In industrial settings where continuous filtration is required, the challenge of keeping screens clear of blockages is a persistent one. Fortunately, technological advancements have led to the development of self cleaning screens and self cleaning screen mesh, which offer a solution that enhances operational efficiency and minimizes downtime. These innovative screening solutions are revolutionizing how industries approach material separation, allowing for more reliable and effective operations.

Whether you're in wastewater treatment, mining, or agriculture, self cleaning screens can significantly improve the performance of your filtration system. Their ability to clean themselves during operation eliminates the need for constant maintenance, ensuring that your filtration process remains uninterrupted. In this article, we’ll explore the many advantages of self cleaning screens and self cleaning screen mesh, how they function, and why they are becoming indispensable in various industries.

The Advantages of Self Cleaning Screens in Industrial Applications

Self cleaning screens are designed to maintain high operational efficiency by preventing clogging during the screening process. One of the biggest challenges in many industrial applications is the buildup of materials on the screen, which can block the passage of liquids or solids and reduce the screen's performance. Self cleaning screens address this problem by using automated cleaning mechanisms that ensure the screen remains clear, even during operation.

The main advantage of self cleaning screens is their ability to operate continuously without the need for manual cleaning or frequent downtime. Traditional screens often require periodic cleaning to remove blockages, which can result in costly production delays. With self cleaning screens, you can avoid this issue, saving both time and money. This is especially beneficial in industries where uptime is critical, such as wastewater treatment plants, food processing facilities, and mining operations.

Moreover, self cleaning screens are highly durable and designed to handle a wide range of materials. They are particularly effective in applications where materials with varying particle sizes are being processed. Whether it's fine particles in wastewater or coarse materials in mining, self cleaning screens can provide consistent and reliable performance without the need for frequent adjustments or repairs.

Another important benefit is their cost-effectiveness. While self cleaning screens may have a higher initial cost compared to traditional screens, the reduction in maintenance and downtime results in a lower overall cost of ownership. This makes them a smart investment for industries looking to improve productivity and reduce operational costs over the long term.

How Self Cleaning Screen Mesh Enhances Filtration Performance

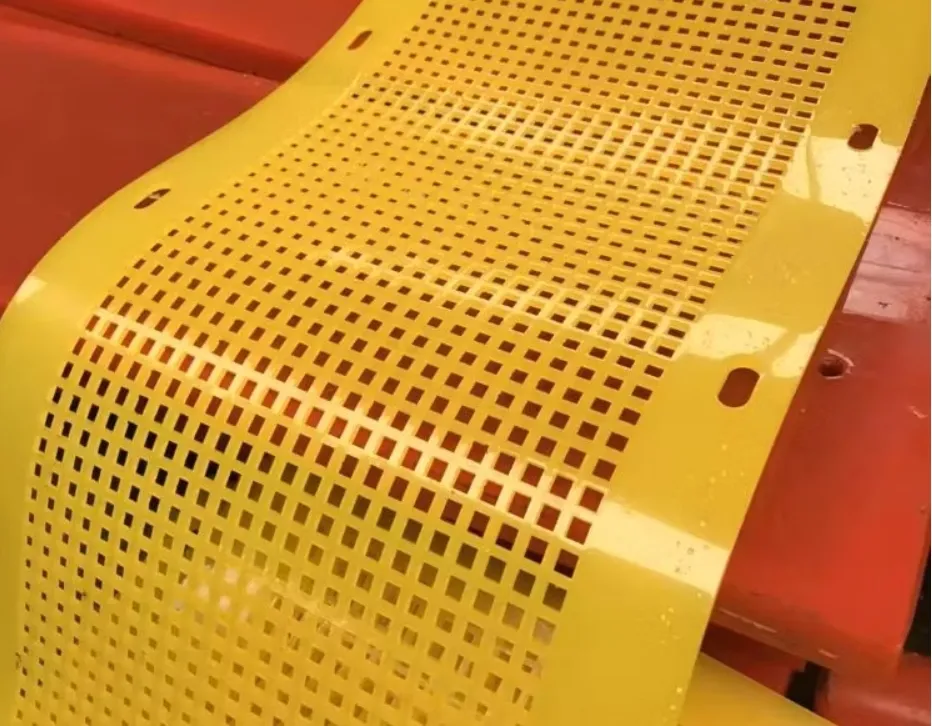

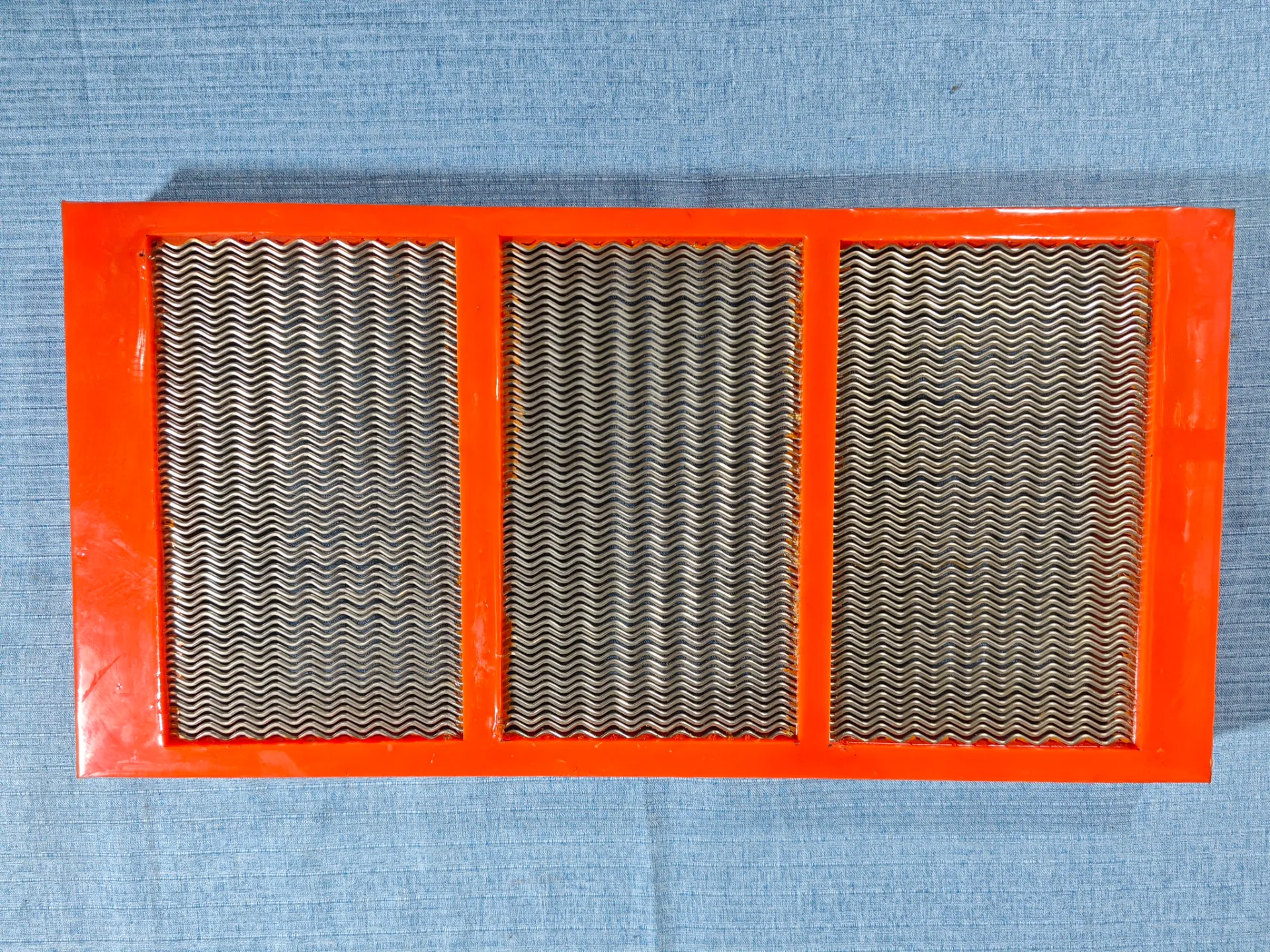

Self cleaning screen mesh plays a vital role in ensuring that the filtration process remains smooth and uninterrupted. The mesh is designed with a unique structure that allows for automatic cleaning without human intervention. This feature makes self cleaning screen mesh particularly valuable in industries where maintaining constant filtration is crucial to the overall success of the operation.

The self cleaning screen mesh works by using mechanisms such as vibration, scraping, or backwashing to clear any debris or particles that might accumulate on the screen surface. These mechanisms ensure that the mesh remains free of blockages, even when dealing with challenging materials. This is especially important in industries like mining, where large particles can easily clog traditional screens, leading to inefficiencies and downtime.

In addition to improving filtration efficiency, self cleaning screen mesh is designed to be highly resistant to wear and tear. The materials used in the mesh are chosen for their durability and ability to withstand harsh environments. Whether you're processing abrasive materials in mining or dealing with high-temperature liquids in wastewater treatment, self cleaning screen mesh can handle the toughest conditions without losing its effectiveness.

Furthermore, the self cleaning screen mesh reduces the need for regular cleaning maintenance. Traditional screens require frequent manual intervention to remove blockages, which can be time-consuming and labor-intensive. By using self cleaning screen mesh, industries can reduce the frequency of these maintenance tasks, freeing up valuable resources and allowing employees to focus on other critical aspects of the operation.

The Mechanisms Behind Self Cleaning Screens

The function of self cleaning screens relies on several mechanisms designed to prevent material buildup and maintain the flow of liquids or solids. These mechanisms vary depending on the type of self cleaning screen and the application, but they all aim to keep the screen surface free from blockages.

One of the most common cleaning mechanisms used in self cleaning screens is vibration. The screen is mounted on a frame that vibrates at a high frequency, which helps shake loose any particles or debris that might be clogging the screen. This vibration ensures that the screen remains clear, even during continuous operation.

Another mechanism employed by self cleaning screens is scraping. In this setup, a scraper or brush is used to physically remove any particles that are attached to the screen surface. This is particularly useful for sticky or dense materials that may be more difficult to dislodge through vibration alone. Scraping helps maintain the efficiency of the screen, ensuring that it continues to function effectively over time.

Backwashing is another popular cleaning method used in self cleaning screens. This involves flushing the screen with a reverse flow of water or another cleaning fluid, which helps to remove any particles that are clogging the mesh. Backwashing is particularly effective in applications where fine particles or organic matter are being processed, as it allows for thorough cleaning without requiring manual labor.

These self-cleaning mechanisms work in harmony to ensure that the screen remains clear and operational, which is essential for industries where uptime and continuous filtration are critical to success.

Self Cleaning Screens vs. Traditional Screens

When comparing self cleaning screens to traditional screening solutions, it becomes clear why they are becoming increasingly popular in industrial settings. Traditional screens often require frequent maintenance and cleaning to prevent blockages, leading to downtime and increased labor costs. In contrast, self cleaning screens offer a more efficient and cost-effective solution by automating the cleaning process and reducing the need for manual intervention.

One of the main differences between self cleaning screens and traditional screens is the level of maintenance required. Traditional screens often need to be manually cleaned or replaced, which can be time-consuming and costly. On the other hand, self cleaning screens eliminate the need for manual cleaning by using automated mechanisms that continuously clear the screen surface, allowing for uninterrupted filtration.

Another advantage of self cleaning screens is their ability to handle a wide range of materials without the risk of clogging. Traditional screens often struggle with challenging materials, especially those with varying particle sizes or sticky substances. Self cleaning screens are designed to deal with these materials effectively, ensuring that the filtration process remains smooth and efficient.

While self cleaning screens may have a higher initial cost compared to traditional screens, the long-term benefits in terms of reduced maintenance, increased efficiency, and lower downtime make them a smart investment. Industries that rely on continuous filtration can see significant improvements in productivity and cost savings by switching to self cleaning screens.

Self Cleaning Screens FAQs

What makes self cleaning screens different from traditional screens?

Self cleaning screens use automated cleaning mechanisms such as vibration, scraping, or backwashing to maintain their functionality, while traditional screens require manual cleaning and maintenance.

How does self cleaning screen mesh work to prevent blockages?

Self cleaning screen mesh uses mechanisms like vibration or scraping to dislodge and remove particles that accumulate on the screen, ensuring that the filtration process continues without interruption.

What industries benefit the most from self cleaning screens?

Industries such as mining, wastewater treatment, and food processing benefit the most from self cleaning screens due to the need for continuous filtration and the challenge of dealing with materials that can cause blockages.

Are self cleaning screens more cost-effective than traditional screens?

Although self cleaning screens may have a higher initial cost, their reduced maintenance and downtime make them a more cost-effective option in the long run, saving money on labor and increasing operational efficiency.

Can self cleaning screens handle both fine and coarse materials?

Yes, self cleaning screens are designed to handle a wide range of materials, from fine particles to coarse substances, making them versatile and reliable for various industrial applications.