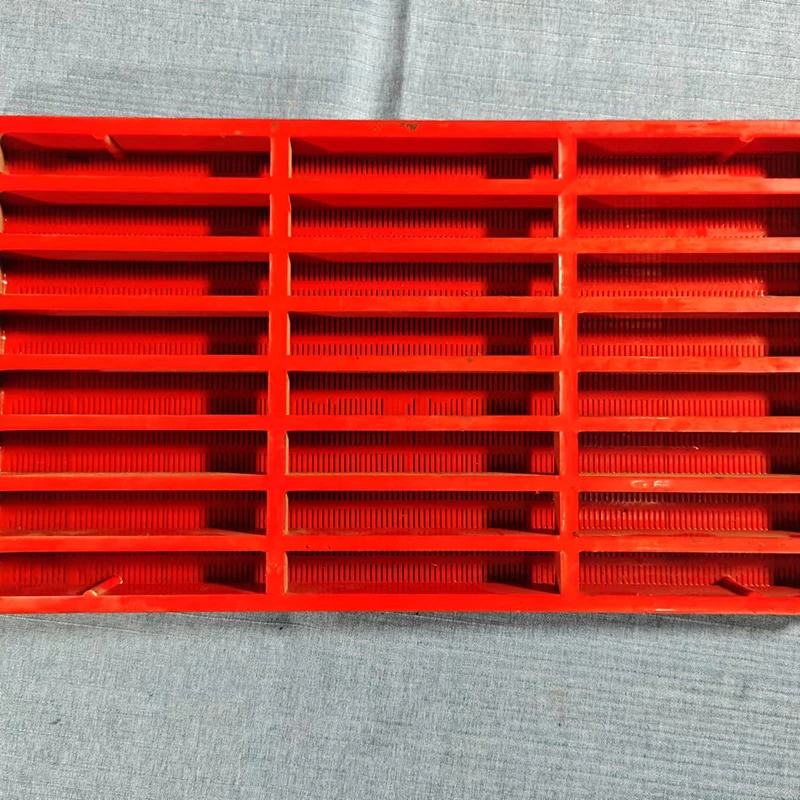

The polyurethane blind plate can be divided into feed blind plate and discharge blind plate. The feed blind plate is mainly used for the feed end of the screen, and the discharge blind plate is used for the discharge end of the screen.

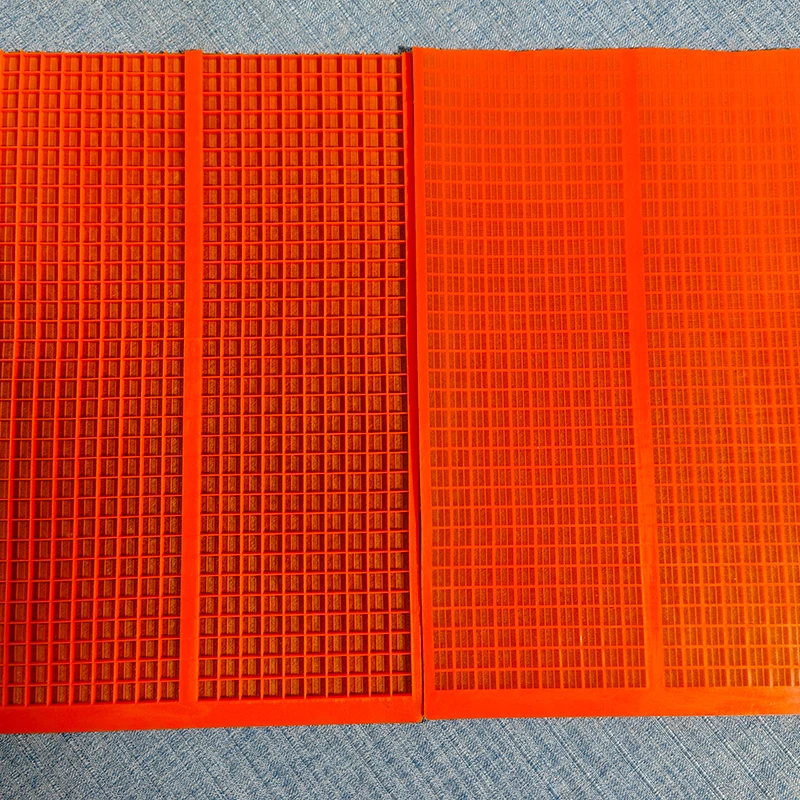

Wear resistance and corrosion resistance: The polyurethane material itself has excellent wear resistance and corrosion resistance.

Vibration absorption and noise reduction: polyurethane has good vibration absorption performance.

Self-cleaning ability: Due to its unique slit structure design, the polyurethane blind plate can effectively avoid screen clogging during the screening process and maintain the stability of the screening efficiency.

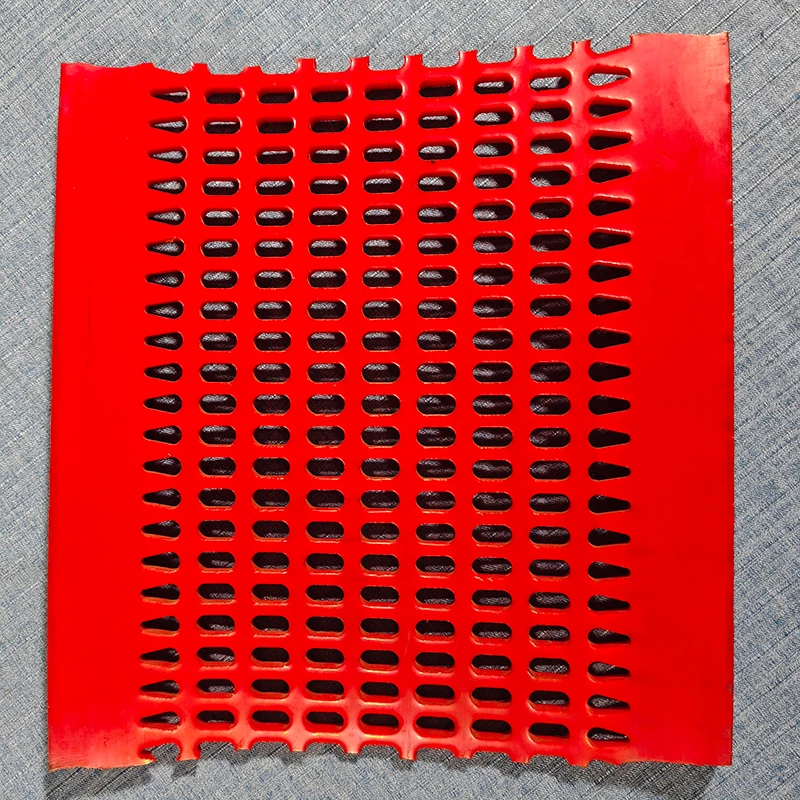

High opening rate: Compared with the traditional sieve plate, the opening rate of polyurethane blind plate is increased by more than 30%, the processing capacity per unit area is larger, and the production capacity can be increased by more than 40%.

The polyurethane blind plate is widely used in coal washing, mining and other related industries, for the separation of granular materials, dehydration, desliming and product classification.