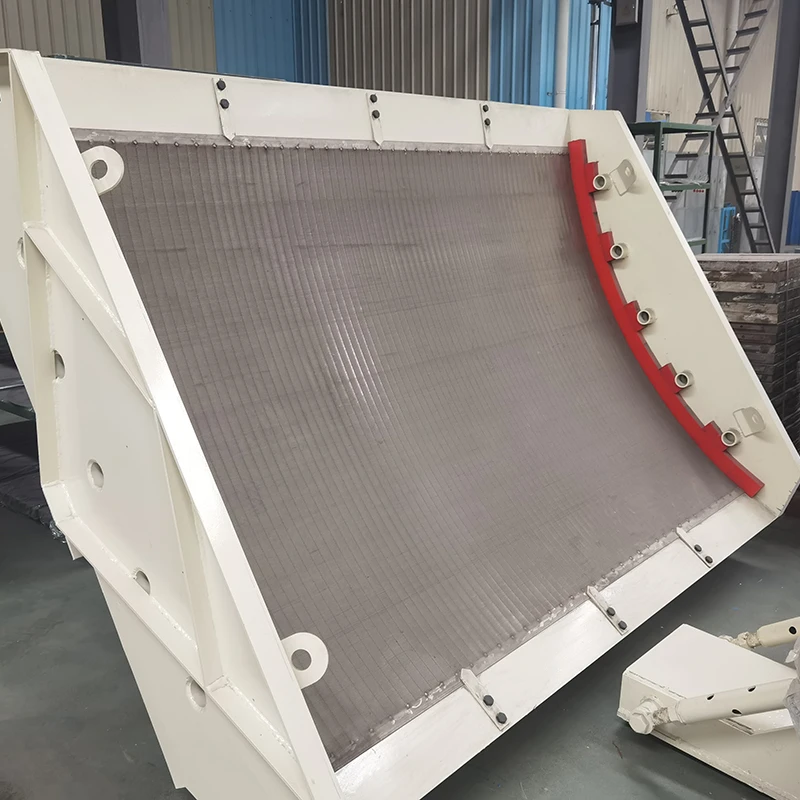

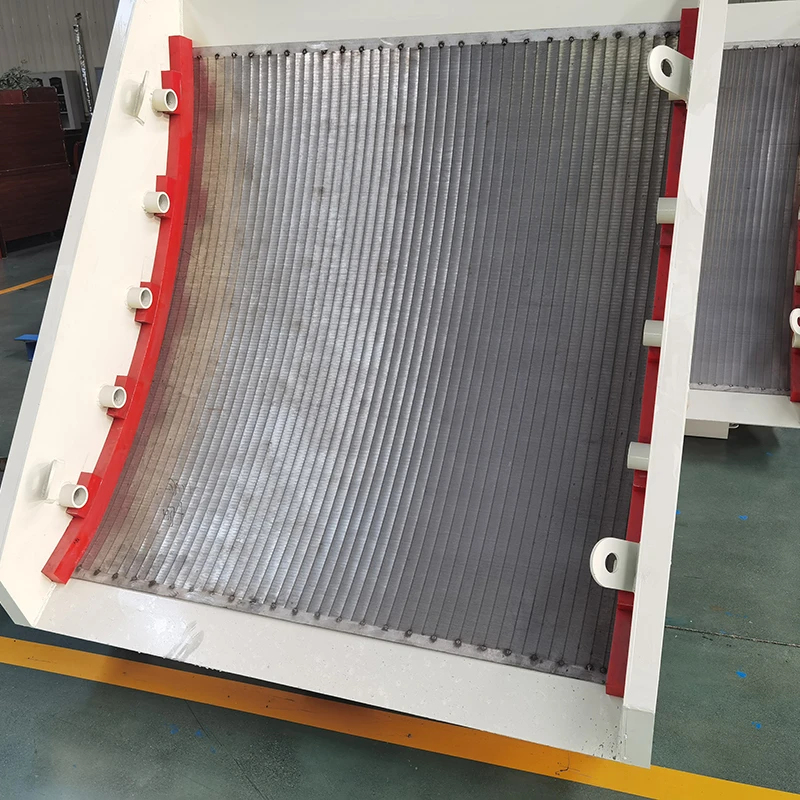

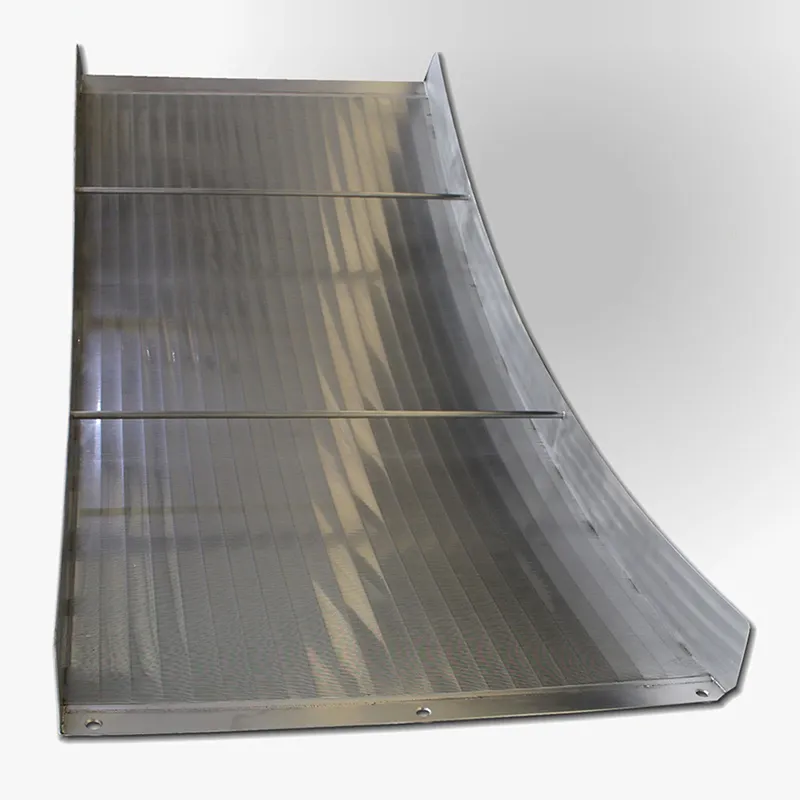

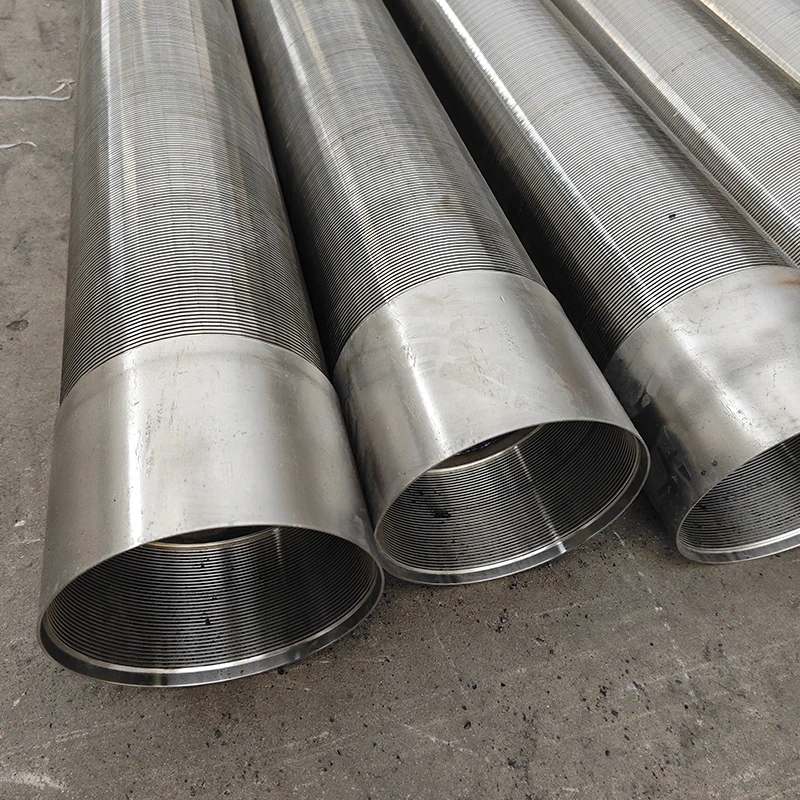

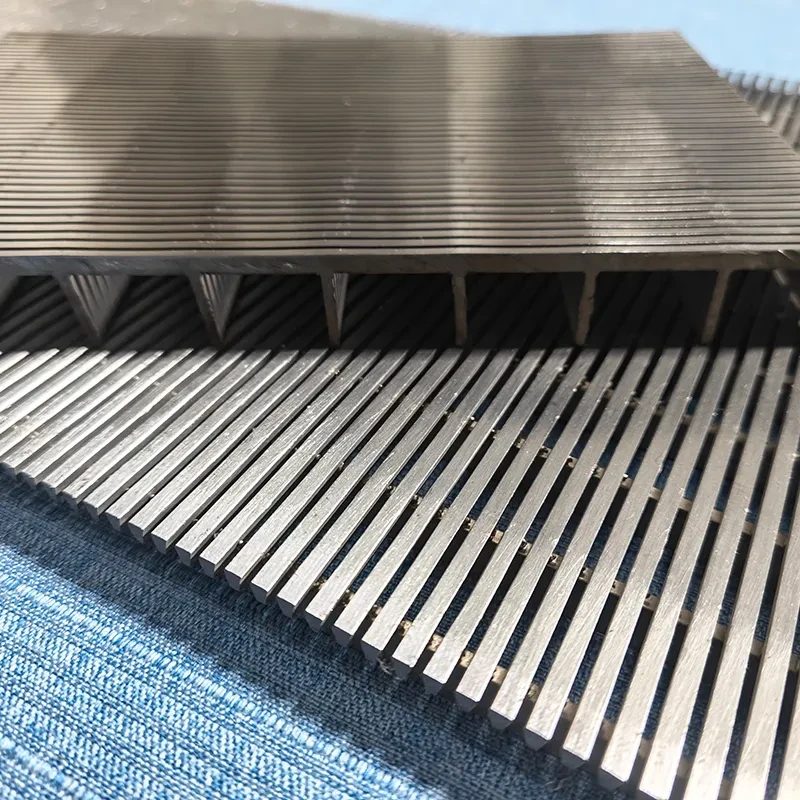

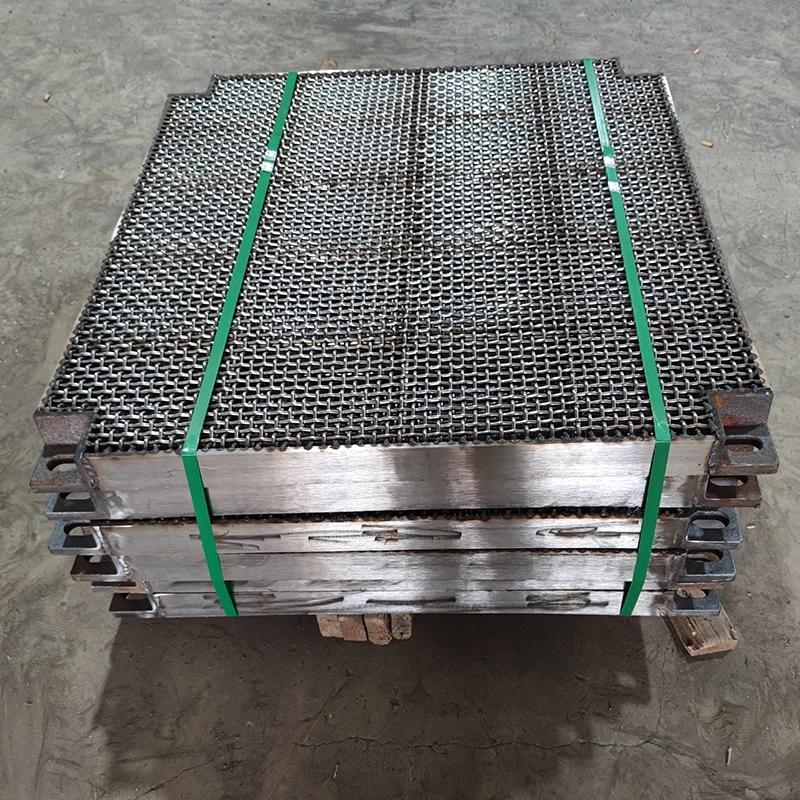

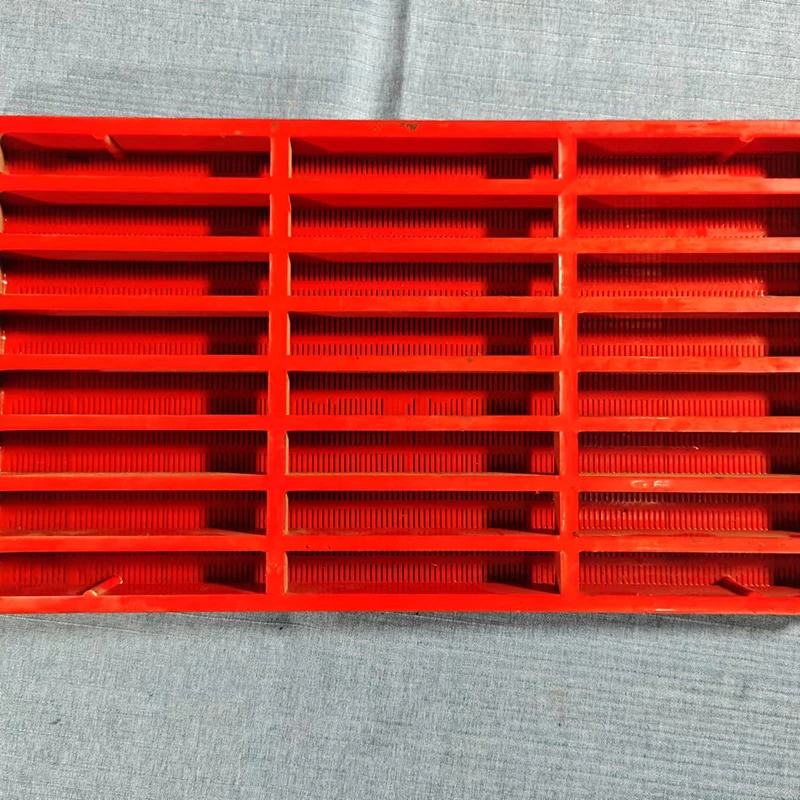

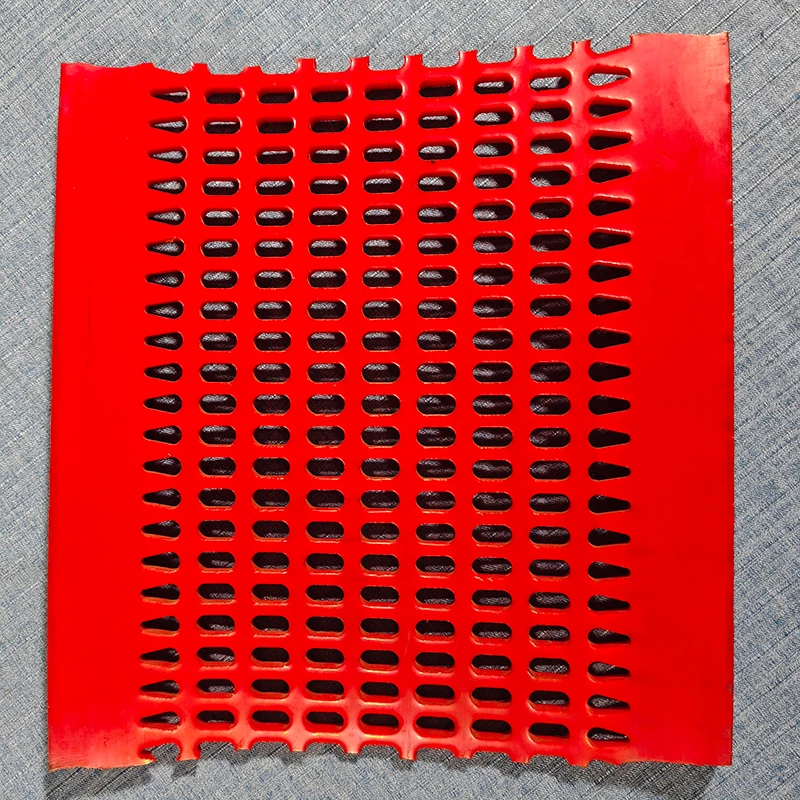

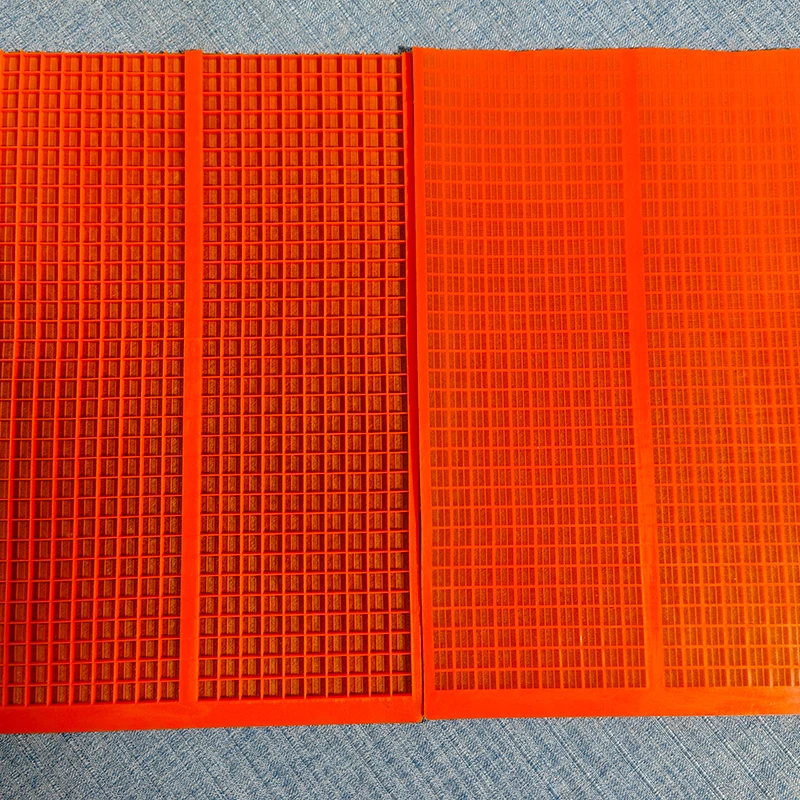

The sieve bend screens/ DSM screens, inclined screens, curved screens, slotted screens, and hydraulic grids. The wedge wire screen sieve bend screens are easy to penetrate, having good wear-resisting and corrosion resistance.

One of the standout features of the sieve bend screen is its ability to handle a wide range of materials, from fine powders to coarse aggregates, across diverse, industries such as mining, quarrying, recycling, and food processing.

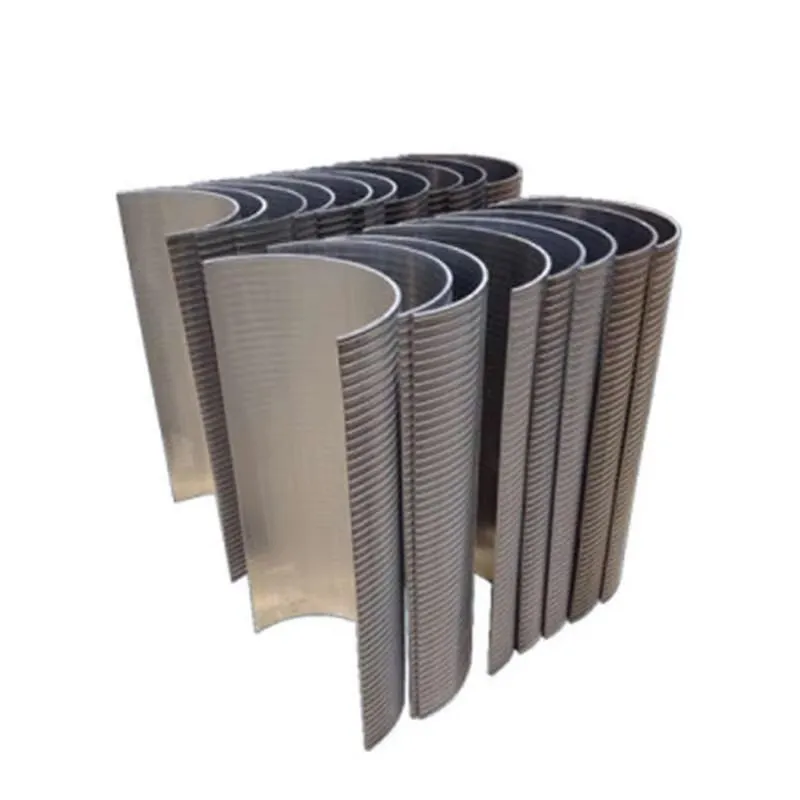

With Trapezoidal cross-section, even gap, stable welding quality, large opening area, long life time, high strength and high load capacity, it can be made into various shapes. The dimensions, wire diameter, slot and frame structure can be customized.

|

Angles |

45° |

60° |

120° |

||||||

|

Radius |

1018mm |

1527mm |

2036mm |

1018mm |

1527mm |

2036mm |

1018mm |

1527mm |

2036mm |

|

Arc Length |

800mm |

1200mm |

1600mm |

1066mm |

1600mm |

2132mm |

2132mm |

3198mm |

4264mm |

|

Width |

600-900-1000-1200-1500-1800-2000-2100-2200-2400-2700-3000mm or customized size |

||||||||

|

Slot Size |

0.25-1mm slot or customized |

||||||||

Wastewater treatment

Sea water desalination

Food processing

Water softening treatment

Mineral processing

pulp and paper production

Oil and chemical processing

Terminal filtration for petroleum products

Filtration for chemical acid and soda liquid

Alcohol and other organic solvents recycle filtration

Textile factory