Precision welding creates the cornerstone of industrial filters - Analysis of Wedge Wire Screen Welding Machine

In the fields of industrial filtration, screening, etc., wedge-shaped wire mesh is widely used due to its unique structure and excellent performance. As a dedicated Machine de soudage d'écrans à fils en coin for manufacturing this key component, Wedge Wire Screen Welding Machine has become the cornerstone of ensuring industrial production quality with its precision technology and efficient performance.

The working principle of Wedge Wire Screen Welding Machine is based on advanced welding technology and precise mechanical structure

The Machine de soudage d'écrans à fils en coin precisely controls the welding current, voltage, and time, coupled with a high-precision mechanical transmission system, to accurately align and firmly weld the wedge wire with the support bar. Taking resistance welding technology as an example, when current passes through the contact area between the wedge-shaped wire and the support bar, the resistance heat generated causes the contact point to quickly melt, forming a firm weld under pressure, ensuring welding strength and stability, and laying the foundation for the reliable performance of the wedge-shaped wire mesh.

Compared to traditional welding methods, Wedge Wire Screen Welding Machine has significant advantages

Firstly, high-precision welding ensures that the weld seam is uniform and firm, greatly improving the quality and service life of the wedge-shaped wire mesh; Secondly, the automated operation mode significantly improves production efficiency, reduces manual intervention, not only lowers labor costs, but also avoids unstable welding quality caused by human factors; Thirdly, the Machine de soudage d'écrans à fils en coin can adjust parameters according to different specifications of wedge wires and support bars, achieving diversified product production and meeting the needs of different industrial scenarios.

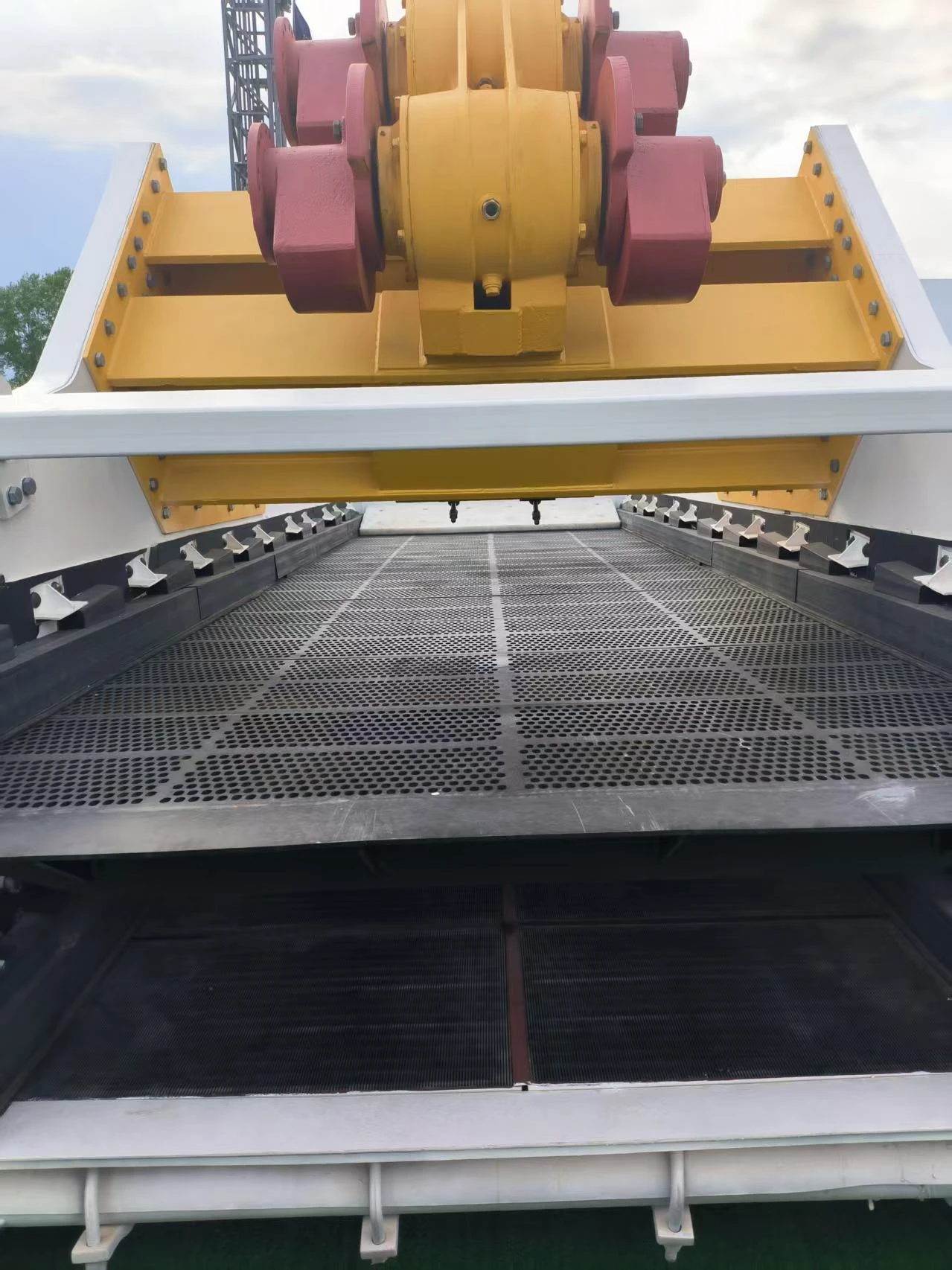

Wedge Wire Screen Welding Machine plays an important role in multiple industries

In the field of oil and gas extraction, the wedge-shaped wire mesh welded is used for underground filtration. The Machine de soudage d'écrans à fils en coin can withstand the impact of high-speed fluids under complex working conditions; In the water treatment industry, wedge-shaped wire mesh filters made by welding can efficiently intercept suspended solids in wastewater; In the food processing industry, wedge-shaped wire mesh produced by welding processes that meet hygiene standards ensures the safety and reliability of food raw material filtration, helping various industries to produce efficiently and stably.

With the continuous advancement of industrial technology, Wedge Wire Screen Welding Machine is also continuously innovating and developing

On the one hand, the integration of intelligent technology enables Machine de soudage d'écrans à fils en coin to achieve automatic detection, fault diagnosis, and parameter optimization; On the other hand, the application of new materials and processes has further improved the quality and efficiency of welding. In the future, Wedge Wire Screen Welding Machine will develop towards greater precision, intelligence, and efficiency to meet the increasingly stringent requirements of industrial production.

In summary, Machine de soudage d'écrans à fils en coin has become an indispensable and important tool in industrial production due to its precise welding principle, outstanding performance advantages, wide industry applications, and promising development prospects. It not only ensures the quality and production efficiency of wedge-shaped wire mesh, but also provides reliable support for filtration, screening and other processes in various industries, promoting industrial production towards high quality and efficiency.

Wedge Wire Screen Welding Machine FAQs

What is the main purpose of Wedge Wire Screen Welding Machine?

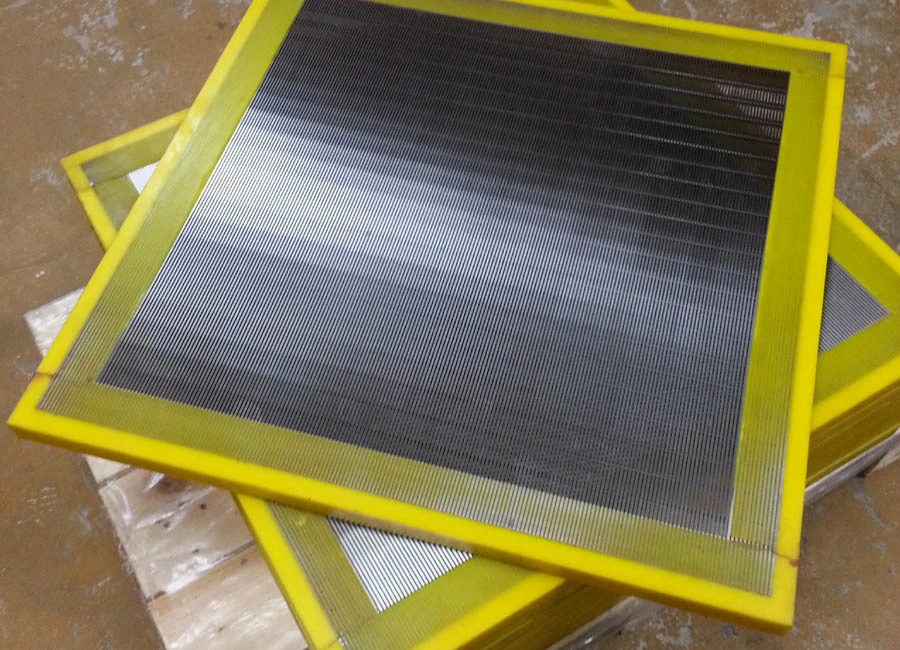

This Wedge Wire Screen Welding Machine is specifically designed for welding wedge wire screens. By precision welding, the wedge wire (V-shaped cross-section metal wire) is firmly connected to the support bar to form a high-precision filter screen. It is widely used in filtration and separation processes in industries such as petroleum, chemical, water treatment, and mining.

What are the core advantages of Wedge Wire Screen Welding Machine?

High precision welding: Ensure uniform spacing between wedge-shaped wires and controllable filtering accuracy.

Automated production: supports continuous welding, improves efficiency, and reduces manual errors.

Strong weld seam: using resistance welding or laser welding technology, the weld seam has high tensile strength and corrosion resistance.

Customized design: can adapt to different wire diameters, screen sizes, and materials (such as stainless steel, titanium alloy, etc.).

What are the key components of Wedge Wire Screen Welding Machine?

Wire feeding system: precise delivery of wedge-shaped wires and support bars.

Welding head: Perform high-frequency resistance welding or laser welding.

Control system: PLC or CNC system regulates welding parameters (current, pressure, speed, etc.).

Cooling device: prevents welding from overheating and deformation.

How to choose the appropriate Wedge Wire Screen Welding Machine model?

Evaluation should be based on the following parameters:

Screen specifications: wire diameter (usually 0.5mm~5mm), screen width/length.

Material requirements: such as differences in welding parameters between 304/316 stainless steel.

Capacity demand: single machine capacity (such as welding area per hour) and degree of automation.

Additional features: such as automatic alignment, online detection, etc.

What quality tests are required for the welded screen of Wedge Wire Screen Welding Machine?

Weld strength test: Tensile test verifies the reliability of the welding point.

Dimensional accuracy testing: Use calipers or optical measurements to confirm wire spacing errors.