For decades, aging water wells have struggled with declining efficiency, contamination risks, and frequent maintenance demands. The root cause often lies in outdated well screens that fail to meet modern operational standards. As a global leader in water infrastructure solutions, we specialize in revitalizing old wells by replacing obsolete components with advanced stainless steel well screens, water well screen pipes, and deep well screens designed for longevity and reliability. With our products exported to over 40 countries across six continents, we empower industries and communities to unlock the full potential of their water resources through cutting-edge technology and tailored engineering.

The Critical Role of Modern Well Screens in Revitalizing Aging Infrastructure

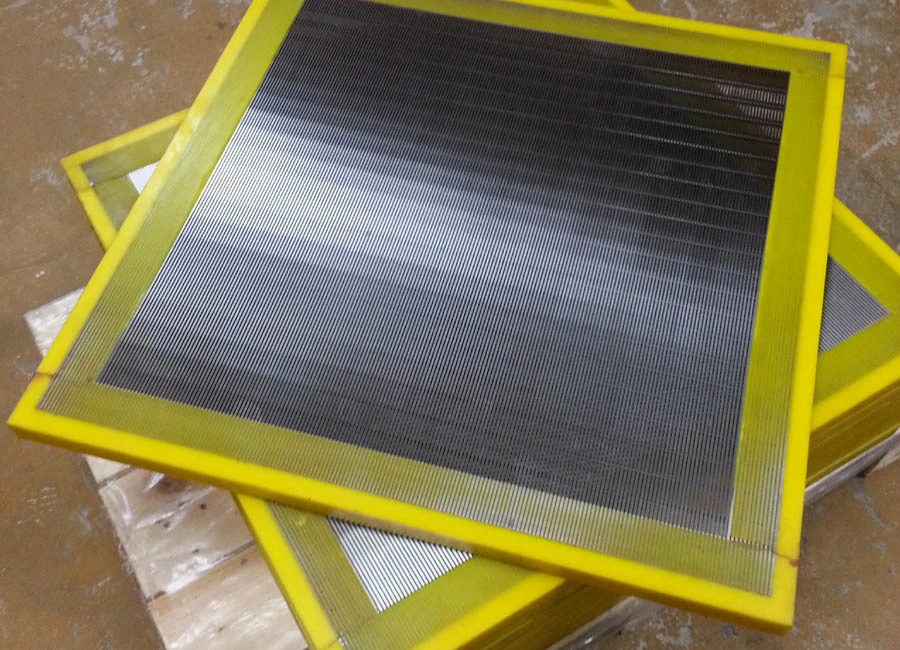

Aging wells face numerous challenges, including sediment infiltration, reduced flow rates, and corrosion damage. Traditional screens made from materials like mild steel or PVC often degrade over time, leading to clogged filters and compromised water quality. By contrast, stainless steel well screens offer unparalleled durability and resistance to chemical corrosion, ensuring consistent performance even in harsh environments. These screens are engineered with precision slot designs to prevent sand and debris from entering the well while maximizing water yield.

For deep well screen applications, our products are specifically designed to withstand high-pressure conditions and extreme depths. The robust construction of water well screen pipes ensures structural integrity, reducing the risk of collapse or deformation. By upgrading to modern screens, operators can extend the lifespan of their wells by decades, minimize downtime, and reduce long-term maintenance costs. Case studies from regions like arid Africa and industrial Asia demonstrate how our solutions have transformed failing wells into reliable water sources for agriculture, municipalities, and manufacturing facilities.

Choosing the Right Well Screen for Sale: Factors to Consider

Selecting the optimal well screen for sale requires a thorough understanding of site-specific conditions. Geological factors, water chemistry, and intended usage all play a role in determining whether a stainless steel well screen, deep well screen, or specialized water well screen pipe is most suitable. For instance, coastal areas with saline groundwater benefit from corrosion-resistant stainless steel, while regions with high sediment loads require screens with narrower slot openings to prevent clogging.

Our team works closely with clients to analyze well depth, aquifer characteristics, and flow rate requirements. Customizable options include varying slot sizes, screen diameters, and connection types to ensure compatibility with existing infrastructure. Additionally, our deep well screens incorporate reinforced welding techniques to handle the mechanical stresses of deep installations. By prioritizing adaptability, we deliver solutions that align with both technical specifications and budgetary constraints, making modernization accessible for wells of all sizes.

Proper installation is critical to maximizing the benefits of a new well screen for sale. Before retrofitting an old well, a comprehensive inspection should identify issues like casing damage or borehole instability. Our stainless steel well screens are designed for seamless integration with most well casings, minimizing the need for extensive modifications. For deep well screen deployments, specialized tools and techniques ensure precise placement at targeted depths, avoiding misalignment that could compromise performance.

Post-installation, regular monitoring helps detect early signs of wear or sediment buildup. Unlike outdated screens, our water well screen pipes feature smooth surfaces that discourage bacterial growth and mineral scaling, simplifying maintenance. Clients in regions like South America and Oceania have reported significant improvements in water clarity and pump efficiency after adopting our screens, underscoring the importance of combining quality products with expert installation.

Global Impact: How Modern Well Screens Transform Water Access

From remote villages to urban industrial zones, upgrading to advanced well screens for sale has far-reaching implications. In Africa, communities previously reliant on contaminated shallow wells now access clean water through stainless steel well screens installed in deeper, protected aquifers. In Europe, municipalities use our deep well screens to secure sustainable water supplies for growing populations. Agricultural sectors in Asia and North America leverage high-capacity water well screen pipes to support irrigation systems, boosting crop yields while conserving resources.

Our global footprint—spanning over 40 countries—reflects a commitment to universal water security. By prioritizing innovation and customer-centric design, we enable clients to future-proof their infrastructure against climate challenges and increasing demand.

Upgrading Old Wells with Modern Well Screens: FAQs

What are the signs that my well needs a new well screen?

Common indicators include reduced water flow, sand or sediment in the water, and frequent pump failures. If your well is over 20 years old, upgrading to a stainless steel well screen or deep well screen can address these issues effectively.

How does a stainless steel well screen prevent corrosion?

Stainless steel contains chromium, which forms a passive oxide layer that resists rust and chemical reactions. This makes it ideal for environments with acidic or saline groundwater, ensuring long-term durability compared to traditional materials.

Can a water well screen pipe be customized for unusual well depths?

Yes. Our water well screen pipes are tailored to fit specific depth requirements, whether for shallow residential wells or industrial deep well screen applications. Custom slot patterns and diameters ensure optimal performance in diverse geological conditions.

Is it cost-effective to replace an old well screen instead of drilling a new well?

Absolutely. Retrofitting an existing well with a modern well screen for sale is typically 30–50% cheaper than drilling a new well, while delivering comparable or superior performance.

How long does a stainless steel well screen last?

With proper installation and maintenance, our stainless steel well screens can last over 50 years, making them a sustainable investment for long-term water security.

Don’t let outdated technology limit your water supply’s potential. Explore our range of stainless steel well screens, water well screen pipes, and deep well screens to breathe new life into aging infrastructure. With a proven track record across six continents, we deliver solutions that combine innovation, reliability, and affordability. Visit our website to consult with our experts and discover how modern well screens can transform your operations.