In the demanding world of mineral processing, efficient separation is paramount. Screening, a critical stage separating valuable ore from waste or classifying material by size, directly impacts throughput, product quality, and operational costs. When dealing with challenging materials – fine, wet, sticky, or easily blinding aggregates – conventional screens often fall short. This is where advanced screening technology, particularly flip flow screens, becomes indispensable. Leading the charge in providing high-performance, innovative screening solutions is MUTO Wire Screen Co., Ltd., a powerhouse born in the heart of China's wire mesh industry, Anping County.

MUTO's comprehensive portfolio addresses diverse industrial screening needs. They specialize in manufacturing a wide array of products, including wedge wire screens and filters, bend sieve screens, modular and tension polyurethane sieves, various woven steel mesh screens, perforated sheets, and innovative sieve-based components & parts. Crucially, they are also a leading manufacturer of flip flow screens – a technology central to optimizing efficiency in difficult screening applications prevalent in mining.

Mastering the Mechanics: How Flip Flop Screens Achieve Superior Separation

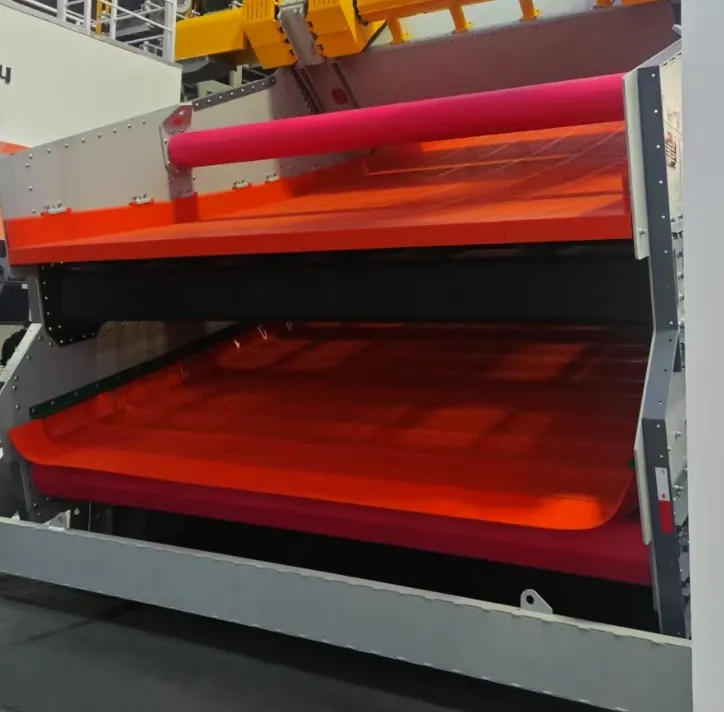

Often referred to interchangeably as flip flop screens or elastic mesh screens, flip flow screens represent a significant technological leap. Unlike rigid screens that rely primarily on vibration or linear motion, flip flow screens utilize flexible polyurethane screen panels tensioned within a robust frame. The core flip flow screen working principle involves imparting a dynamic, non-linear motion to these panels. Driven by twin unbalanced masses or exciters operating out-of-phase, the screen frame and the flexible panels move in a complex, high-acceleration pattern.

This motion creates a dramatic "flipping" or "flopping" action in the polyurethane panels. The material bed on the screen surface is subjected to intense acceleration and deceleration cycles. This dynamic action effectively prevents blinding and pegging – the primary culprits of inefficiency when screening sticky, wet, or fine materials like high-moisture raw coal, iron ore fines, limestone, or salt. The aggressive tossing and turning action keeps the apertures clear, ensures thorough stratification of the material bed, and promotes efficient passage of undersize particles, even at near-size separation points. The inherent elasticity of the polyurethane also contributes to its self-cleaning properties and extended service life under harsh conditions.

Engineering Excellence: Optimizing Flip Flow Screen Performance

Simply installing a flip flow screen isn't a guaranteed panacea; achieving peak efficiency requires careful optimization. This is where MUTO's extensive experience and technical expertise become invaluable. Optimization involves several key factors:

- Panel Design and Material:Selecting the correct polyurethane compound is critical. MUTO offers varying hardness levels (typically 50-80 Shore A) and formulations to balance wear resistance, flexibility, and cut resistance for specific applications. The aperture size, shape (square, rectangle, slot, circular), and panel thickness (ranging from 1mm to 20mm) must be precisely matched to the material characteristics (size distribution, moisture, abrasiveness) and the desired cut point.

- Motion Parameters:The intensity and frequency of the flip flow motion need fine-tuning. Adjusting the exciter speed, stroke, and phase angle allows operators to control the amplitude and aggressiveness of the panel movement, optimizing it for the specific material's flow characteristics and separation requirements.

- Deck Configuration and Tensioning:Proper tensioning of the polyurethane panels is paramount for consistent motion transmission and longevity. MUTO's expertise ensures panels are tensioned uniformly and securely within the robust screen frame. Multi-deck configurations can be employed for complex classification tasks.

- Application-Specific Design:MUTO understands that no two mining applications are identical. Their engineering team works closely with clients to design flip flow screens tailored to specific feed rates, material properties, moisture levels, and desired throughput and efficiency goals. This includes custom panel sizes beyond the standard 305mm width.

The table below summarizes key customizable parameters for MUTO's flip flow screen panels:

|

Panel size: |

305mm width or customized |

|

Aperture size: |

2~32mm (Ranges from coarse to fine, application-specific) |

|

Aperture shape: |

Square, Rectangle, Slot, Circular |

|

Panel Thickness: |

1 mm to 20 mm (Common range) |

|

Hardness: |

50-80A (Shore A) |

FAQs About Flip Flow Screens

What are the key differences between a flip flow screen and a flip flop screen?

The terms flip flow screen and flip flop screen are generally used interchangeably within the industry. Both refer to the same type of screening technology characterized by its use of flexible polyurethane screen panels subjected to a specific, high-acceleration motion that creates a dynamic "flipping" or "flopping" action. This action is key to handling difficult-to-screen materials. MUTO manufactures these screens under both commonly understood names.

How does the flip flow screen working principle combat material blinding?

The core flip flow screen working principle generates intense, high-frequency acceleration and deceleration cycles within the flexible polyurethane panels. This dynamic action violently agitates the material bed. Sticky particles clinging to the screen wires or near-size particles lodged in apertures (blinding or pegging) are forcefully dislodged by the aggressive panel movement. The constant flexing and snapping back of the polyurethane also contributes to a self-cleaning effect, maintaining open apertures for efficient undersize passage.

What types of mining materials are best suited for flip flow screens?

Flip flow screens excel with materials that are notoriously difficult for conventional screens. This includes fine particles (especially below 10mm), wet or high-moisture materials (like raw coal with surface moisture), sticky or clay-rich ores, materials prone to static cling, and feeds containing near-size particles. Their ability to prevent blinding makes them ideal for secondary and tertiary screening, scalping sticky feeds, and dewatering applications within mining circuits.

Can MUTO customize flip flow screen panels for specific mining applications?

Absolutely. MUTO specializes in customization to meet exact operational needs. Key customizable parameters include panel size (standard 305mm width or custom dimensions), aperture size (from 2mm to 32mm), aperture shape (square, rectangle, slot, circular), panel thickness (1mm to 20mm), and polyurethane hardness (50-80 Shore A). Their engineering team works with clients to define the optimal combination based on material characteristics, desired cut point, throughput requirements, and wear conditions.

What efficiency gains can a mining operation expect by switching to optimized flip flow screens?

Implementing properly optimized flip flop screens, particularly high-quality units like those manufactured by MUTO, can lead to significant efficiency improvements. These typically include substantially increased throughput capacity (often 2-3 times that of conventional screens on difficult materials), dramatically reduced screen blinding and associated downtime, improved screening accuracy leading to better product quality and less misplacement of fines, extended screen panel life due to reduced pegging wear and the material's cushioning effect, and lower overall operating costs per ton processed.

Optimizing screening efficiency is non-negotiable in modern mining, especially when processing challenging, fine, wet, or sticky materials. Flip flow screens (or flip flop screens) have proven to be the superior technology for these demanding applications, thanks to their unique working principle that generates dynamic, self-cleaning panel motion. MUTO Wire Screen Co., Ltd., leveraging its origins in Anping County and its evolution into a nationally recognized High-Tech Enterprise, stands at the forefront of this technology. Through significant investment in R&D (evidenced by 16 patents), substantial manufacturing capabilities, and a deep understanding of mining screening challenges, MUTO designs and produces high-performance, customizable flip flow screens in large volumes. By focusing on optimizing panel design, polyurethane formulations, motion dynamics, and application-specific engineering, MUTO empowers mining operations to achieve higher throughput, reduced downtime, improved product quality, and lower operating costs, solidifying their position as a trusted partner for precision screening solutions.