Industrial filtration is a critical process in many industries, including mining, wastewater treatment, and food processing. The need for effective separation systems has led to the development of specialized screens like DSM screens, which have proven their efficiency in filtering out unwanted particles. DSM screens are designed to handle high volumes of material and provide precise separation, making them a reliable choice for a variety of industrial applications.

One of the key features of DSM screens is their ability to offer consistent and high-performance separation in environments that require durability and strength. These screens are made from robust materials such as stainless steel, which ensures they can withstand the harsh conditions often found in industrial settings. DSM screens are particularly useful in wastewater treatment plants where the removal of solids is crucial for maintaining water quality. They are also employed in mining, where they help separate ores and minerals based on size, improving the efficiency of material processing.

The versatility of DSM screens is another reason they are so widely used. Whether you are processing solid waste, treating water, or separating minerals, these screens can be customized to suit the needs of different applications. The reliable performance of DSM screens helps reduce downtime and maintenance costs, which is a significant advantage in industries where continuous operation is essential. With their durable construction and exceptional filtering capabilities, DSM screens are an investment that businesses can rely on for years to come.

The Advantages of Wedge Wire DSM Screens in Industrial Filtration

Wedge wire DSM screens are an enhanced version of traditional screens, offering several advantages that make them ideal for specific industrial applications. These screens are designed with a unique wedge-shaped profile that provides a larger open area for filtration, allowing for more efficient separation of solids from liquids. The wedge wire design ensures that the screen can filter particles of various sizes while minimizing the risk of clogging, which is a common issue with standard screens.

One of the main benefits of wedge wire DSM screens is their ability to handle high flow rates while maintaining effective filtration. The design allows for better distribution of materials across the screen surface, preventing blockages and enhancing the overall performance of the system. This is particularly important in industries like mining and wastewater treatment, where large volumes of material need to be processed quickly and efficiently.

Another advantage of wedge wire DSM screens is their durability. These screens are made from high-quality materials such as stainless steel, which ensures that they can withstand abrasive environments and harsh chemicals. This makes them ideal for industries where the conditions are tough, and the equipment must be able to endure wear and tear without losing its performance.

The versatility of wedge wire DSM screens also cannot be overlooked. They are available in a range of sizes and designs, allowing businesses to choose the screen that best suits their specific needs. Whether you are looking for a screen to process wastewater, separate materials in the mining industry, or filter food products, wedge wire DSM screens can be tailored to meet your requirements, ensuring optimal performance in any setting.

How Sieve Bend Screens Enhance Material Separation Efficiency

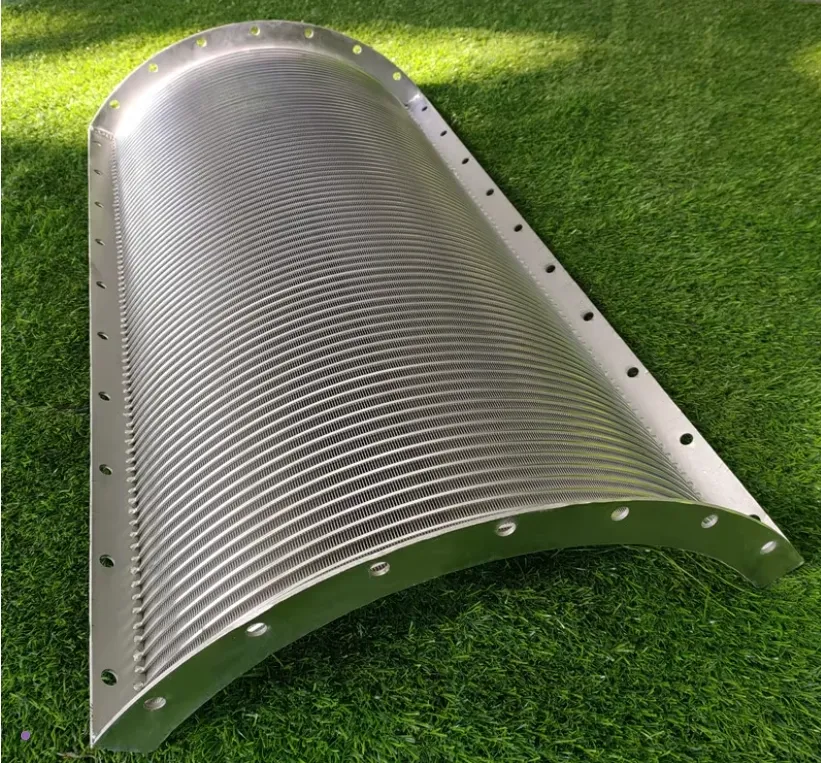

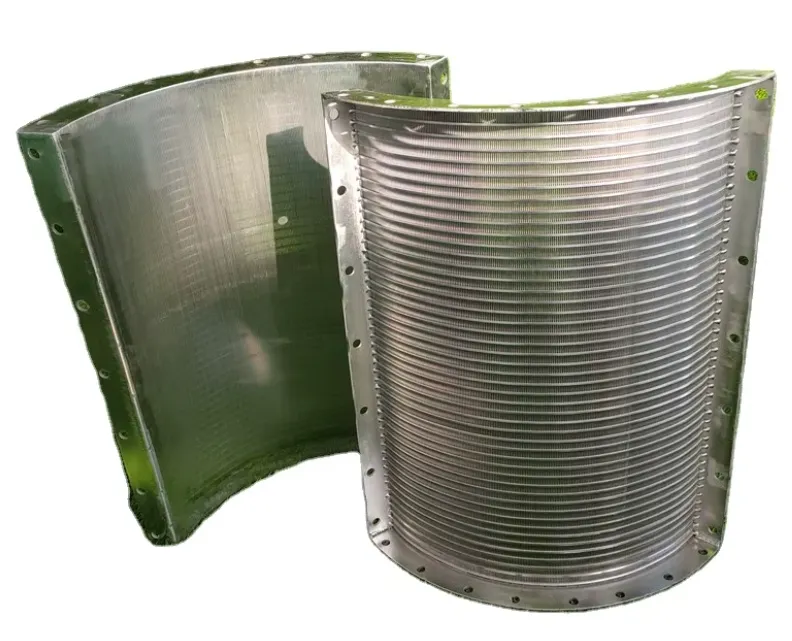

Sieve bend screens are another innovative filtration technology that has gained popularity in industrial filtration processes. These screens are curved in shape, which allows for more effective separation of materials compared to traditional flat screens. The curvature of the screen increases the contact area between the material and the screen surface, improving the overall filtration process.

One of the main advantages of sieve bend screens is their ability to handle high flow rates while maintaining effective separation. The curved shape enables gravity-assisted filtration, allowing liquids to pass through while retaining larger particles. This design makes sieve bend screens particularly effective in applications such as wastewater treatment, where large volumes of liquid need to be processed quickly.

In addition to their efficiency, sieve bend screens are known for their ability to reduce clogging. The curved design helps prevent material from accumulating on the surface, which can cause blockages in traditional flat screens. This results in lower maintenance requirements and longer-lasting performance, making sieve bend screens a cost-effective choice for industries with high-volume filtration needs.

Another key benefit of sieve bend screens is their versatility. They are available in various sizes and configurations to meet the specific needs of different industries. Whether you are working with mining materials, processing food products, or treating wastewater, sieve bend screens can be customized to suit your filtration requirements, providing optimal performance and efficiency.

Choosing the Right Filtration System: DSM Screens vs. Sieve Bend Screens

When it comes to choosing the right filtration system for your industrial needs, it’s important to understand the differences between DSM screens and sieve bend screens. Both types of screens offer excellent filtration capabilities, but each has its own advantages depending on the application.

DSM screens are ideal for industries where high-efficiency filtration is required in harsh conditions. These screens are designed to handle large volumes of material and can provide consistent performance over time. They are often used in wastewater treatment plants and mining operations where continuous operation and durability are key. The ability of DSM screens to filter materials based on size and provide high flow rates makes them a versatile option for a variety of industries.

On the other hand, sieve bend screens are particularly effective in applications that require gravity-assisted filtration. The curved design of these screens allows for more effective separation of materials and reduces the risk of clogging. Sieve bend screens are especially useful in high-volume liquid filtration processes, such as wastewater treatment, where large volumes of liquid need to be processed quickly and efficiently.

When deciding between DSM screens and sieve bend screens, it’s important to consider the specific needs of your industry. If you require high flow rates and need a screen that can handle tough conditions, DSM screens are an excellent choice. However, if you need a filtration system that can efficiently handle liquids and reduce clogging, sieve bend screens may be the better option.

DSM Screens FAQs

What are DSM screens used for?

DSM screens are used for industrial filtration processes, such as wastewater treatment, mining, and food processing. They efficiently separate solids from liquids based on particle size.

What is the advantage of wedge wire DSM screens?

Wedge wire DSM screens provide better filtration efficiency and durability compared to traditional screens. Their wedge-shaped design allows for higher flow rates and reduces clogging.

How do sieve bend screens work?

Sieve bend screens use a curved design that allows gravity-assisted filtration. This shape increases the surface area for material contact, improving the separation of solids from liquids.

Can DSM screens handle high flow rates?

Yes, DSM screens are designed to handle high flow rates while maintaining effective filtration, making them ideal for applications in mining, wastewater treatment, and more.

Are sieve bend screens suitable for all industries?

Sieve bend screens are highly versatile and can be used in industries such as mining, wastewater treatment, and food processing. Their curved design makes them particularly effective in liquid filtration processes.