy is a critical specification, and this is where the wedge wire screen truly shines. Thanks to its precise construction, a v wire screen can achieve filtration ratings as fine as 25 microns or even finer, depending on application needs. Each wire and supporting rod are individually welded to ensure consistent slot openings across the entire screen surface.

When searching for a wedge wire screen for sale, customers are often amazed at how the accuracy of slot openings can directly impact operational reliability. High-precision slots ensure that only particles of a specific size are allowed through, protecting downstream equipment and maintaining process integrity.

Even better, the wedge wire screen price remains competitive despite its superior construction. Many leading wedge wire manufacturers offer a wide range of customizable slot sizes, ensuring that clients can achieve the perfect balance of flow rate, strength, and particle retention without breaking the budget.

How to Choose the Opening Width of a Wedge Wire Screen

Choosing the right opening width for your wedge wire screen is essential for maximizing performance. If the slots are too large, unwanted debris can pass through and damage downstream processes. If too small, clogging and reduced flow rates can result.

Leading wedge wire manufacturers recommend starting with a clear understanding of the particle size distribution of your feed material. For example, in water treatment applications where fine particulate removal is critical, narrower slot widths are preferable. In contrast, industrial or mining applications often demand wider slots to handle higher solids loads without clogging.

When reviewing a wedge wire screen for sale, consulting directly with manufacturers ensures the opening width is perfectly matched to your needs. Furthermore, the consistent, smooth edges of a v wire screen contribute to superior flow dynamics, reducing the energy costs associated with pumping and filtration.

Considering the highly customizable nature of the product, and the excellent wedge wire screen price options available today, it has never been easier to optimize your filtration setup with a precisely engineered wedge wire screen.

Durability and Cost-Effectiveness of Wedge Wire Screens

One of the biggest advantages of choosing a wedge wire screen is its exceptional durability. Made from high-grade stainless steel or special alloys, these screens offer outstanding resistance to corrosion, chemical attack, and physical wear. This resilience translates into significantly longer service life compared to traditional mesh or perforated screens.

Despite the high-quality materials and precision welding, the wedge wire screen price remains very reasonable, especially when considering the savings on maintenance, replacement, and downtime. When purchasing from reputable wedge wire manufacturers, customers gain not only superior products but also technical support for installation, slot selection, and maintenance best practices.

Investing in a v wire screen means fewer operational interruptions and lower total cost of ownership over the life of your equipment. With a growing number of industries shifting to wedge wire screen for sale options over traditional solutions, it is clear that this technology is setting the benchmark for modern filtration systems.

Wedge Wire Screen FAQs

What makes wedge wire screens superior to traditional filtration screens?

The V-shaped profile of the wedge wire screen minimizes clogging, provides greater open area, and ensures superior mechanical strength compared to traditional woven or perforated screens.

How fine can the filtration accuracy of a wedge wire screen be?

A v wire screen can achieve filtration accuracies as fine as 25 microns, with precision slot sizes consistently maintained across the entire screen surface.

How do I select the correct slot opening width for my application?

Selection depends on your required filtration particle size and flow rate. Top wedge wire manufacturers often provide detailed consultation services to help choose the perfect slot size.

Are wedge wire screens cost-effective over the long term?

Yes, while the wedge wire screen price might be slightly higher initially compared to traditional screens, their long service life and reduced maintenance costs make them far more economical overall.

What industries most commonly use wedge wire screens?

Industries such as water treatment, mining, food processing, oil and gas, and pulp and paper industries widely use wedge wire screens because of their strength, precision, and durability.