Self-cleaning screen panels are designed to prevent the accumulation of fine particles in screening applications, ensuring efficient operation and reducing maintenance requirements.

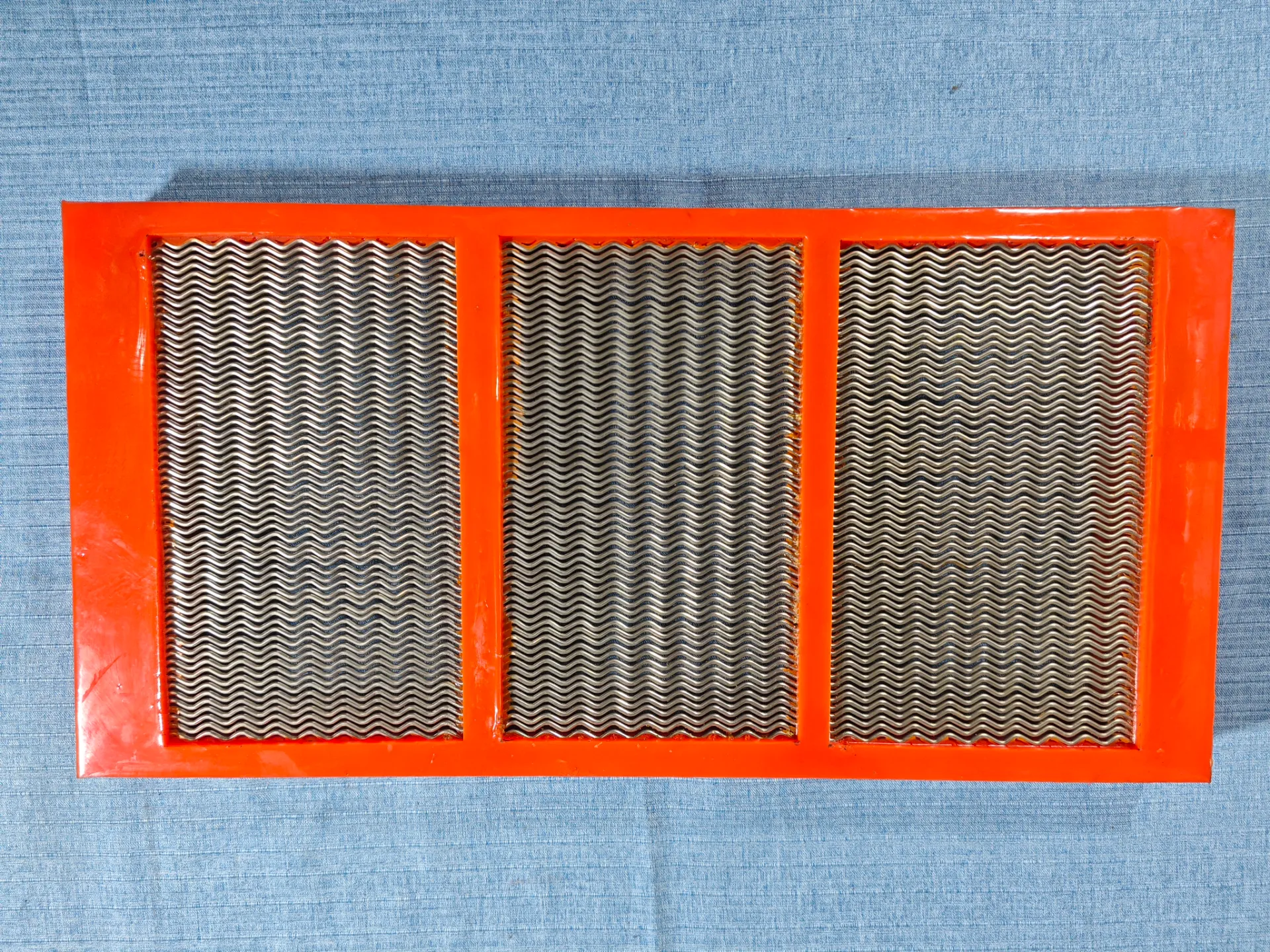

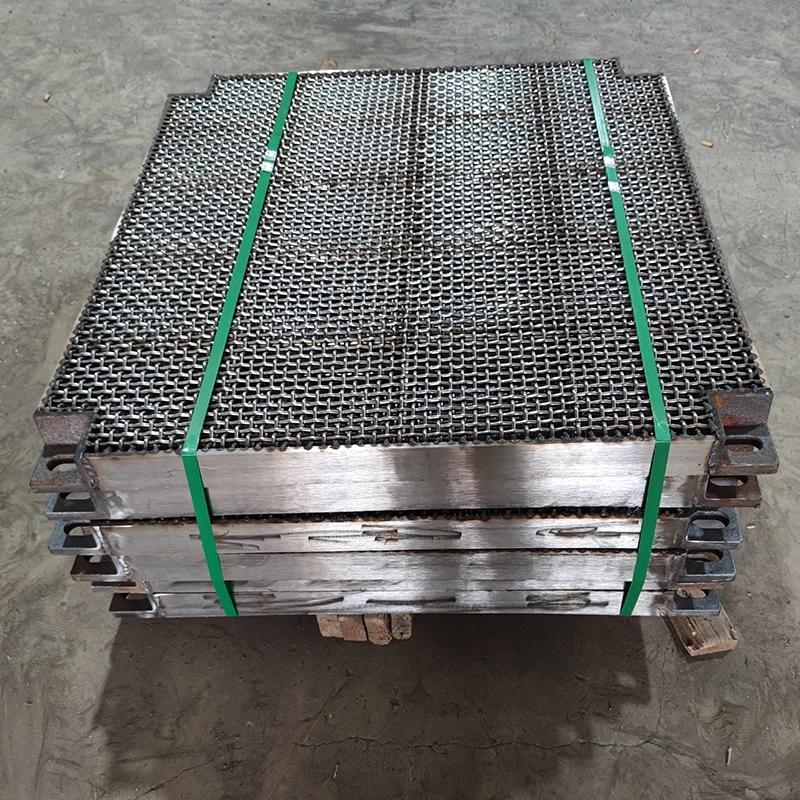

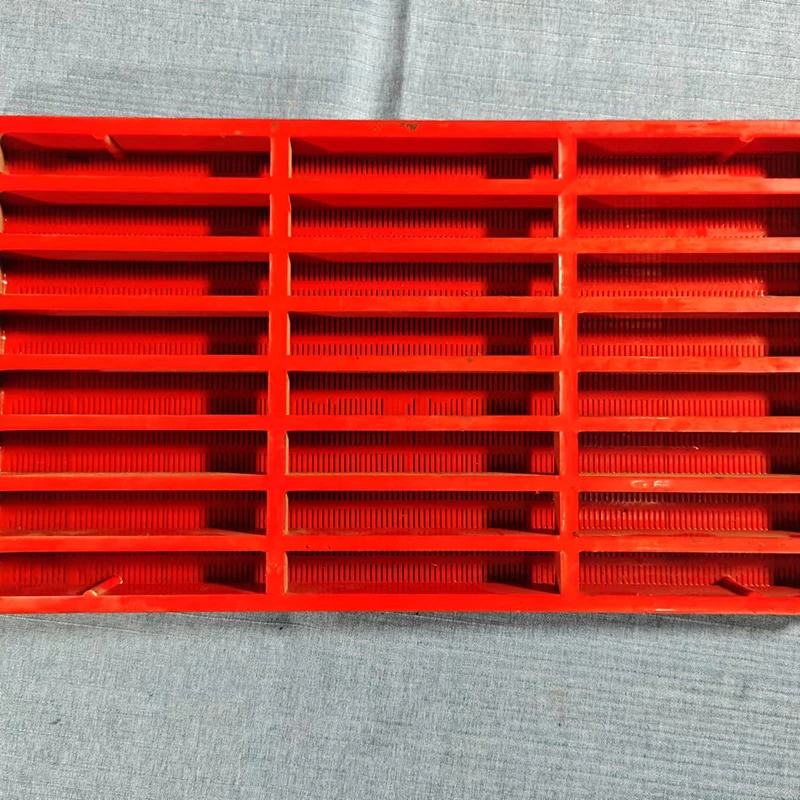

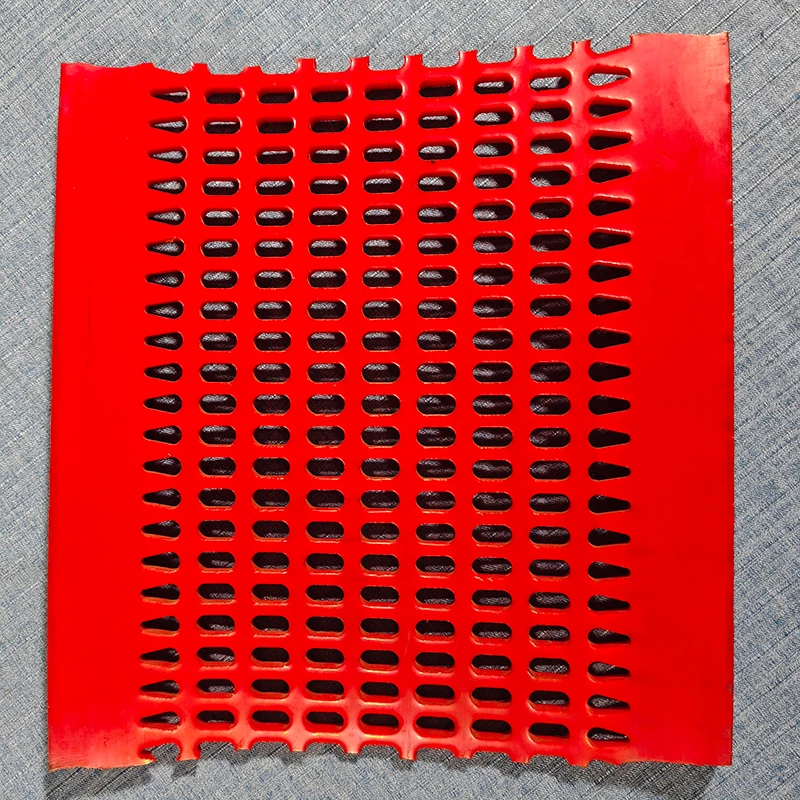

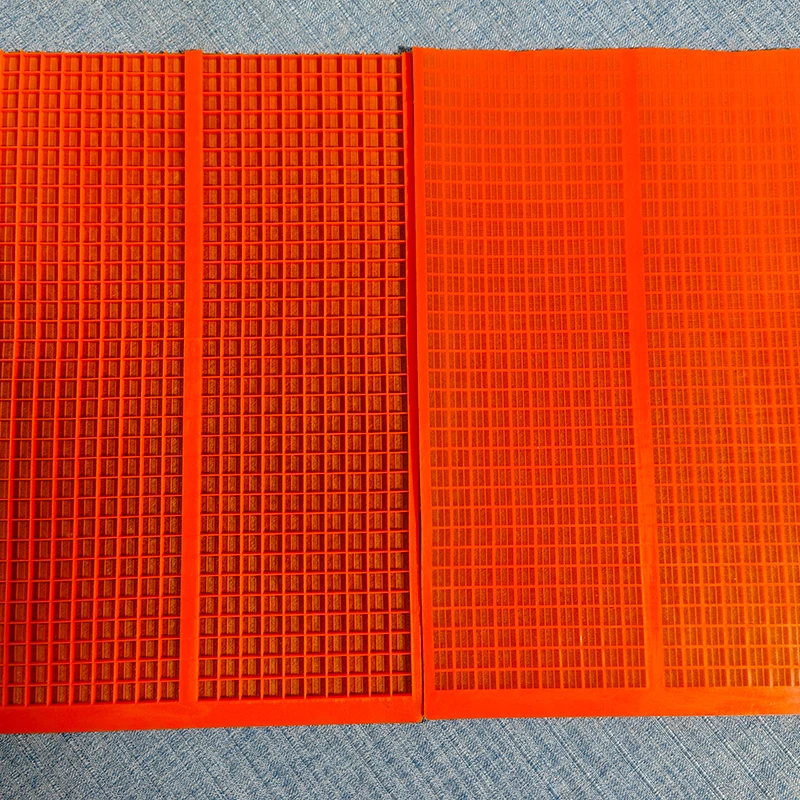

The self-cleaning screens are typically made from durable materials such as polyurethane, rubber, or stainless steel wires. These materials offer a balance of flexibility and strength, essential for the self-cleaning mechanism.

Reduced Plugging: The independent vibration effectively clears the mesh, minimizing the risk of clogging even with sticky or wet materials.

Increased Wear Life: With less strain on the screening surface, the self-cleaning screen boasts a significantly longer service life compared to conventional screens.

Enhanced Screen Efficiency: Improved throughput and finer separation accuracy lead to higher productivity and better end product quality.

Low Maintenance: The self-cleaning feature reduces the need for frequent cleaning and maintenance, saving time and operational costs.

Mining and quarry: used for grading and screening of ores.

Construction: used to remove oversized particles in the production of sand and gravel.

Food processing: used for screening and grading of food raw materials.

Chemical industry: used for screening of raw materials and products in the production of chemical products.

Recycling industry: used for sorting and recycling of waste materials.