In the demanding world of industrial separation and filtration, efficiency, durability, and precision are paramount. Equipment subjected to high pressures, abrasive materials, and continuous operation requires screening solutions built to last and perform consistently. This is where specialized manufacturers like MUTO Wire Screen Co., Ltd. excel. Founded in Anping County – renowned globally as "The Capital of Wire Mesh" – MUTO has evolved significantly since its beginnings as Anping Zhanyuan Wire Mesh Factory in 2010. Today, it stands as a qualified and respected Chinese manufacturer, celebrated for its deep expertise in industrial sieve screens, particularly wedge wire screen technology, mining solutions, and the machinery to produce them. Embracing smart technology as a core principle, MUTO has secured 12 screen technology patents and 4 equipment patents, earning prestigious recognitions like "National Science and Technology Small & Medium-Sized Enterprises" (2023) and "High-Tech Enterprises" (2024). With strategic expansions including branches in Pingdingshan, Henan (2019), and Jixi, Heilongjiang (2023), and substantial manufacturing facilities (2500 sqm for screens, 2000 sqm for equipment), MUTO leverages its technical R&D prowess to deliver robust solutions globally.

Engineering Excellence in Wedge Wire Screen Technology

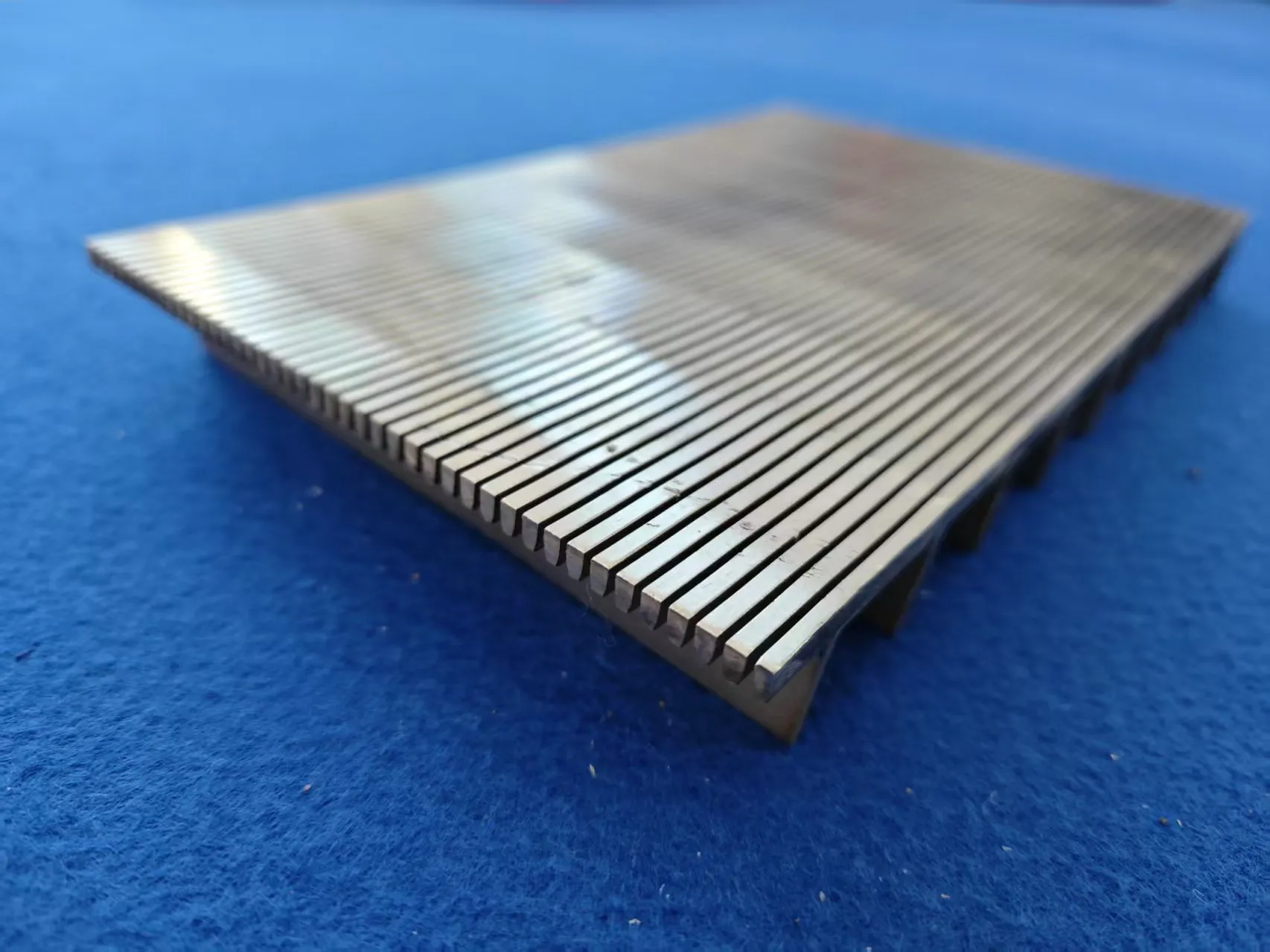

The cornerstone of high-pressure screening performance often lies in the design and manufacturing of the wedge wire screen. Also known as a V-wire screen or wedge wire mesh, this technology is fundamentally different from woven wire cloth. It is constructed by precisely welding profile wires (with a wedge-shaped cross-section) onto robust support rods using specialized, high-precision welding equipment – an area where MUTO's own equipment patents come into play. This unique structure creates slots with precise, uniform openings that are non-clogging and exceptionally strong.

The advantages of wedge wire screen construction under high-pressure conditions are significant:

- Structural Integrity:The welded construction provides immense mechanical strength, allowing the screen to withstand high flow rates, heavy material loads, and significant pressure differentials without deformation or slot widening.

- Precision Slot Control:Slot sizes are determined by the spacing between the profile wires during welding, offering exceptional accuracy (tolerances as tight as ±5 microns) and consistency across the entire panel. This is crucial for precise particle separation.

- Blinding & Clogging Resistance:The V-shaped profile creates a smooth, tapered slot opening. Solids tend to slide over the top edge of the wedge wire, minimizing the risk of particles becoming lodged and blinding the screen surface, ensuring sustained flow and efficiency.

- High Open Area:Despite the robust construction, wedge wire mesh designs can achieve a high percentage of open screening area relative to the total surface, maximizing throughput capacity.

- Material Versatility:Wedge wire screens can be manufactured from a wide range of corrosion-resistant and wear-resistant alloys, tailored to the specific chemical and abrasive nature of the process fluid or slurry.

MUTO's extensive experience and focus on "smart technology" directly translate into the reliability of their wedge wire screen products under extreme conditions.

Versatile Applications of Wedge Wire Mesh Systems

The inherent strength, precision, and resistance to blinding make wedge wire mesh systems indispensable across numerous high-pressure and demanding industries:

- Mining & Mineral Processing:Critical for sizing, dewatering, desliming, and scalping ores and minerals under high slurry pressures. Used in vibrating screens, static sieves, and centrifuges.

- Oil & Gas Production:Essential components in sand control screens (well screens) for downhole filtration, protecting equipment from abrasive particles under immense reservoir pressures. Also used in produced water treatment and filtration skids.

- Power Generation:Employed in fuel and ash handling systems, cooling water intake screens, and FGD (Flue Gas Desulphurization) processes where reliability under pressure and corrosion resistance are vital.

- Chemical & Petrochemical Processing:Used for catalyst retention, filtration under pressure, and separation tasks involving aggressive chemicals and high temperatures/pressures.

- Pulp & Paper:Key for pulp screening, filtrate screens in pressure filters, and wastewater treatment within mills.

- Water & Wastewater Treatment:Integral to drum screens, intake screens, and pressure filters for municipal and industrial water treatment plants.

MUTO's comprehensive range caters to these diverse needs, offering both flat and cylindrical wedge wire mesh configurations.

Optimized Performance in Sieve Bend Screen Operations

A particularly effective application of wedge wire screen technology is the sieve bend screen. This curved screen panel operates on a unique principle: a feed slurry is introduced tangentially at the top of the concave surface. The liquid and fine particles pass through the precisely slotted wedge wire mesh, while the coarser solids are conveyed by inertia and gravity along the curved surface and discharged at the bottom.

Sieve bend screens offer distinct advantages:

- High Capacity:Capable of handling very large flow rates efficiently due to the gravity-assisted separation and high open area of the wedge wire

- Blinding Resistance:The continuous "washing" action of the feed slurry over the curved wedge wire mesh surface, combined with the non-clogging slot design, minimizes blinding.

- Low Maintenance:No moving parts and the inherent durability of the wedge wire screen construction lead to reduced downtime and maintenance costs.

- Effective Fine Screening:Excellently suited for dewatering, desliming, and removing fine particles from coarse fractions in mineral processing and aggregate industries.

MUTO's expertise in designing and manufacturing robust sieve bend screens ensures optimal performance in these high-throughput, often abrasive applications.

FAQs about High-Pressure Wedge Wire Screen Solutions

How does a wedge wire screen handle extremely high-pressure environments, such as in oil well applications?

The structural integrity of a wedge wire screen is key. The continuous welding of the wedge-shaped profile wires onto sturdy support rods creates a monolithic, rigid panel. This construction, especially when fabricated from high-strength alloys like Duplex stainless steel, provides exceptional resistance to collapse, bursting, and fatigue under sustained high pressures encountered downhole or in pressurized vessels. Precise slot control is maintained even under load.

What are the primary advantages of using wedge wire mesh compared to traditional woven wire mesh for fine filtration under pressure?

Wedge wire mesh offers superior strength and slot stability under pressure, significantly reducing the risk of slot deformation or wire movement that can occur with woven mesh. Its V-wire profile provides inherent non-blinding characteristics, crucial for maintaining flow rates in pressurized systems. The precision welding allows for much finer and more consistent slot sizes (down to 20 microns) than typically achievable with woven wire, making it ideal for high-pressure fine filtration.

In what specific mineral processing applications is a sieve bend screen most effective?

Sieve bend screens excel in high-volume, coarse/fine wet separation tasks within mineral processing. Key applications include primary desliming of crusher feeds, dewatering and rinsing of coarse aggregates, scalping ahead of finer screens or hydrocyclones, and recovering fine solids from thickener overflows. Their ability to handle large slurry flows with minimal maintenance makes them particularly effective for these demanding duties.

Can MUTO customize the slot size and profile wire dimensions for specific process requirements in their wedge wire screens?

Absolutely. Customization is a core strength. MUTO can manufacture wedge wire screens with slot sizes ranging precisely from 20 microns to 3000 microns (±5 micron tolerance achievable). They also offer various wedge wire profile dimensions (e.g., 0.5x1.5mm, 1x2mm, 3x5mm) and support rod sizes, allowing optimization for specific flow rates, solids loading, wear resistance, and pressure conditions. Material selection is also fully customizable.

What materials are commonly used for wedge wire screens in highly corrosive and abrasive high-pressure environments?

For severe service, MUTO utilizes high-performance alloys beyond standard stainless steels. This includes Super Duplex stainless steels (offering superior strength and chloride resistance), Nickel alloys like Hastelloy C-276 (excellent for highly corrosive acids and chlorides), and sometimes specialized coatings. The choice depends on the specific chemical composition, temperature, pressure, and abrasiveness of the process stream.

High-pressure screening and filtration demand robust, reliable, and precisely engineered solutions. MUTO Wire Screen Co., Ltd., leveraging its heritage in Anping County and driven by a commitment to smart technology and innovation, stands as a leading authority in this field. Their expertise in wedge wire screen and wedge wire mesh manufacturing, backed by significant R&D investment and patented technologies, delivers unparalleled performance in the most challenging environments. From the structural integrity enabling downhole oilfield applications to the high-throughput efficiency of sieve bend screens in mineral processing, MUTO's products are engineered for longevity, precision, and optimal separation efficiency under pressure. With extensive customization capabilities, state-of-the-art facilities, and a proven track record recognized by national high-tech certifications, MUTO provides industrial partners worldwide with dependable, high-performance screening solutions for their critical operations.