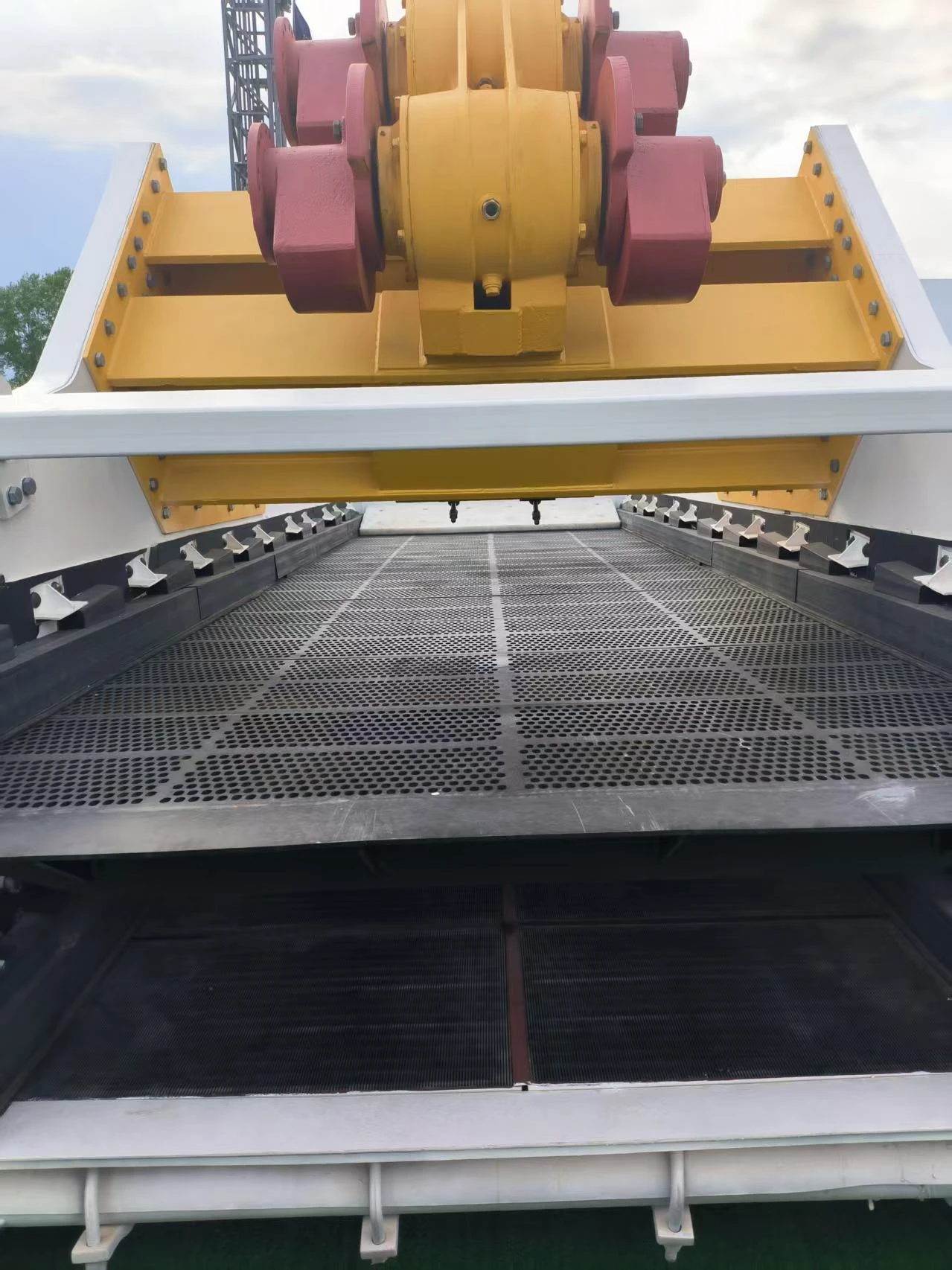

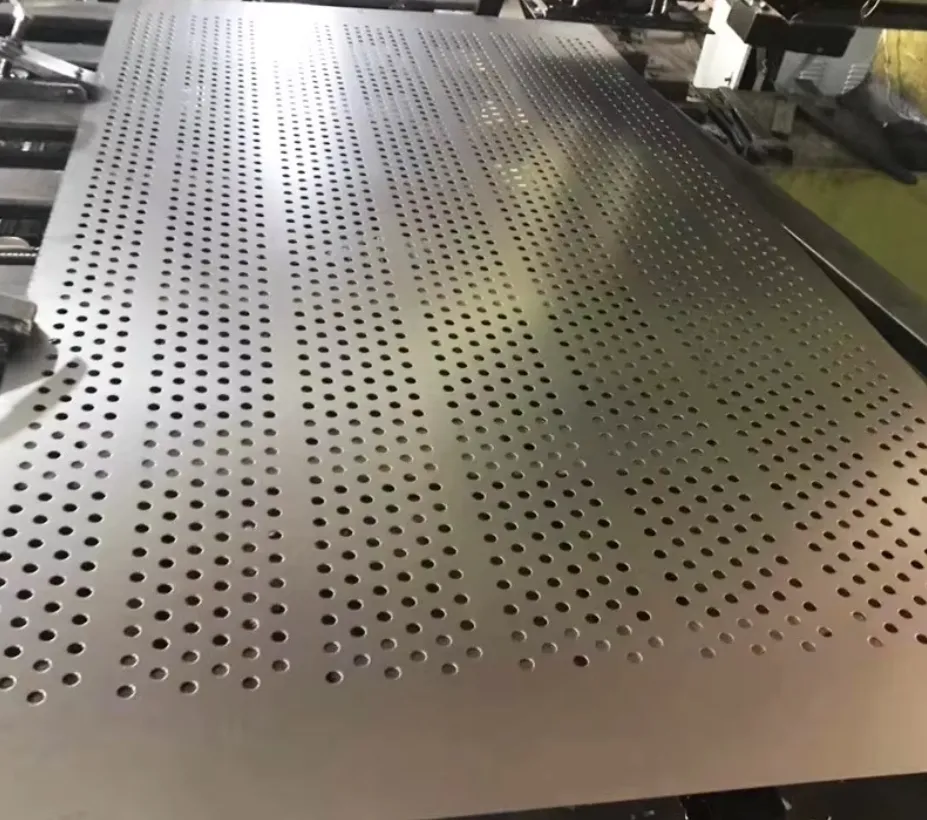

In gold mining and processing operations, perforated steel panels serve as the backbone of material separation and classification. These screens are engineered to withstand abrasive environments while maintaining precise hole patterns that dictate sorting efficiency. The ideal hole size depends on the granularity of the ore being processed—smaller holes retain finer particles for thorough extraction, while larger apertures prioritize high-volume throughput. For instance, in alluvial gold recovery, screens with millimeter-scale perforations effectively trap gold-bearing sediments while allowing lighter debris to pass through. Beyond size, the geometry of holes—whether round, slotted, or hexagonal—also influences flow dynamics and minimizes clogging risks.

Material strength is non-negotiable for perforated steel panels exposed to constant mechanical stress. High-carbon steel or abrasion-resistant alloys are preferred for their ability to endure impact from falling rocks and repetitive vibrations. Additionally, surface treatments like galvanization or polymer coatings enhance corrosion resistance in humid or chemically active environments. A well-designed panel balances rigidity with flexibility, ensuring it doesn’t warp under load yet remains easy to install or replace.

Enhancing Longevity in Perforated Screen Plate Systems

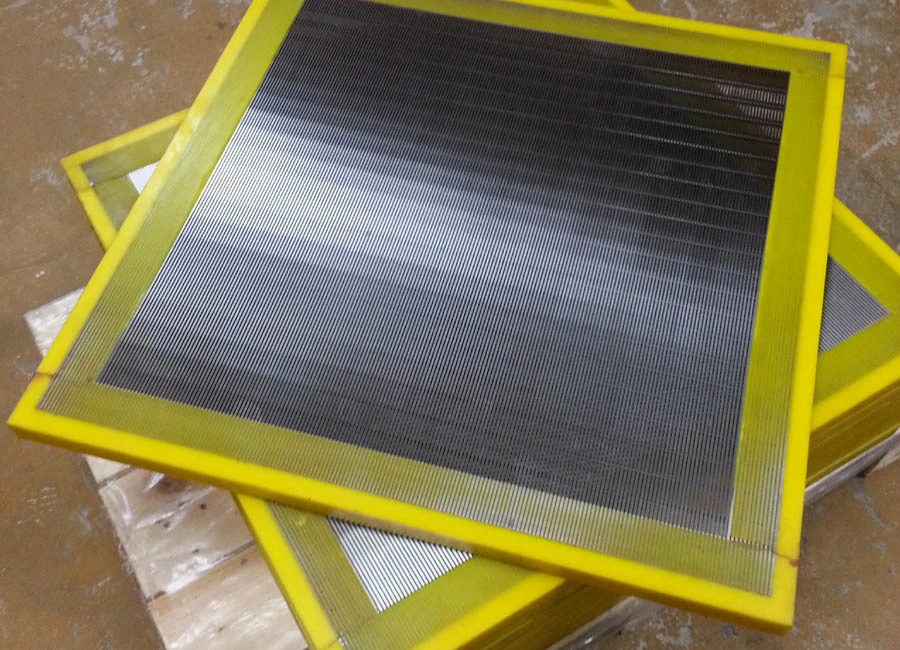

The durability of perforated screen plates hinges on strategic material selection and manufacturing precision. In gold ore crushing circuits, screens must resist wear from sharp-edged fragments and high-velocity impacts. Hardened steel grades, such as AR400 or manganese steel, are widely adopted for their exceptional hardness-to-toughness ratio. These materials undergo laser cutting or stamping to create uniform perforations that retain structural integrity even after prolonged use.

Another critical factor is the alignment of perforations with operational flow rates. Screens installed in high-capacity hammer mills, for example, require staggered hole patterns to distribute stress evenly and prevent premature failure. Reinforced edges or bolted frames further mitigate deformation risks. For operations in regions with extreme temperatures or salinity, stainless steel variants offer superior resistance to oxidation, extending service life and reducing downtime.

Hammer Mill Screen: Balancing Throughput and Precision

Within grinding circuits, hammer mill screens act as gatekeepers, determining the fineness of crushed ore. Their design directly impacts energy efficiency and gold recovery rates. A screen with excessively small holes may increase processing time and power consumption, while oversized perforations risk losing valuable particles. The optimal configuration aligns with the mill’s rotational speed and feed rate—variables that dictate how aggressively materials are pulverized.

Flow rate handling is another pivotal consideration. Screens must facilitate smooth material passage without bottlenecks, especially in operations processing thousands of tons daily. Angled perforations or tapered designs help maintain consistent flow, reducing the likelihood of blockages. Additionally, modular screen systems allow quick adjustments to hole sizes, enabling operators to adapt to varying ore grades without halting production.

Versatility of Perforated Sheet Solutions in Gold Processing

Perforated sheets offer unmatched adaptability across gold operations, from primary crushing to final refinement. Their applications extend beyond screening—they serve as liners for chutes, protective guards for machinery, and even decorative elements in facility architecture. In leaching tanks, perforated sheets with micro-perforations ensure even distribution of cyanide solutions, maximizing gold dissolution rates.

Customization is key to meeting site-specific demands. Perforation density, sheet thickness, and open area ratios are tailored to harmonize with existing equipment and workflow. For instance, sheets used in trommel screens prioritize high open areas to accelerate material movement, while those in settling tanks focus on filtration precision.

Design Considerations for a Perforated Plate Screen in Gold Operations: FAQs

How do I choose the right perforated steel panels for my gold mine?

Consider factors like ore hardness, particle size distribution, and environmental conditions. Screens for abrasive ores require hardened steel, while humid climates demand corrosion-resistant coatings.

Can perforated screen plates be reused after wear?

Yes, many screens can be refurbished by welding or resurfacing, provided the core structure remains intact. Regular inspections help identify salvageable components.

What maintenance ensures hammer mill screen longevity?

Routine cleaning to remove lodged debris and periodic alignment checks are essential. Avoid overloading the mill to prevent undue stress on the screen.

Are custom-designed perforated sheets cost-effective?

Absolutely. Tailored designs minimize material waste and optimize performance, reducing long-term operational costs through improved efficiency.

How do perforated sheets impact environmental sustainability?

By enhancing material recovery rates, they reduce waste generation. Durable designs also lower replacement frequency, conserving resources.

With over four decades of expertise, our perforated steel panels, perforated screen plates, hammer mill screens, and perforated sheets have been trusted by clients across 40+ countries. From Asia to Oceania, we deliver robust, customized solutions that withstand the rigors of gold operations. Explore our product range today and discover how our screens can elevate your operational efficiency. Visit our website to connect with our team for a tailored quotation.