The separation and purification of delicate crystals – from pharmaceuticals and fine chemicals to specialty salts and advanced materials – demand precision engineering to prevent damage during critical centrifugal processing. Fragile crystal structures are easily fractured or abraded under the immense forces generated within centrifuges, leading to product loss, reduced purity, and increased costs. Selecting the right centrifuge baskets is paramount, and wedge wire basket technology, pioneered by industrial screening experts like MUTO Wire Screen Co., Ltd., offers an unparalleled solution for gentle yet efficient handling. Founded in 2010 as Anping Zhanyuan Wire Mesh Factory in Anping County, China's "Capital of Wire Mesh," MUTO has evolved into a leading force in precision filtration. Officially registered as MUTO in 2018 following outstanding performance in mining screens and wedge wire baskets, the company expanded with branches in Pingdingshan, Henan (2019) and Jixi, Heilongjiang (2023). Holding 12 screen technology patents and 4 equipment patents, and recognized as a "National Science and Technology SME" (2023) and "High-Tech Enterprise" (2024), MUTO leverages its 2,500 m² wedge wire workshop and 2,000 m² equipment workshop, staffed by dozens of R&D specialists, to innovate robust solutions like their specialized centrifuge baskets for delicate crystal applications.

Engineering Gentle Containment with Wedge Wire Basket Design

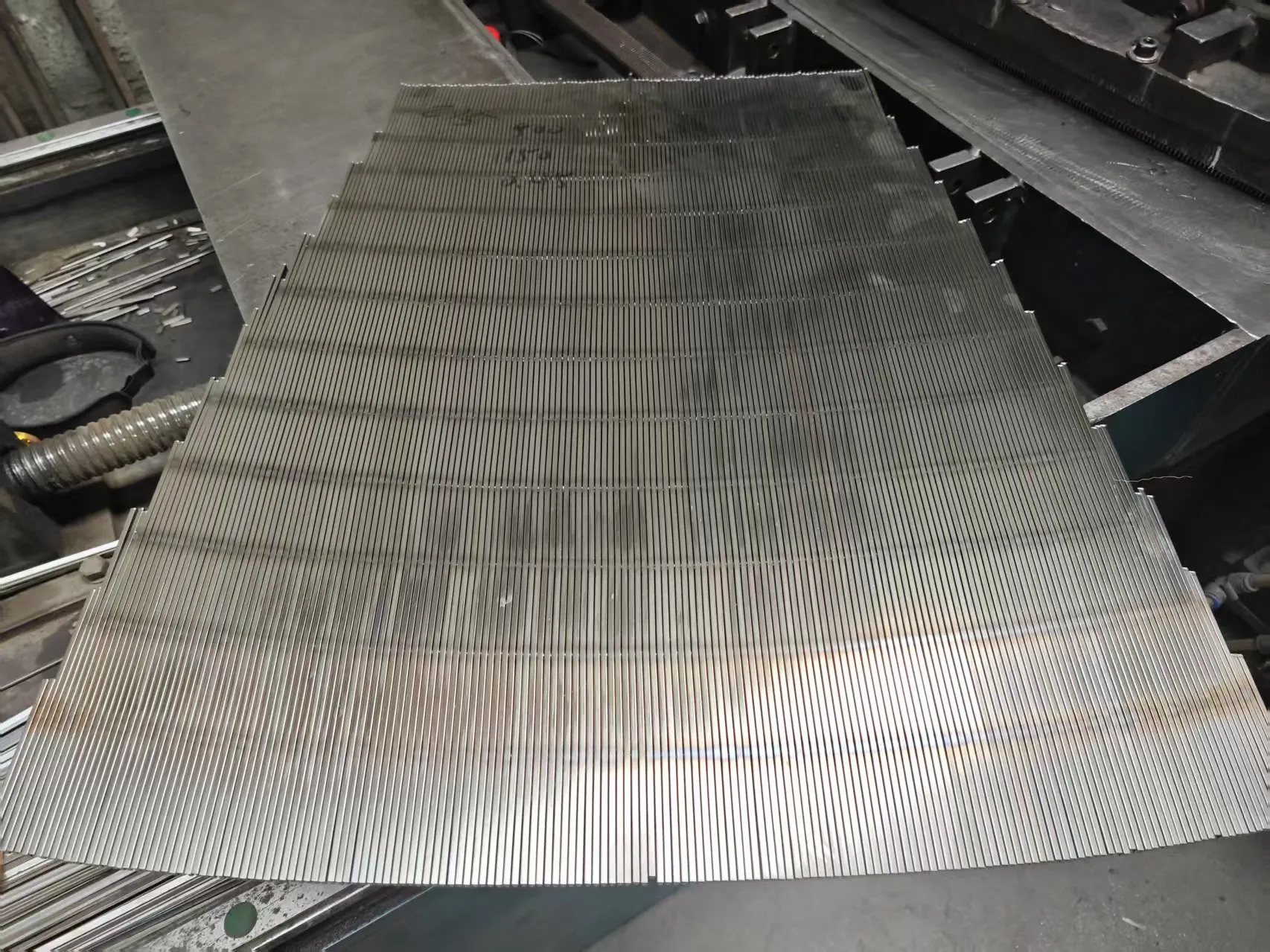

Traditional perforated plates or woven mesh baskets can create stress points and sharp edges detrimental to crystals. MUTO's wedge wire basket design fundamentally changes this dynamic. Each basket is constructed from precisely shaped V-profile wires welded perpendicularly onto robust support rods. This creates smooth, continuous inner surfaces with precisely controlled, uniform slots running the length of the basket. The absence of overlapping wires or burrs inherent in woven mesh significantly reduces the risk of crystal abrasion or snagging. The inherent strength of the welded structure allows for thinner profile wires compared to equivalent strength perforated plates, maximizing open screening area for faster dewatering while minimizing surface contact points that could damage crystals. This unique architecture, refined through MUTO's extensive experience in demanding mining and mineral processing applications, provides the gentle containment crucial for preserving crystal integrity.

Optimizing Centrifuge Baskets for Crystal Integrity

The core function of Centrifuge baskets is efficient solid-liquid separation. However, for delicate crystals, this must be achieved without compromising structure. MUTO optimizes several key factors:

- Slot Precision:Using state-of-the-art welding equipment developed in-house, MUTO achieves slot tolerances as fine as 0.02mm. This precision ensures only the desired mother liquor or wash liquid passes through, retaining even the smallest target crystals without allowing fines to clog the basket.

- Surface Finish:MUTO meticulously controls the welding process and employs post-weld finishing techniques to ensure the internal surface of the basket is exceptionally smooth. This minimizes friction and adhesion points where crystals could be damaged during loading, spinning, or unloading.

- Structural Rigidity:The robust welded wedge wire construction provides exceptional radial strength to withstand high G-forces without deflection. This prevents basket deformation that could crush crystals or create uneven flow paths leading to localized pressure points.

Material Selection for Corrosion Resistance in Wedge Wire Baskets

Crystal processing often involves corrosive mother liquors, wash solvents, or cleaning agents. The longevity of wedge wire baskets and the purity of the crystal product depend heavily on selecting the appropriate corrosion-resistant material. MUTO offers a comprehensive range of alloys tailored to specific chemical environments:

MUTO Centrifuge Basket Standard Parameters

|

Material |

Low carbon steel, high-manganese steel, stainless steel SS304, 304L, 316, 316L,2205 austenitic stainless steel, Hastelloy, etc. |

|

Wedge Wire (mm) |

Width: 0.75, 1.50, 1.80, 2.30, 3.00, 3.30, 3.70 |

|

Support Rod (mm) |

Width: 1.00, 1.80, 2.00, 3.00, 4.00, 5.00 |

|

Top/Bottom Diameter |

Up To 2.5 meters |

|

Length |

Up to 6 meters |

|

Slot size (mm) |

0.02, 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, ....., 3.00 |

|

Angle |

Other specifications available upon request |

From standard stainless steels (304, 304L, 316, 316L) for general applications to super duplex (2205) and high-performance alloys for extreme conditions, MUTO ensures material compatibility. This prevents contamination of sensitive crystals and extends the operational life of the basket significantly, even in aggressive chemical environments common in pharmaceutical or fine chemical production.

Applications and Scalability of Precision Centrifuge Baskets

Centrifuge baskets built with MUTO's wedge wire basket technology are ideally suited for industries where delicate crystal handling is paramount. The centrifugal baskets designed by our wedge wire screens are suitable for mechanical dewatering and concentration applications, suitable for salt production (especially high-purity flake or gourmet salts), mineral processing (fine crystals like lithium compounds), fine coal separation, sugar refining (sugar crystals), starch manufacturing, wastewater treatment (recovering valuable precipitates), and metal chip oil recovery in various industries. Crucially, MUTO's large-scale manufacturing capabilities, honed through supplying the demanding mining sector, ensure consistent, high-volume production. This scalability provides reliable supply chains for major industrial users requiring large quantities of specialized centrifuge baskets.

FAQs About Centrifuge Baskets for Delicate Crystals

What makes a wedge wire basket gentler on crystals than perforated baskets?

The continuous, smooth inner surface created by the V-profile wires eliminates burrs and sharp edges found on perforated plates. The uniform slot profile and minimized contact points significantly reduce abrasion and fracture during filling, spinning, and discharge.

How does slot size precision in Centrifuge baskets impact crystal yield?

Precise slot control, down to 0.02mm, ensures optimal retention of target crystal sizes while allowing efficient passage of mother liquor and fines. This maximizes product yield by preventing loss of valuable crystals through the basket slots and minimizes clogging from undersized particles.

Can wedge wire baskets handle the high G-forces required for efficient dewatering without damaging crystals?

Yes. The robust welded construction of MUTO's wedge wire baskets provides exceptional radial strength and rigidity. This prevents basket deflection under high centrifugal loads, ensuring even distribution of force and preventing localized crushing or deformation that could damage crystals.

What factors determine the best material choice for corrosive crystal processing in wedge wire baskets?

Material selection depends on the specific chemicals (solvents, acids, bases, salts) present in the mother liquor, wash solutions, and cleaning regimes. MUTO offers expertise in alloy selection, from standard stainless steels to high-performance alloys, to ensure corrosion resistance and prevent product contamination.

Are large diameter Centrifuge baskets using wedge wire technology feasible for industrial scale?

Absolutely. MUTO's manufacturing capabilities allow for the production of robust wedge wire baskets with diameters up to 2.5 meters and lengths up to 6 meters, specifically designed for large-scale industrial centrifuges handling high volumes of delicate crystalline products.

Safely processing delicate crystals within centrifuges hinges on the design and construction of the basket. MUTO Wire Screen Co., Ltd., leveraging its deep expertise in precision wedge wire basket technology developed for demanding industrial screening, provides the optimal solution. Their Centrifuge baskets feature smooth, non-abrasive surfaces, exceptionally precise slot control, robust welded construction for rigidity, and a wide range of corrosion-resistant materials. These attributes work synergistically to minimize crystal damage during loading, high-G spinning, and unloading, maximizing product yield, purity, and value. Backed by significant manufacturing scale and technical R&D capabilities, MUTO delivers reliable, high-performance wedge wire baskets tailored for the critical task of handling fragile crystalline materials efficiently and safely across diverse industries.