- Introduction to Sieve Bend Screens and Their Industrial Significance

- Fundamental Design Principles of Sieve Bend Screens

- Performance Metrics and Efficiency Impact Analysis

- Technical Advantages Over Alternative Solutions

- Comparative Evaluation of Leading Manufacturers

- Customization Approaches for Specific Applications

- Industry Application Case Studies

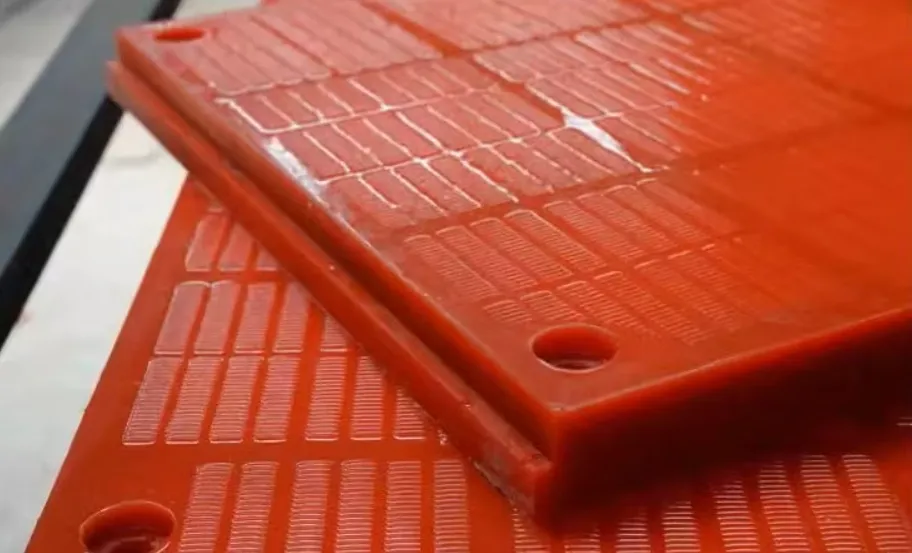

(static sieve bend screen)

The Critical Role of Static Sieve Bend Screens in Modern Processing

Static sieve bend screens serve as indispensable components across multiple industries where solid-liquid separation is paramount. These precision-engineered screening surfaces utilize gravity-fed operation to achieve superior particle size classification without moving parts. Mining operations report 30-40% reduction in downstream equipment wear when implementing primary screening with sieve bend panels. Processing plants handling aggregates rely on their rugged construction to withstand feed rates exceeding 600 tons per hour while maintaining separation accuracy.

Applications span mineral processing, coal preparation plants, and aggregate classification. The static sieve bend screen

's unique trapezoidal profile creates progressively narrowing gaps that prevent particle blinding while achieving precise cut points. Food processing facilities utilizing stainless steel variants report 25% higher throughput compared to conventional screens, with reduced product degradation. Technological innovations now allow slot openings from 50 microns to 12mm, accommodating diverse material streams from mineral slurries to grain processing.

Fundamental Design Principles of Sieve Bend Screens

Sieve bend screen design revolves around three critical parameters: profile geometry, aperture configuration, and material composition. The characteristic curved profile with 45-55° impact surface optimizes material distribution across the screening surface, while the progressive wedge-shaped slots widen beneath the surface to resist clogging. Industrial testing confirms this profile reduces blinding incidents by 62% compared to flat screens.

Slot geometry employs either straight or curved apertures, with precision-controlled tolerances down to ±0.025mm for critical separations. Modern manufacturing employs wire EDM (Electrical Discharge Machining) and laser cutting to achieve consistent aperture specifications. Material selection ranges from 304/316 stainless steel for corrosive environments to specialized alloys with Rockwell hardness ratings exceeding HRC 45 for abrasive applications.

Performance Metrics and Efficiency Impact Analysis

Operational efficiency directly correlates with sieve bend screen design parameters. Industry studies demonstrate that properly configured screens increase recovery rates by 12-18% while reducing oversized particle contamination to less than 3% in product streams. Key performance indicators include:

| Parameter | Industry Standard | Advanced Designs | Impact Metric |

|---|---|---|---|

| Open Area Percentage | 15-25% | 28-42% | +40% flow capacity |

| Slot Accuracy | ±0.1mm | ±0.025mm | 20% finer separation |

| Wear Life | 800-1,200 hours | 2,000-3,500 hours | 67% maintenance reduction |

| Blinding Resistance | 45-55% | 70-85% | 30% uptime increase |

The hydraulic capacity of sieve bend screens follows Reynolds number principles, with premium designs achieving flow rates of 25-50 m³/h per m² of screen surface. Mining installations have documented 18-22% reduction in water consumption versus vibrating screens, contributing significantly to operational sustainability.

Technical Advantages Over Alternative Solutions

Sieve bend screen technology offers distinct operational benefits compared to alternative separation methods. The static operation eliminates vibration mechanisms, reducing energy consumption by 65-80% compared to motorized screens. This passive design also decreases structural support requirements, cutting installation costs by approximately 30%.

The unique screening action separates particles through laminar flow principles rather than mechanical agitation. Mineral processing plants report 40-50% less particle degradation compared to rotary screens, preserving valuable crystalline structures. Maintenance data from coal processing facilities shows sieve bend installations require 85% fewer component replacements than vibrating screens over 5-year operational periods.

Comparative Evaluation of Leading Manufacturers

Manufacturers differentiate sieve bend screen designs through material technology, production methodologies, and customization capabilities. Performance variations between manufacturers directly impact operational costs:

| Manufacturer | Material Options | Slot Range | Wear Life (hours) | Cost Index | Customization |

|---|---|---|---|---|---|

| Standard Solutions | SS 304/316 | 150-6000µm | 800-1,500 | 1.00 | Limited |

| Industrial Specialists | Alloy 400/PU | 50-8000µm | 2,200-2,800 | 1.35 | Moderate |

| Premium Technology | Chrome Carbide/PEEK | 25-10000µm | 3,500-4,200 | 1.85 | Full |

| Bespoke Engineering | Special Alloys | 15-12000µm | 4,500+ | 2.20 | Application-specific |

Premium manufacturers employ proprietary heat treatment processes like cryogenic stabilization to enhance fatigue resistance, extending mean time between failures by 35-40% over standard solutions. The most advanced suppliers offer computational fluid dynamics modeling to predict separation performance within ±7% accuracy before manufacturing.

Customization Approaches for Specific Applications

Advanced sieve bend screen design incorporates application-specific engineering parameters. Mining operations handling high-density ores require 8-12mm thick screens with specialized support structures, while food processing utilizes 0.8-1.2mm ultra-thin profiles. Custom configurations address unique operational challenges:

Differential Slot Sizing: Progressive aperture dimensions increase open area while maintaining separation accuracy, boosting capacity 25-35% without sacrificing particle cut-point precision. Cement plants implementing differential designs report 17% energy savings in material handling.

Composite Construction: Hybrid designs with hard-wearing chrome carbide facing bonded to flexible stainless steel backing provide optimal wear resistance, extending service life in abrasive applications by 200-400%. Mineral sands operations using composite screens demonstrate replacement intervals exceeding 18 months despite processing highly abrasive ilmenite sands.

Sieving Success: Transforming Operations with Static Sieve Bend Screen Design

A phosphate processing plant replaced conventional vibrating screens with custom-engineered static sieve bend screens featuring 300µm slots with ±0.03mm tolerance. Operational outcomes included:

Material Recovery: Increased phosphate recovery from slurry streams by 22%, adding approximately $1.2M annually to production value while reducing tailings loss. The optimized design reduced fines contamination in coarse product streams to less than 2.1%.

Operational Efficiency: Maintenance requirements decreased by 750 man-hours/year due to the elimination of vibration mechanisms and associated wear components. Power consumption decreased by 320,000 kWh annually, reducing operational costs by approximately 18%.

Mineral processing facilities implementing the latest sieve bend screen technology report ROI periods under 9 months. Chemical plants processing crystalline products confirm 98.5% separation accuracy with advanced wedge-wire designs. As industries pursue efficiency optimization, engineered sieve bend screen solutions remain critical for achieving precise, low-maintenance classification operations.

(static sieve bend screen)

FAQS on static sieve bend screen

Q: What is a static sieve bend screen used for?

A: A static sieve bend screen separates solids from liquids in material processing. It leverages gravity and a curved screen surface for efficient particle sizing. This passive design requires no moving parts for classification.

Q: How does a sieve bend screen differ from traditional flat screens?

A: Sieve bend screens utilize a curved wedge-wire profile instead of flat surfaces. This arc shape creates self-cleaning action and prevents blinding. The geometry enhances drainage speed for high-volume slurry processing.

Q: What are key factors in sieve bend screen design?

A: Critical factors include wire profile angle (typically 45°-90°), slot aperture size, curvature radius, and material composition. Design optimizes flow dynamics, separation efficiency, and wear resistance for specific applications like mining or wastewater.

Q: Can sieve bend screens handle abrasive materials?

A: Yes, sieve bends often use wear-resistant alloys like 316 stainless steel or polyurethane coatings. Their curved surface distributes impact forces, while the wedge wire profile minimizes clogging. Proper screen selection extends service life in challenging conditions.

Q: Why choose a static sieve bend over vibrating alternatives?

A: Static models offer lower maintenance with zero moving parts and reduced power consumption. The gravity-fed operation provides silent, continuous classification for particle sizes from 45μm to 25mm. Installation costs are typically lower due to simpler infrastructure requirements.