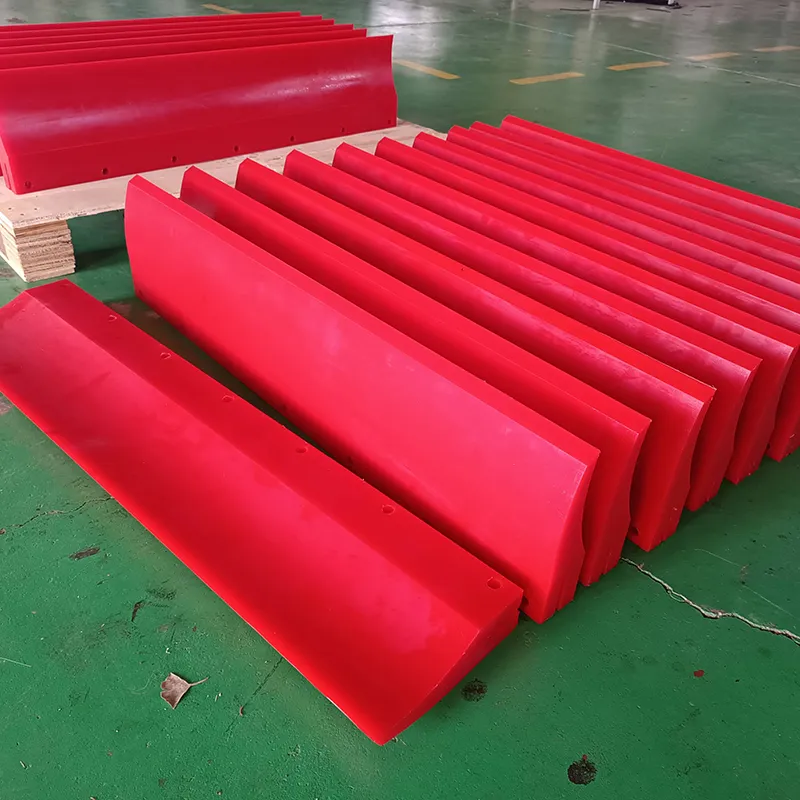

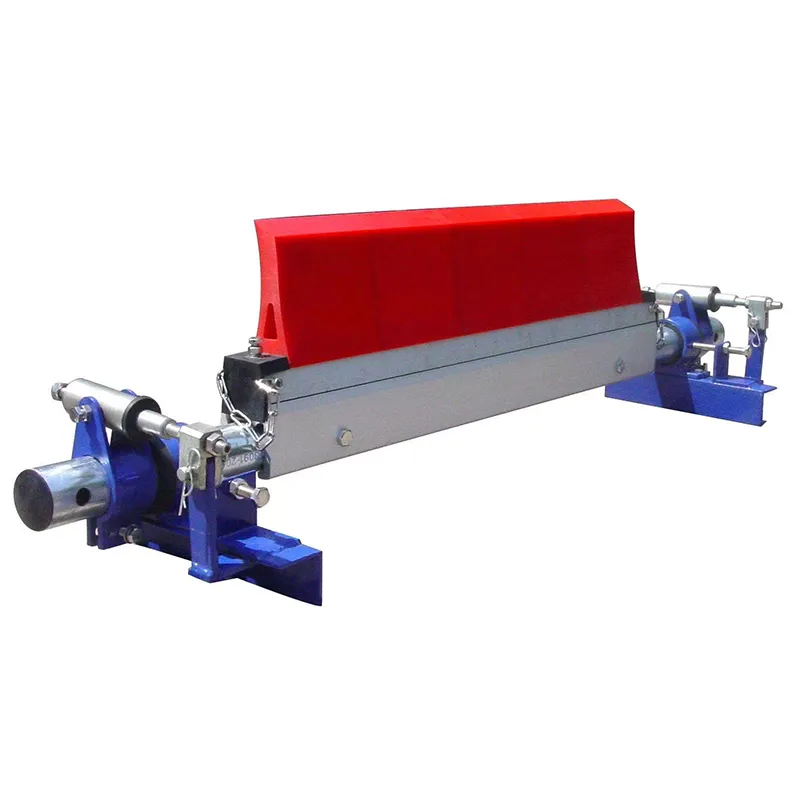

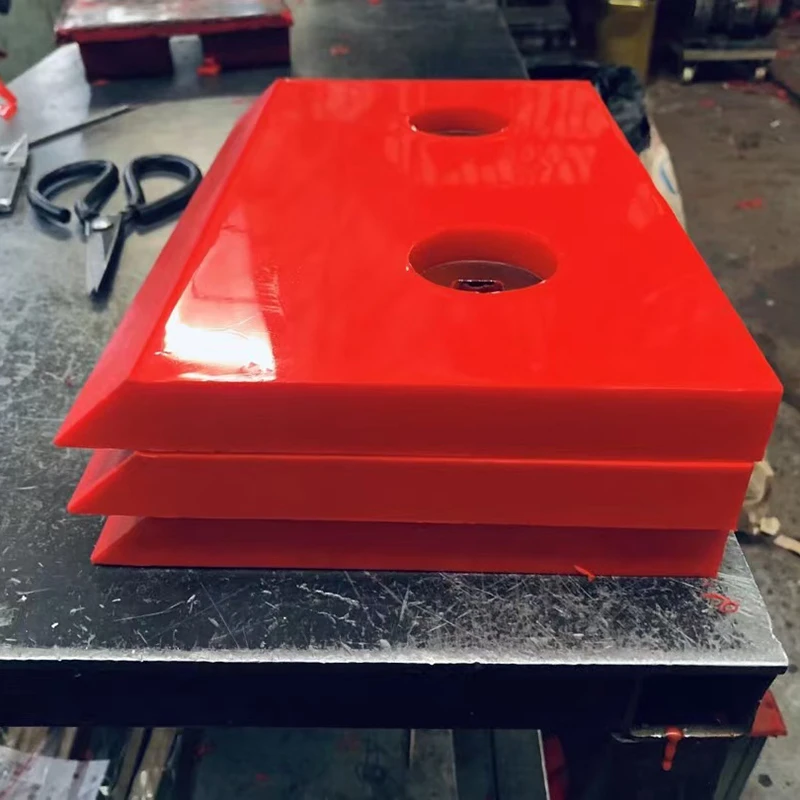

The polyurethane conveyor belt scraper is mainly composed of a scraper, a support, a regulating mechanism and other parts. The scraper is usually made of high-strength polyurethane material, which has excellent wear resistance, oil resistance and elasticity. The bracket is used to support the scraper and hold it in place. The adjusting mechanism can easily adjust the distance and pressure between the scraper and the material surface to adapt to different working environments and material characteristics.

* Low friction coefficient is good in corrosion resistance.

* Higher strength without damaging the belt, especially steel cord belt

* Flexibility and stiffness to adapt to belt profile

* Reach to food grade requirement, especial for food conveyor belt

* Fire retardant and anti static are available properties, especial for the mining industry

* Pre-slotted mounting holes reduce downtime and potential injury

The polyurethane conveyor belt scraper are widely used in various industrial fields, such as mines, ports, chemicals and so on. In the mining industry, it can be used to remove ore particles and dust from the conveyor belt; In the port industry, it can be used to remove debris and dirt on the cabin and dock; In the chemical industry, it can be used to remove residue and adhesion from pipes and equipment surfaces.