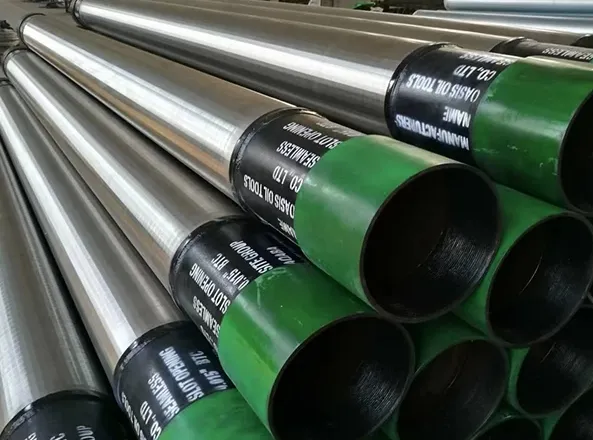

When sourcing well screens for sale, durability and adaptability are non-negotiable, especially in corrosive or physically demanding conditions. A well screen acts as the first line of defense against sediment, debris, and chemical degradation, ensuring long-term functionality for water extraction systems. For industries operating in harsh environments—whether in mining, agriculture, or municipal water supply—the choice of well screen pipe directly impacts operational efficiency and maintenance costs. This article explores the critical factors that define a premium water well screen, focusing on material innovation, structural design, and real-world performance.

Well Screen Materials Engineered for Corrosion Resistance

The foundation of a reliable well screen lies in its material composition. In corrosive environments, such as coastal regions or areas with high mineral content in groundwater, standard materials like mild steel or basic polymers quickly deteriorate. Premium well screen pipes leverage advanced alloys such as 316L stainless steel or duplex stainless steel, which offer exceptional resistance to chloride-induced pitting and crevice corrosion. These materials are further enhanced through precision manufacturing processes, ensuring uniform grain structure and eliminating weak points that could compromise integrity.

For applications requiring lightweight yet robust solutions, high-density polyethylene (HDPE) water well screens have gained prominence. HDPE’s innate resistance to chemical reactions—particularly in acidic or alkaline conditions—makes it ideal for industrial wastewater management or agricultural irrigation systems. Additionally, composite materials combining fiberglass-reinforced polymers (FRP) with corrosion-resistant coatings are increasingly used in offshore oil and gas operations, where saltwater exposure accelerates wear.

Protective Coatings Extend the Lifespan of Well Screens

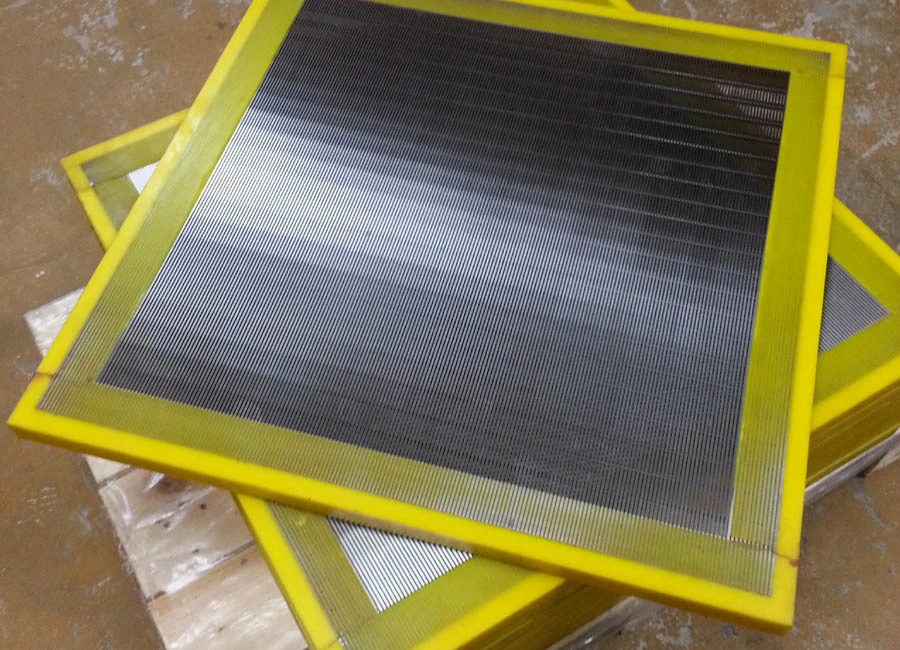

Beyond base materials, specialized coatings play a pivotal role in enhancing the durability of well screens for sale. Epoxy coatings, for instance, create a non-porous barrier that shields the well screen pipe from abrasive particles and chemical interactions. These coatings are applied using electrostatic spraying techniques, ensuring even coverage across complex geometries, including slotted or wire-wrapped designs.

In geothermal or high-temperature environments, ceramic-based coatings are employed to withstand thermal cycling and scaling. For water well screens exposed to bacterial growth—common in organic-rich groundwater—antimicrobial coatings infused with silver ions inhibit biofilm formation, preventing clogging and maintaining flow rates. Such innovations not only prolong service life but also reduce the frequency of maintenance interventions, a critical advantage in remote or hard-to-access installations.

Well Screen:Robust Design Adaptations for Extreme Conditions

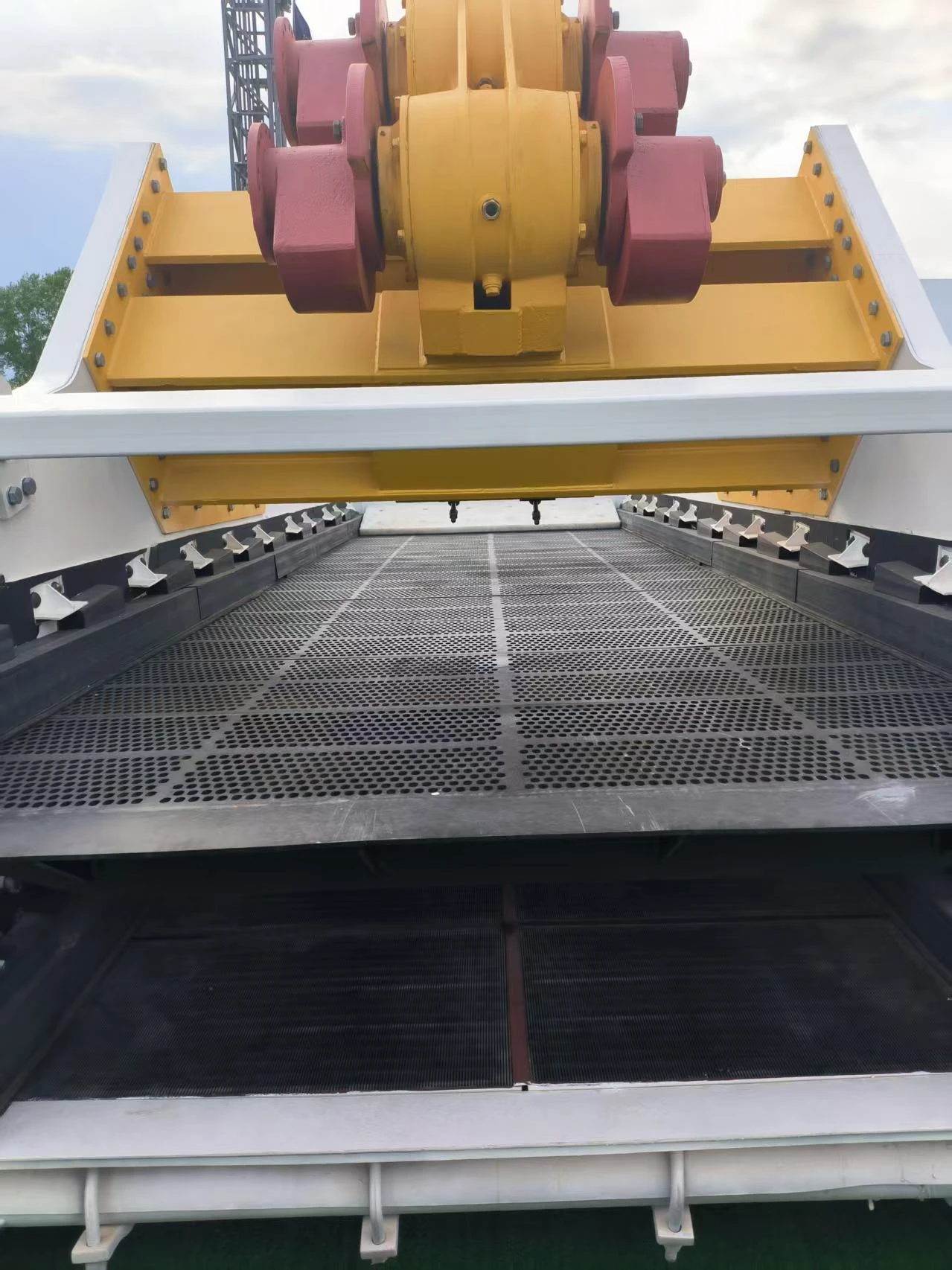

A high-quality well screen must balance filtration efficiency with structural resilience. In sandy or gravel-heavy aquifers, wedge-wire screens with V-shaped wire profiles excel at preventing particle ingress while maximizing open area for water flow. For environments with high turbidity or fluctuating water tables, telescopic well screen pipe designs allow adjustable lengths, adapting to dynamic subsurface conditions without requiring replacement.

In seismic zones or areas prone to ground shifting, helical support ribs integrated into the water well screen reinforce the structure against lateral forces. Similarly, screens deployed in freezing climates incorporate expansion joints to accommodate ice formation, preventing cracks or deformation. These design features ensure consistent performance across diverse terrains, from arid deserts to tropical wetlands.

Global Applications of Durable Well Screens

Our well screens for sale are trusted in over 40 countries, addressing unique challenges in varied climates. In Southeast Asia’s monsoon-prone regions, our corrosion-resistant well screen pipes withstand prolonged submersion in acidic rainwater. African mining operations rely on our abrasion-resistant designs to filter silt-laden water from deep boreholes. European municipalities utilize our antimicrobial water well screens to maintain potable water quality in limestone aquifers.

These global success stories underscore our commitment to customization. Whether tailoring slot sizes for specific sediment profiles or developing hybrid materials for extreme pH levels, we deliver solutions that align with local environmental and regulatory demands.

FAQs: High-Quality Well Screens for Harsh Environments

How do I choose the right well screen for coastal areas?

Coastal environments demand well screens with high chloride resistance. Stainless steel alloys or HDPE screens with epoxy coatings are optimal, as they prevent saltwater corrosion and barnacle buildup.

Can a well screen pipe handle high sediment loads?

Yes. Wedge-wire or louvered well screen pipes with reinforced support ribs are designed to manage heavy sediment while maintaining flow efficiency. Regular flushing can further mitigate clogging.

Are water well screens suitable for acidic groundwater?

Absolutely. HDPE or FRP water well screens with chemical-resistant coatings are ideal for acidic conditions, ensuring longevity without metal leaching.

What maintenance does a well screen require in harsh climates?

Minimal maintenance is needed if the screen is correctly specified. Annual inspections for abrasion or coating wear are recommended, along with periodic flushing to remove debris.

How do I procure custom well screens for unique projects?

Contact our team with your project’s environmental details—soil type, water chemistry, and flow requirements. We engineer well screens for sale tailored to your site’s challenges.

Investing in a high-quality well screen ensures decades of trouble-free operation, even in the most punishing conditions. With a global footprint spanning six continents, we combine material science expertise with localized engineering support. Explore our range of well screen pipes and water well screens today—visit https://www.mutoscreen.com/ to request a quote or consult our technical team for a customized solution.