Wedge Wire Screen Machine: An Industrial Tool for Creating High Strength, Durable, and Efficient Filtering

In many aspects of industrial production, filtration and screening play a key role, and Wedge Wire Screen Machine is the core Wedge Wire Screen Machine that produces wedge-shaped screens that meet the needs of high strength, durability, and high efficiency filtration. Its technology and performance profoundly affect the production quality and efficiency of multiple industries.

Wedge Wire Screen Machine operates in conjunction with advanced welding technology and precision machinery to ensure welding quality

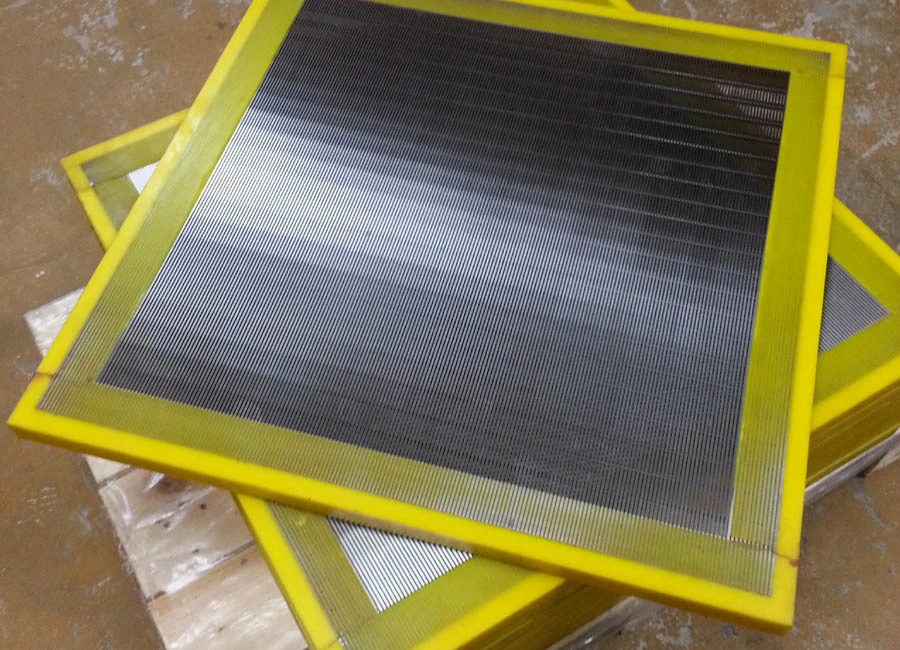

The wedge wire screen welding machine adopts an intelligent control system that can accurately adjust welding parameters such as current, voltage, welding time, and pressure. With high-precision mechanical positioning devices, the wedge wire and support bar are precisely fixed in the predetermined position. During the welding process, the high temperature instantly melts the contact point, causing the two to fuse tightly and form a firm weld joint. This precise welding process not only ensures the integrity of the wire mesh structure, but also lays the foundation for its high strength and durability.

Wedge Wire Screen Machine produces wedge-shaped wire mesh with significant advantages in strength, durability, and filtration efficiency

In terms of strength, precise welding technology ensures tight connections between various parts of the wire mesh, which can withstand significant external impacts and pressures and is not easily deformed or damaged; In terms of durability, using high-quality materials combined with mature welding technology can effectively resist corrosion and wear, and extend the service life; Efficient filtration benefits from the unique cross-sectional design of wedge-shaped fibers, which have stable and uniform gaps that can efficiently intercept particles of different sizes and impurities, and are not easily clogged, ensuring efficient and continuous filtration.

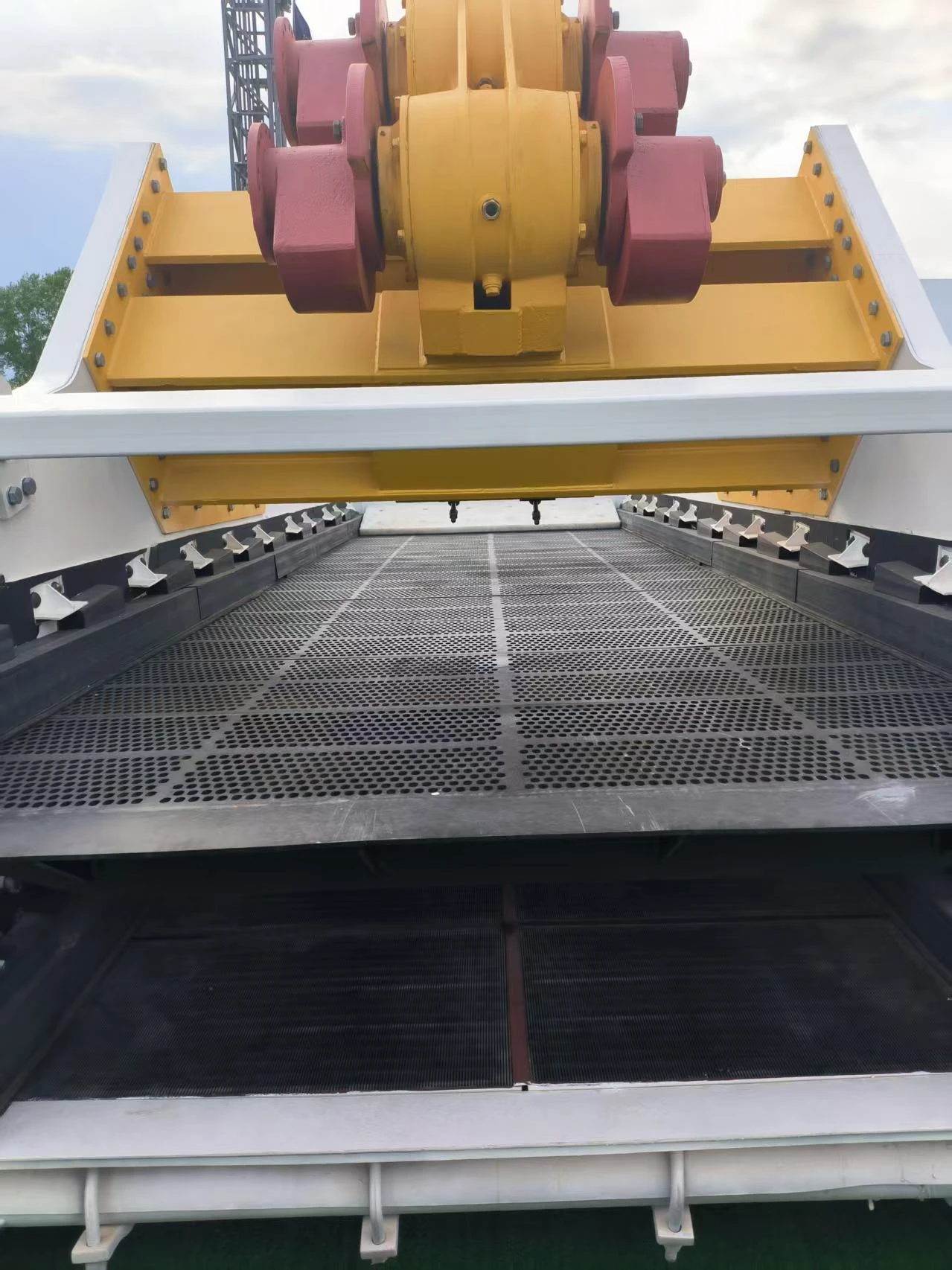

Wedge Wire Screen Machine is widely used in multiple industries with strict filtering requirements

In the mining industry, wedge wire mesh is used for ore screening in wedge wire screen welding machines. With high strength and durability, it can work stably for a long time in complex and harsh working conditions, efficiently separating ore from impurities; In the chemical industry, wedge-shaped wire mesh used for liquid filtration ensures the purity of chemical raw materials and products due to its corrosion resistance and efficient filtration performance; In the field of environmental protection, the wedge-shaped wire screen filter in the Wedge Wire Screen Machine for sewage treatment achieves efficient interception of pollutants in sewage, helping to purify and recycle water resources.

With the continuous advancement of industrial technology, Wedge Wire Screen Machine is also constantly innovating and upgrading

The application of new welding materials further enhances welding strength and corrosion resistance; The introduction of intelligent control system has achieved real-time monitoring of the operating status and automatic parameter adjustment of Wedge Wire Screen Machine, further improving welding quality and production efficiency; The improvement of automation level reduces manual intervention, lowers production costs and human errors.

In summary, Wedge Wire Screen Machine plays an important role in various fields of industrial production by creating wedge-shaped screens with high strength, durability, and efficient filtering characteristics through its advanced technology and processes. Whether it is the harsh mining environment or the highly precise chemical and environmental industries, it provides reliable guarantees for the stable operation of production and the improvement of product quality, and is an indispensable and important Wedge Wire Screen Machine in the process of industrial development.

Wedge Wire Screen Machine FAQs

What are the main advantages of Wedge Wire Screen Machine?

The Wedge Wire Screen Machine is made of high-strength stainless steel wedge wire welded together, with a stable structure and strong impact and deformation resistance. Its unique V-shaped gap design enables efficient filtration while possessing excellent wear and corrosion resistance, making it suitable for harsh working conditions such as mining and wastewater treatment, with a lifespan far exceeding that of ordinary mesh screens.

Why is it said that Wedge Wire Screen Machine screens have higher filtration efficiency?

The gap of the wedge-shaped wire mesh has a trapezoidal cross-section, narrow at the top and wide at the bottom. This design can effectively prevent particle blockage and achieve a "self-cleaning" effect. At the same time, the gap size is precise (with a minimum of 0.02mm), which can filter materials of different particle sizes in stages, improving filtration accuracy and throughput (processing capacity).

Which industries most commonly use this Wedge Wire Screen Machine?

Mainly used in fields that require high filtration strength and durability, such as:

Mining: used for ore grading and tailings dewatering;

Environmental protection: fine screens and sludge dewatering in sewage treatment plants;

Food and chemical industry: precision filtration of liquid raw materials;

Energy: Solid liquid separation in oil drilling.

How to maintain Wedge Wire Screen Machine to extend its lifespan?

Regular flushing: Use high-pressure water guns to remove residue from gaps;

Check welding points: avoid local stress cracking;

Chemical protection: If in contact with highly corrosive media, it is recommended to use 316L stainless steel or coating reinforcement.

Under normal use, the lifespan of high-quality wedge-shaped wire mesh can reach more than 10 years.

What parameters should be considered for customizing Wedge Wire Screen Machine?

Choose according to specific working conditions:

Gap accuracy: customized according to the particle size of the filtering material (such as 0.1mm~5mm);

Wire diameter and spacing: affect strength and flux, usually wire diameter of 2mm~8mm;

Material: 304/316 stainless steel, duplex steel or special alloy;

Structural forms: arc-shaped screen, flat screen, or drum screen, etc.