In industries dealing with corrosive ores, the choice of material for perforated steel panels is critical. Stainless steel, renowned for its corrosion resistance, stands out as the optimal choice for perforated screen plates in wet or chemically aggressive settings. Unlike traditional materials like carbon steel or plastics, stainless steel inherently resists rust, pitting, and degradation caused by moisture, acidic slurries, or saline conditions. This durability ensures that Hammer mill screens and other filtration systems maintain structural integrity even under prolonged exposure to harsh ore processing environments.

The secret lies in stainless steel’s chromium content, which forms a passive oxide layer on the surface, shielding the metal from oxidative damage. For perforated sheets used in ore sorting or dewatering, this property translates to reduced maintenance costs and extended service life. Additionally, grades like 316L stainless steel offer enhanced resistance to chlorides, making them ideal for coastal mining operations or facilities using seawater in processing. By prioritizing material science, industries can achieve operational efficiency while minimizing downtime caused by equipment failure.

Our global clientele, spanning Asia, Europe, Africa, and beyond, consistently highlights the reliability of stainless steel perforated screen plates in their operations. Whether extracting precious metals or processing industrial minerals, the adaptability of these screens to diverse climatic and chemical conditions underscores their universal appeal.

Tailoring Perforated Steel Panels for Maximum Efficiency

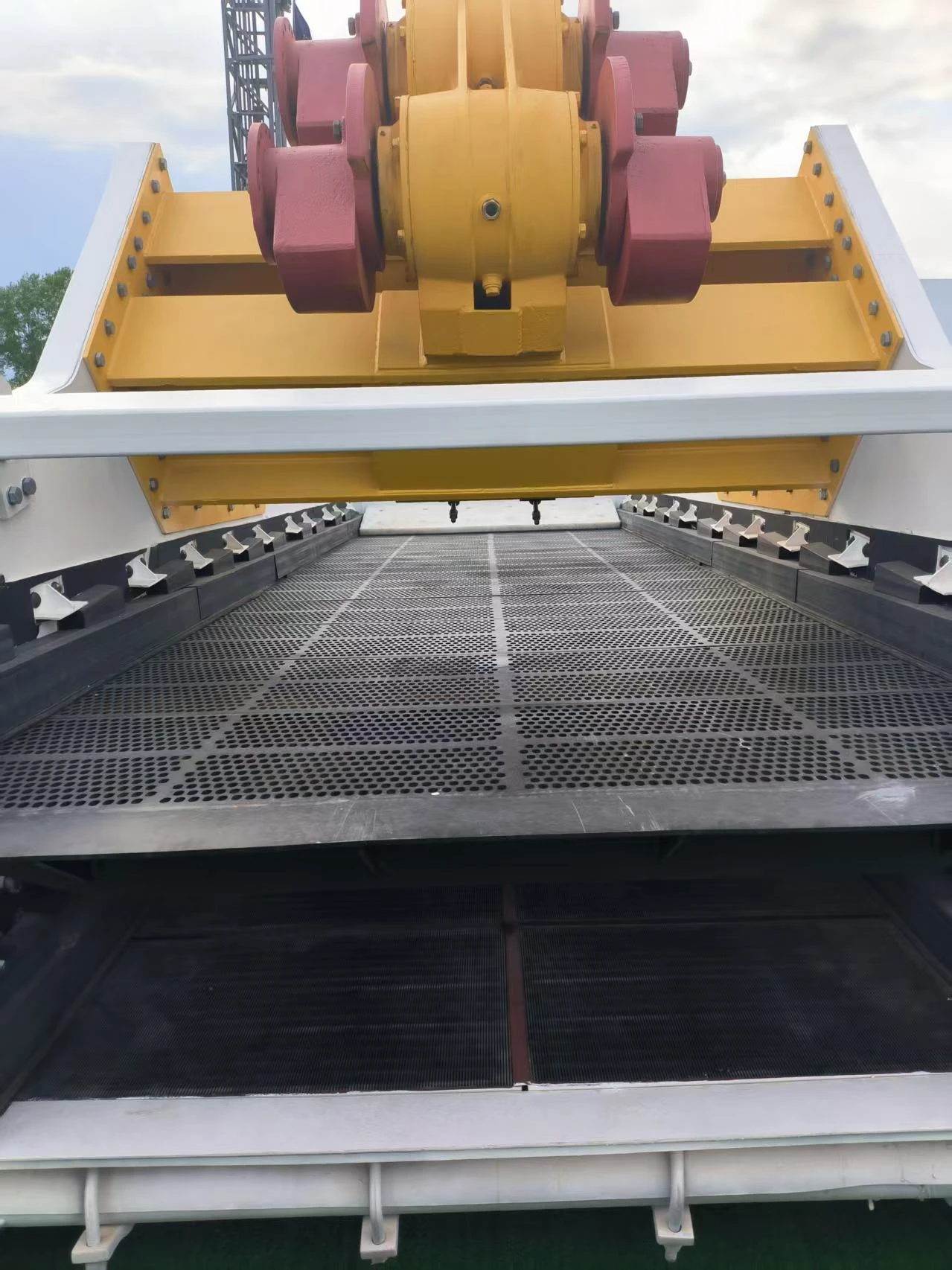

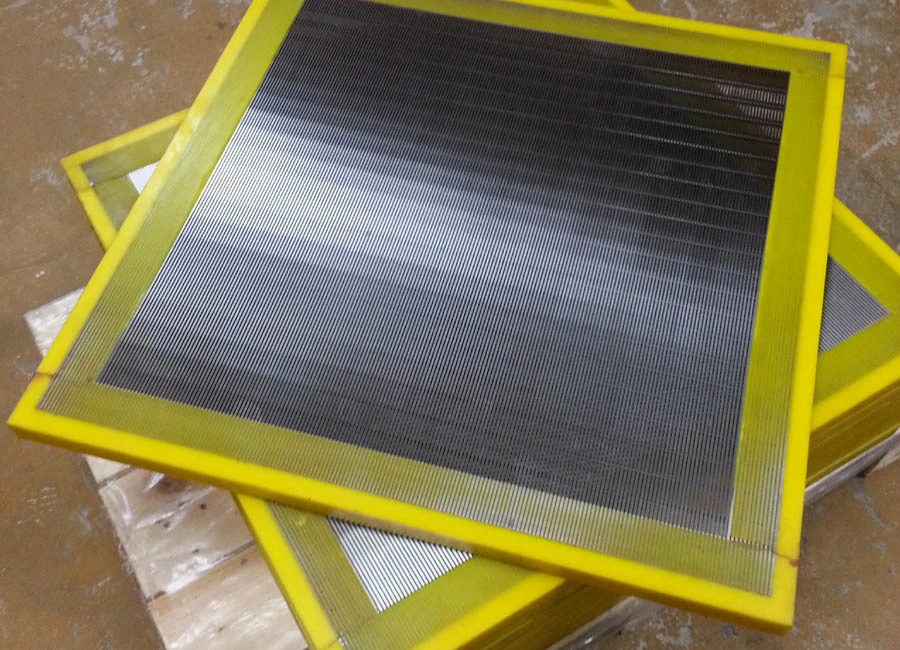

The effectiveness of perforated steel panels in corrosive environments hinges not just on material choice but also on precision engineering. Customizable hole patterns, aperture sizes, and sheet thicknesses allow Hammer mill screens to be optimized for specific ore types and processing stages. For instance, finer perforations in a perforated sheet can enhance filtration accuracy in slurry separation, while larger openings may prioritize throughput in primary crushing applications.

Advanced laser-cutting technology ensures uniformity in hole geometry, which is crucial for maintaining consistent flow rates and preventing material buildup. In wet environments, such as hydrometallurgical plants, the smooth edges of laser-cut perforated screen plates reduce friction and wear, further prolonging screen life. Moreover, the ability to reinforce panels with additional framing or coatings adds versatility, enabling these screens to withstand high-impact loads or abrasive ore particles.

Our engineering team collaborates closely with clients to design perforated sheets that align with their unique operational challenges. From gold mines in South America to coal processing plants in Australia, our solutions are tailored to deliver unmatched performance, ensuring that every screen integrates seamlessly into existing workflows.

Stainless Steel Screens in Action Across Continents

The demand for durable perforated steel panels spans industries and geographies. In Africa’s copper belt, Hammer mill screens crafted from stainless steel have revolutionized ore grinding processes, reducing replacement cycles by over 50% compared to conventional screens. Similarly, in Southeast Asia’s tin mining sector, perforated screen plates resistant to acidic runoff have slashed operational costs while improving recovery rates.

North American shale gas operations rely on stainless steel perforated sheets for proppant sorting, where screens must endure high-pressure, saline-rich environments. Even in Europe’s stringent industrial ecosystems, our screens meet both performance and environmental compliance standards, proving that innovation and sustainability can coexist.

Exporting to over 40 countries, our perforated steel panels have become synonymous with reliability. Clients appreciate not just the product quality but also our commitment to after-sales support, ensuring that screens perform optimally throughout their lifecycle.

While stainless steel perforated screen plates are inherently robust, proper maintenance amplifies their longevity. Regular cleaning to remove ore residues prevents clogging and maintains airflow or liquid permeability. In highly abrasive settings, periodic inspections help identify early signs of wear, allowing timely repairs or replacements before failures occur.

For Hammer mill screens exposed to cyclical loading, stress-relieving treatments during manufacturing can mitigate metal fatigue. Additionally, selecting the right grade of stainless steel—such as 304 for general use or 316 for chloride-heavy environments—ensures that perforated sheets remain functional even under extreme conditions.

Our technical guides and on-site training programs empower clients to maximize screen lifespan. By adopting best practices, industries can transform their perforated steel panels from consumable components into long-term assets.

Stainless Steel Perforated Plate Screens for Corrosive Ore Environments FAQs

How do perforated steel panels handle extreme humidity in tropical mines?

Stainless steel’s corrosion-resistant properties make perforated screen plates ideal for tropical climates. The material’s chromium layer prevents rust formation, ensuring consistent performance even in 90% humidity.

Can Hammer mill screens be reused after wear?

Yes! Minor wear can often be repaired via welding or reshaping. For severe damage, recycling stainless steel perforated sheets is eco-friendly and cost-effective.

Are perforated sheets safe for filtering drinking water?

Absolutely. Food-grade stainless steel is non-reactive and safe for water filtration, provided the perforated steel panels are cleaned and installed correctly.

Do perforated screen plates require special storage?

Store panels in dry, ventilated areas to prevent moisture buildup. Stacking them horizontally with protective spacers avoids deformation.

How do I choose between different perforated sheet hole shapes?

Round holes suit general screening, while slotted patterns excel in directional flow. Consult our team to match hole geometry to your ore type.

Invest in stainless steel perforated steel panels that redefine durability. With a presence in 40+ countries, we deliver tailored solutions for your toughest challenges. Visit https://www.mutoscreen.com/ to explore our catalog or request a custom quote. Transform your ore processing—contact us now!