In the relentless pursuit of more durable and resilient smartphones, manufacturers face a constant adversary: environmental contamination. Dust, lint, oils, and moisture relentlessly assault device exteriors, particularly the screen. This accumulation not only degrades the user experience through smudges and reduced touch sensitivity but can also lead to long-term damage, potentially shortening the device's functional lifespan. Addressing this challenge requires innovative materials and design philosophies, often drawing inspiration from demanding industrial environments. This is where the expertise of companies like MUTO Wire Screen Co., Ltd. becomes pivotal. Founded in 2010 as Anping Zhanyuan Wire Mesh Factory in Anping County, China – globally recognized as "The Capital of Wire Mesh" – MUTO has evolved into a leading manufacturer specializing in precision screening solutions, particularly for mining and industrial filtration. Leveraging over a decade of experience, MUTO registered the "MUTO" brand in 2018, subsequently expanding with branches in Pingdingshan, Henan Province (2019) and Jixi, Heilongjiang Province (2023). Their commitment to innovation is underscored by 12 screen technology patents and 4 equipment patents, earning them recognition as a "National Science and Technology Small & Medium-Sized Enterprise" (2023) and a "High-Tech Enterprise" (2024). Operating from significant facilities – a 2500 square meter workshop for mining and wedge wire screen filter welding and a 2000 square meter workshop for screen welding equipment production, supported by dozens of R&D specialists – MUTO excels in producing a comprehensive range including wedge wire screens and filters, bend sieve screens, modular and tension polyurethane sieves, woven steel mesh screens, perforated sheets, and specialized welding machinery. It is from this robust foundation in industrial sieves that the potential of self cleaning screen technology for enhancing smartphone longevity emerges.

The Fundamental Advantages of Self Cleaning Screen Technology

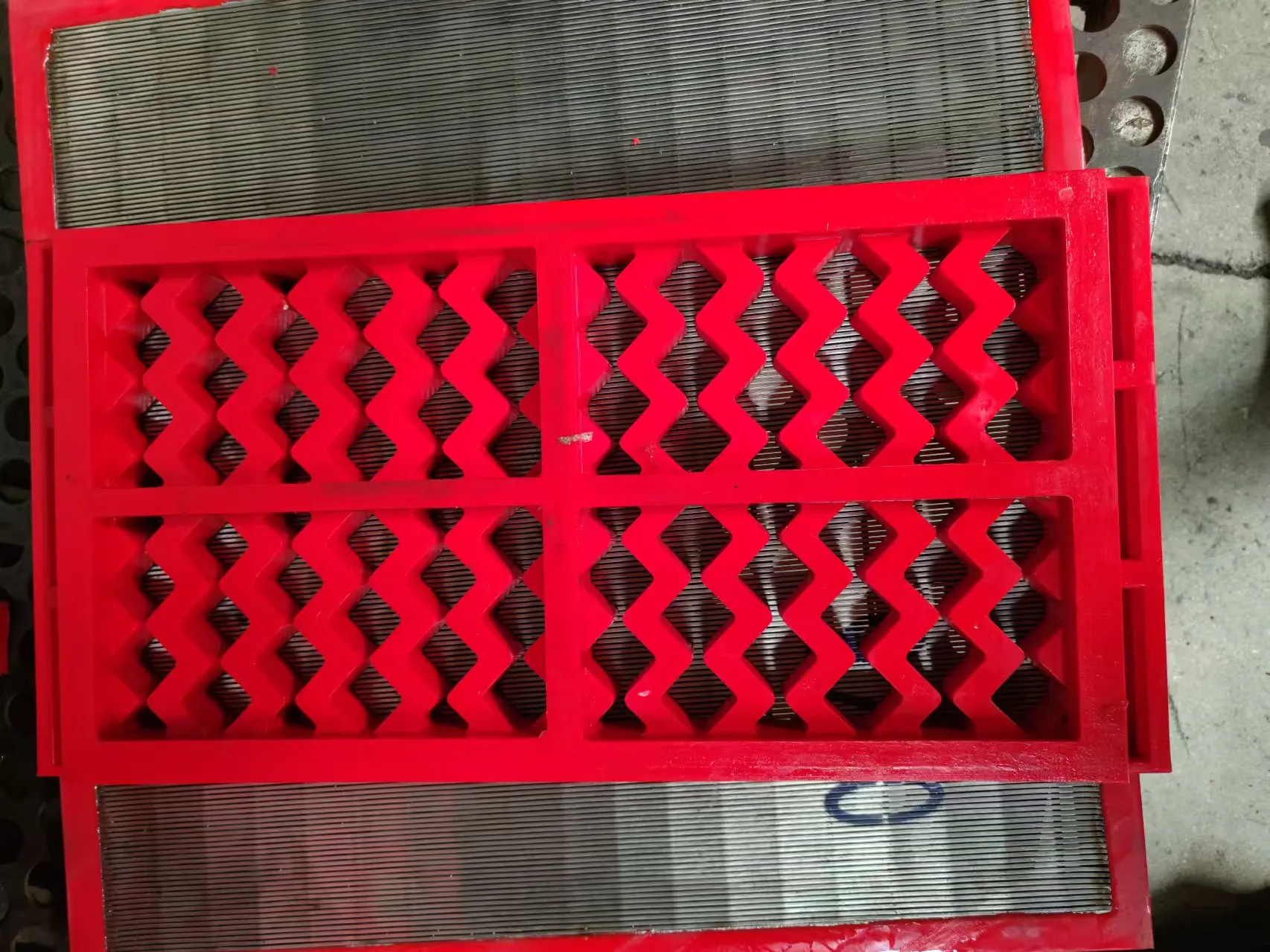

A self cleaning screen, also known as an anti-clogging screen, represents a significant leap from traditional flat or mesh protectors. Fundamentally, it is a specific type of screening media made with multiple individual metal wires (like the stainless steel MUTO specializes in) or advanced polyurethane material. The core principle lies in its geometry. Unlike flat surfaces where particles can settle and adhere, or standard meshes where particles can become lodged, self-cleaning designs incorporate specific profiles – such as the wedge wire structures MUTO manufactures for harsh mining applications – that minimize the surface area contact for debris. Particles encountering the screen tend to roll or slide off rather than stick. For smartphones, this translates directly to longevity. Reduced particulate accumulation means less abrasive grit is pressed against the screen surface during use or pocket storage, minimizing microscratches that can cloud the display over time. Furthermore, significantly less frequent and less aggressive cleaning is required. Constant wiping, especially with improper cloths or cleaners, gradually degrades oleophobic coatings and can introduce scratches. By inherently repelling contaminants, a self cleaning screen preserves these protective layers and the pristine clarity of the underlying display for far longer, directly extending the device's usable life and maintaining its aesthetic appeal.

Material and Structural Innovations in Self Cleaning Screen Mesh

The effectiveness of a self cleaning screen mesh hinges critically on the materials used and the precision of its construction – areas where MUTO's industrial heritage provides a distinct advantage. Drawing from their expertise in high-wear applications like mining screens and polyurethane sieves, MUTO understands the demands placed on materials. For smartphone applications, the self cleaning screen mesh typically leverages high-grade stainless steel (like 316L known for corrosion resistance) or specialized, durable polyurethane compounds. MUTO's proficiency in welding wedge wire profiles and tensioning polyurethane modules ensures that the mesh structure maintains its precise geometry under stress. This structural integrity is vital. The individual wires or polyurethane elements must be consistently spaced and securely bonded to maintain the self-cleaning properties. Any deformation or weak point compromises the ability to shed debris. MUTO's investment in proprietary welding equipment and their focus on micron-level precision in their 2500 sqm wedge wire workshop translate directly into reliable self cleaning screen mesh production. The inherent strength and corrosion resistance of these materials, proven in far harsher environments than a smartphone will ever face, provide exceptional durability against daily impacts, flexing, and exposure to sweat or environmental elements, further bolstering the screen protector's lifespan and, by extension, the phone's longevity.

Protective Qualities of Self-cleaning Mesh Against Environmental Factors

Smartphones are exposed to a wide array of environmental challenges beyond simple dust. Moisture, humidity, salt spray, and even UV radiation can contribute to degradation. A well-designed self-cleaning mesh offers inherent advantages here. The open structure, inspired by MUTO's industrial filters and bend sieve screens, allows for better moisture dissipation compared to solid covers that can trap condensation. Certain polyurethane formulations used in MUTO's tension sieves naturally exhibit hydrophobic properties, actively repelling water and preventing droplet adhesion that can obscure vision or seep into device seams over time. The reduced surface contact area also minimizes the retention of corrosive agents like salt. Furthermore, the materials themselves are selected for environmental resilience. MUTO's stainless steel meshes resist oxidation, while their advanced polyurethanes are formulated to withstand UV degradation and temperature extremes without becoming brittle or discolored – a critical factor confirmed through rigorous testing in diverse climates, supported by their geographically dispersed branches in Jixi (cold) and Pingdingshan. By mitigating the ingress and corrosive effects of these environmental elements, the self-cleaning mesh protects not just the screen surface but also helps safeguard the phone's casing and underlying components from premature aging or corrosion-related failures.

Manufacturing Excellence Enabling Scalable Self Cleaning Screen Solutions

Translating innovative self cleaning screen concepts into mass-produced, reliable components for the global smartphone market requires significant manufacturing capability. MUTO's evolution from a wire mesh factory to a technologically advanced enterprise positions them uniquely. Their large-scale facilities – the 2500 sqm screen welding workshop and the dedicated 2000 sqm equipment production facility – are geared towards high-volume, precision manufacturing. Utilizing automated processes derived from their screen welding machinery expertise, MUTO can produce self cleaning screen panels with consistent quality and micron-level accuracy essential for smartphone integration. Their focus on "smart technology to create products," evidenced by their numerous patents and high-tech certifications, drives continuous improvement in production efficiency and defect reduction. Dozens of R&D members constantly refine materials, profiles, and manufacturing techniques. This scalability ensures that advanced self cleaning screen technology, born from industrial filtration, can be reliably produced in the vast quantities demanded by smartphone OEMs, making enhanced device longevity accessible on a global scale without compromising on quality or performance standards.

FAQs About Self Cleaning Screen Technology

How does a self cleaning screen physically prevent debris buildup?

The core mechanism lies in its specialized geometry, often based on wedge wire profiles or specific polyurethane structures. These designs feature slopes, curves, or minimized contact points that prevent particles from getting a firm grip. Gravity, device movement, and even light contact cause debris to roll or slide off the surface instead of adhering, significantly reducing accumulation.

What materials are typically used in high-performance self cleaning screen mesh?

The most common and effective materials are high-grade stainless steel (like 316L for its corrosion resistance and strength) and specialized, durable polyurethane compounds. These materials are chosen for their resilience, environmental resistance (to moisture, UV, temperature), and ability to be precision-formed into the necessary self-cleaning geometries.

Can a self-cleaning mesh protect against liquid damage as well as dust?

While not a waterproof seal, a well-designed self-cleaning mesh offers superior protection against liquids compared to flat protectors. Its open structure allows water to drain or evaporate more easily, and hydrophobic material treatments actively repel water droplets. This significantly reduces the risk of liquid pooling and potentially seeping into device seams over time, protecting against corrosion.

Does the self cleaning screen technology impact touchscreen sensitivity or display clarity?

When manufactured with precision, using high-transparency materials and optimal aperture sizing (as achieved through MUTO's advanced welding and forming techniques), a self cleaning screen has minimal impact on touch sensitivity or display clarity. The open area percentage is carefully engineered to maintain excellent touch responsiveness and visual fidelity.

Are self cleaning screen mesh designs customizable for different smartphone models?

Absolutely. Leveraging expertise in custom industrial sieves and filters, manufacturers like MUTO can tailor self cleaning screen mesh designs. This includes adjusting wire/polyurethane profile dimensions, aperture size and shape, curvature to match phone contours, and material selection to meet specific durability, transparency, and aesthetic requirements for any smartphone model.

The relentless accumulation of environmental contaminants poses a significant threat to smartphone longevity, primarily through screen degradation and the potential for internal damage. Self cleaning screen technology, derived from robust industrial filtration principles perfected by companies like MUTO Wire Screen Co., Ltd., offers a compelling solution. By utilizing specialized geometries – often wedge wire profiles or tensioned polyurethane structures – and high-performance materials like corrosion-resistant stainless steel or advanced polymers, these screens actively repel dust, moisture, and oils. This dramatically reduces abrasive wear, preserves protective coatings, minimizes the need for potentially damaging cleaning, and helps shield against environmental corrosion. MUTO's extensive background in precision mining screens, wedge wire filters, and polyurethane sieves, backed by significant R&D investment, patented technologies, and scalable manufacturing infrastructure in Anping County and beyond, positions them at the forefront of adapting this durable technology for consumer electronics. Integrating self cleaning screen mesh represents a tangible step towards building smartphones that not only look better for longer but also withstand the rigors of daily use more effectively, ultimately extending their functional lifespan and enhancing user satisfaction.