In the world of industrial filtration and separation processes, polyurethane screens and banana screens have become indispensable tools. These screening solutions are engineered to meet the rigorous demands of industries that rely on high-performance and durable screening systems. From mining and aggregates to food processing and wastewater treatment, the need for efficient and reliable screening is universal. The screening deck and dewatering vibrating screen systems complement these solutions, enhancing their effectiveness and offering greater versatility for industrial applications.

This advertrial will dive deep into the role and benefits of polyurethane screens, banana screens, screening decks, and dewatering vibrating screens, and how they serve to elevate productivity and operational efficiency in a variety of industries. These screening technologies are transforming how materials are separated, sorted, and processed, ensuring quality and reducing operational costs in the long run.

The Durability and Efficiency of Polyurethane Screens

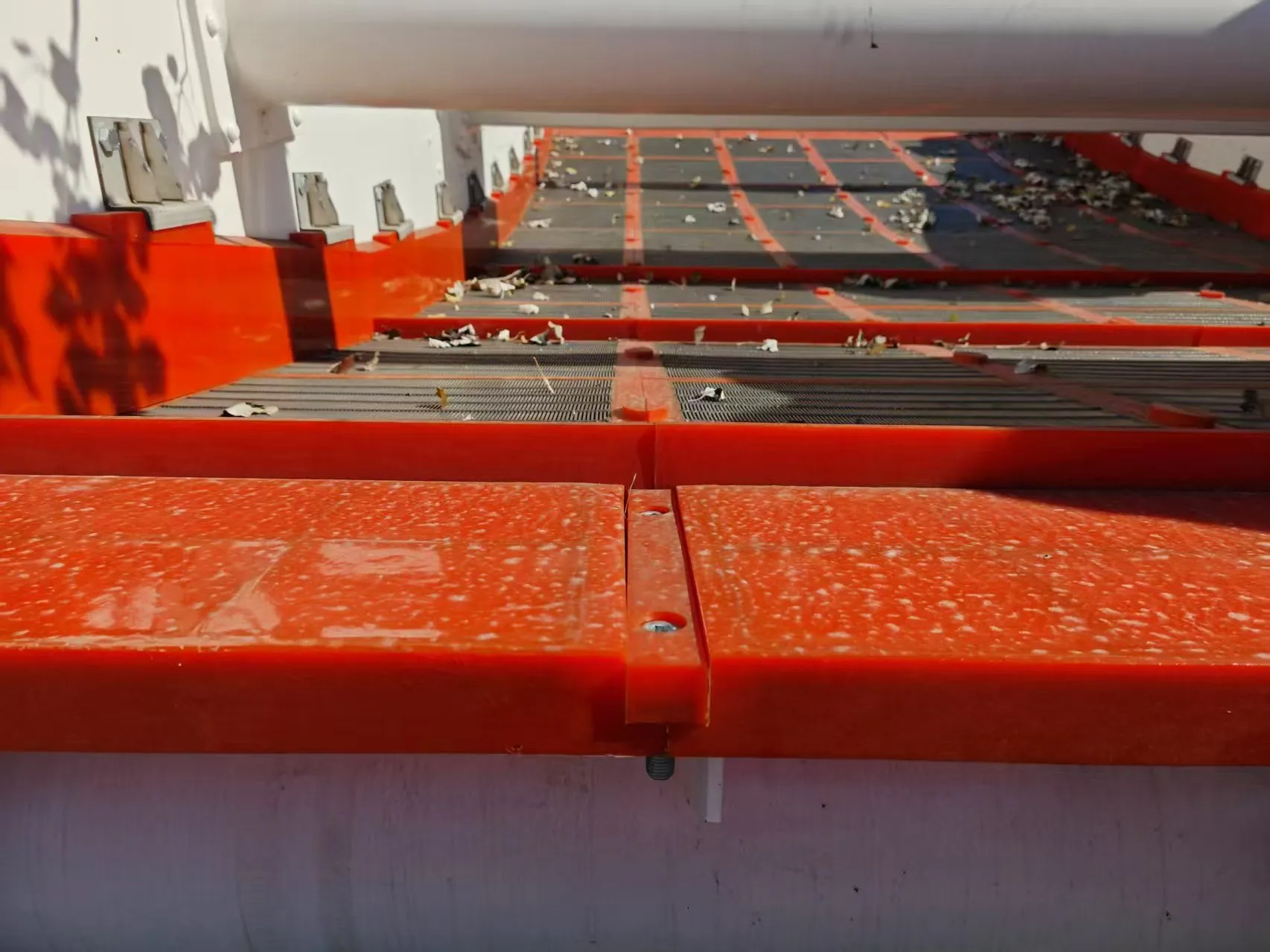

Polyurethane screens are one of the most effective and long-lasting screening solutions available today. Manufactured from high-quality polyurethane materials, these screens provide exceptional wear resistance, making them ideal for industries that deal with abrasive materials. Polyurethane screens are particularly useful in mining, aggregate, and recycling applications, where they endure heavy-duty use and exposure to harsh environments.

What sets polyurethane screens apart from other types of screening media is their ability to perform well under extreme conditions. They have higher tensile strength and are more flexible compared to traditional metal screens. This flexibility allows them to withstand impact and vibrations without cracking or breaking, ensuring longer life and reducing the frequency of replacements.

Additionally, polyurethane screens are known for their self-cleaning properties, which is crucial in minimizing downtime and maximizing operational efficiency. The material’s ability to prevent clogging and maintain a consistent flow makes it ideal for industries where high productivity is required. Whether dealing with wet or dry materials, polyurethane screens deliver superior results in material sorting and separation processes.

The versatility of polyurethane screens makes them suitable for a range of screening processes, including fine and coarse material separation. Whether you need to screen aggregates, sand, minerals, or even food products, polyurethane screens can be customized to meet the specific needs of the application, providing a tailored solution that improves the efficiency of your operations.

Understanding the Role of Banana Screens in Screening Applications

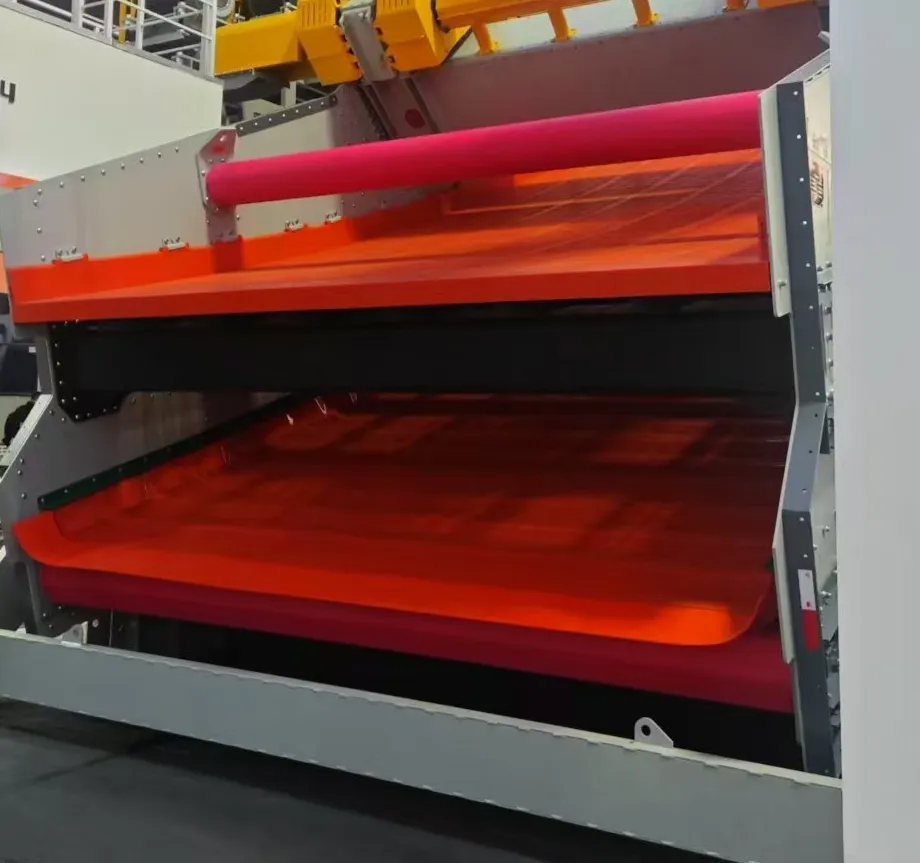

Banana screens are widely recognized for their ability to handle large volumes of material in a compact and efficient manner. These screens are specifically designed to optimize the screening process in industries that require high throughput, such as mining, aggregates, and recycling. The unique design of banana screens features multiple sloped sections, which create a "banana-shaped" deck. This innovative design allows for improved material flow and ensures that particles are efficiently separated over the entire screen surface.

The banana screen is designed to handle varying material sizes, from fine particles to larger lumps, ensuring that each size fraction is effectively separated. This makes banana screens ideal for applications where material must be sorted quickly and efficiently. Additionally, the multi-deck configuration allows for greater screening capacity within a smaller footprint, making them a space-saving solution for high-volume processes.

One of the key benefits of banana screens is their ability to improve screening efficiency while reducing energy consumption. The unique deck design reduces the amount of energy needed to move material through the screen, leading to lower operational costs. The increased efficiency, combined with the ability to handle large volumes, makes banana screens an essential tool in any industry that requires high-performance screening.

Another advantage of banana screens is their ability to handle wet and dry materials with equal ease. Whether you're screening coal, sand, gravel, or minerals, banana screens provide reliable performance and high throughput. This versatility is one of the main reasons why these screens are so widely used in industries like mining, construction, and recycling.

Enhancing Screening Operations with the Screening Deck

The screening deck is an integral component of any screening system, providing the platform on which materials are separated and sorted. It plays a crucial role in maximizing the efficiency of the entire screening process by ensuring that the material is evenly distributed across the screen surface. A well-designed screening deck ensures optimal flow and improves the accuracy of particle separation.

A screening deck can be customized to accommodate different types of screening media, including polyurethane screens and banana screens. The deck supports the screens and enables them to perform at their best by allowing for easy installation, maintenance, and adjustment. The configuration of the screening deck can also influence the performance of the screening system, as it dictates how the material flows and interacts with the screen.

In some cases, the screening deck may feature adjustable angles, allowing for better control over material flow and separation efficiency. This flexibility ensures that industries can adapt their screening processes to meet the demands of different materials and operational conditions. Whether used in mining, recycling, or aggregate processing, the screening deck plays a vital role in the overall success of the screening system.

The addition of a high-quality screening deck to your screening system enhances material throughput and reduces maintenance costs. By ensuring that the material is evenly distributed and flows efficiently through the screening system, the screening deck helps maximize productivity and minimize the likelihood of operational interruptions.

The Effectiveness of the Dewatering Vibrating Screen in Moisture Control

A dewatering vibrating screen is a specialized screening system used to remove excess moisture from materials, making it ideal for industries that need to process wet materials. These screens are commonly used in the mining, aggregate, and construction industries to separate fine particles from liquids and reduce the water content of materials.

The dewatering vibrating screen operates by applying vibration to the material, which helps to accelerate the removal of water. As the material moves across the screen, the excess moisture drains through the mesh, leaving behind drier, more manageable particles. This process helps improve the quality and consistency of the material, making it easier to handle and transport.

One of the primary advantages of dewatering vibrating screens is their ability to handle high moisture content in materials without compromising the separation efficiency. These screens are designed to cope with the added weight and resistance of wet materials, ensuring that the separation process remains efficient even under challenging conditions. The result is cleaner, drier material that is easier to process, store, and transport.

The dewatering vibrating screen also reduces the need for additional drying or dewatering processes, saving both time and energy. This makes it an essential tool for industries that rely on processing wet materials, such as coal preparation, mineral processing, and wastewater treatment.

Polyurethane Screens FAQs

What are Polyurethane screens used for?

Polyurethane screens are used for efficient separation and sorting of materials in industries such as mining, aggregate processing, and food production. They are durable, flexible, and provide high wear resistance.

How do banana screens improve screening efficiency?

Banana screens feature a multi-sloped design that improves material flow and increases throughput. This makes them ideal for handling large volumes of material with varying particle sizes.

What role does a screening deck play in the screening process?

A screening deck supports the screening media and ensures optimal material distribution across the screen surface, improving the accuracy and efficiency of particle separation.

How does a dewatering vibrating screen work?

A dewatering vibrating screen uses vibration to separate excess moisture from materials, making it ideal for processing wet materials in industries like mining, aggregate processing, and wastewater treatment.

Why should industries choose polyurethane screens and banana screens?

Both polyurethane screens and banana screens offer durability, high throughput, and efficiency, making them suitable for industries that require reliable separation of materials in demanding conditions.