-

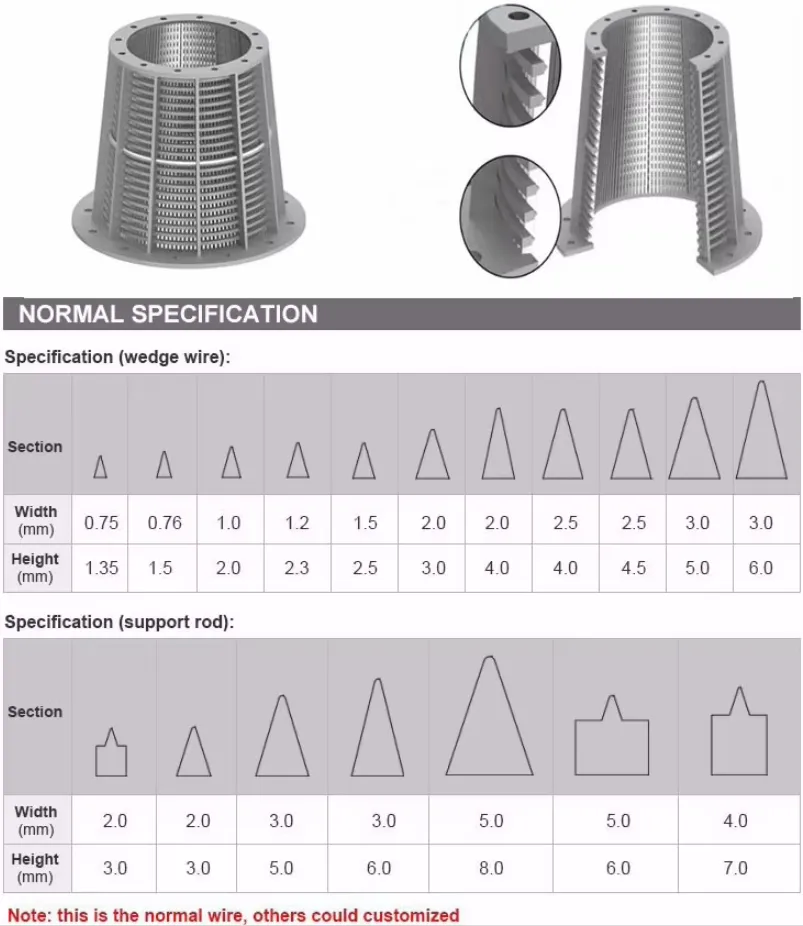

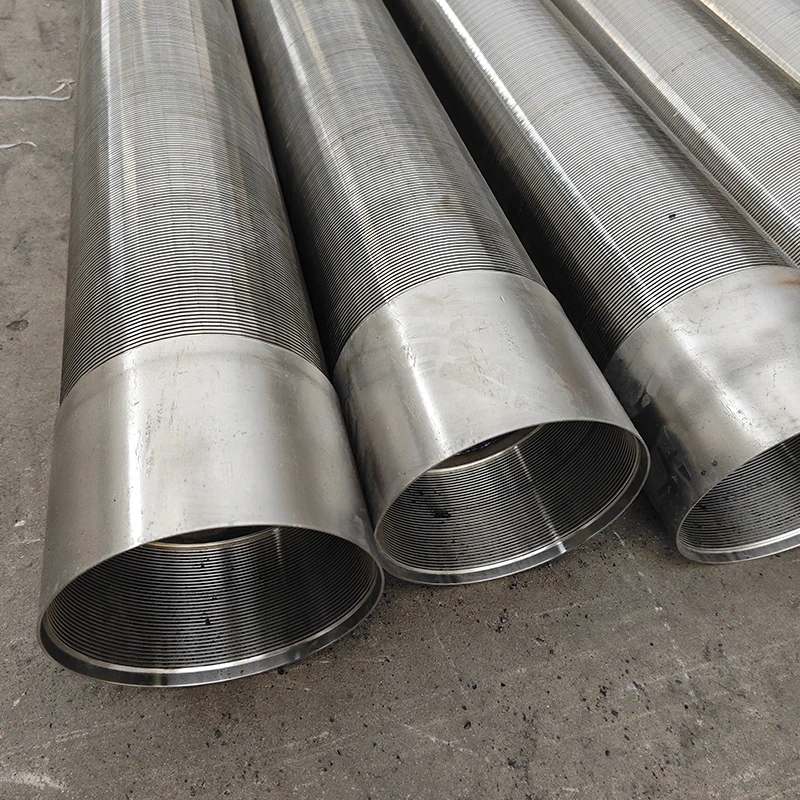

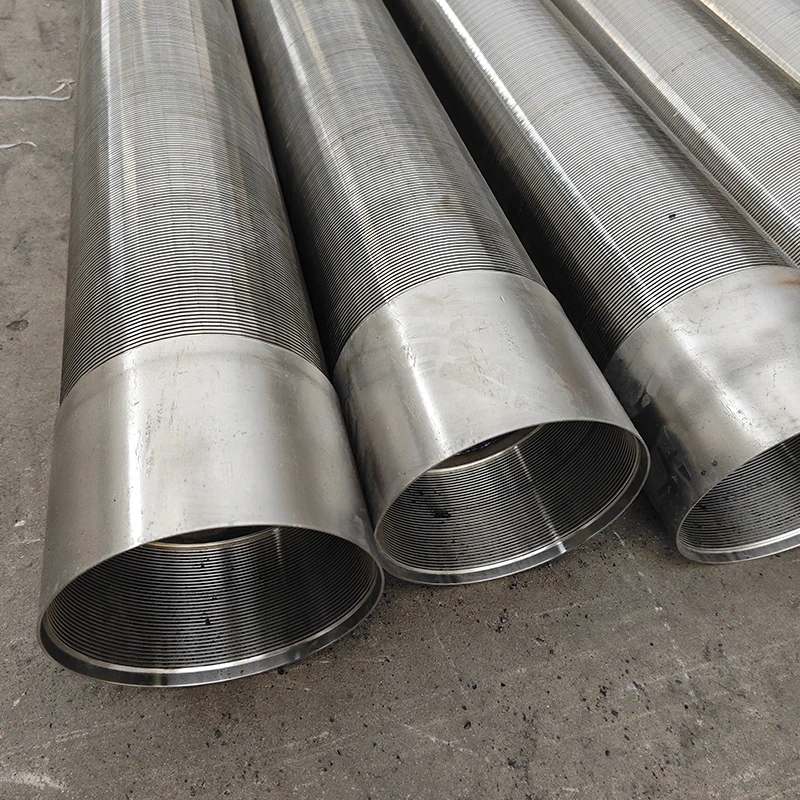

Well Screens

The wedge wire well sand control screen is a specialized screening solution designed to manage sand and fines in oil, gas and water wells, ensuring optimal production while protecting the well infrastructure.

-

Wedge Wire Screen

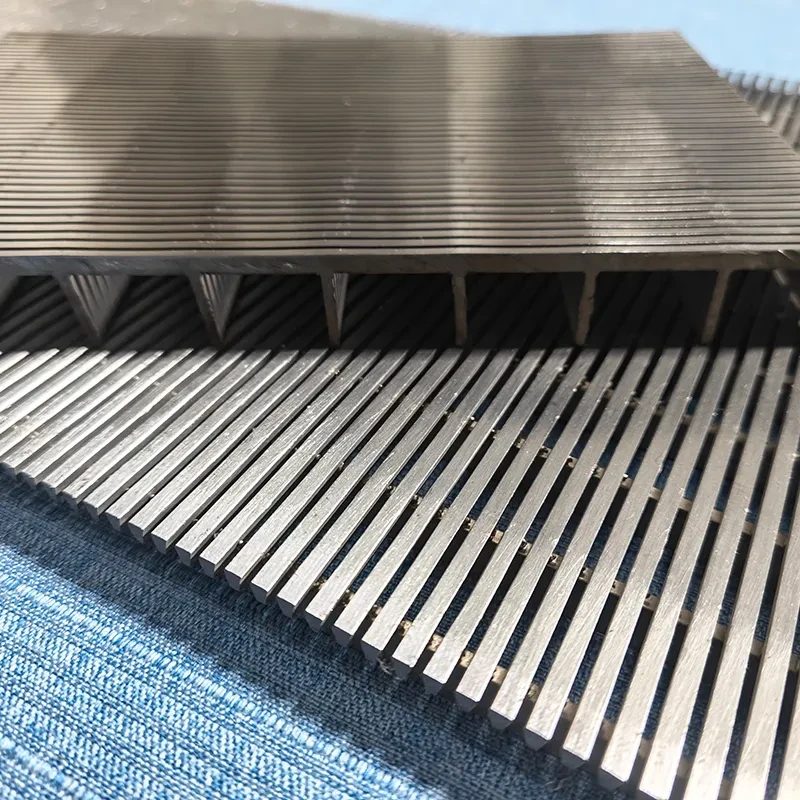

The wedge wire screen, also known as a V-wire screen or wedge wire mesh, is formed by welding wire(cross section is wedge) through a special welding technology welded on the support wire. It is a specialized screening solution widely used in various industrial applications for its durability and efficiency.

-

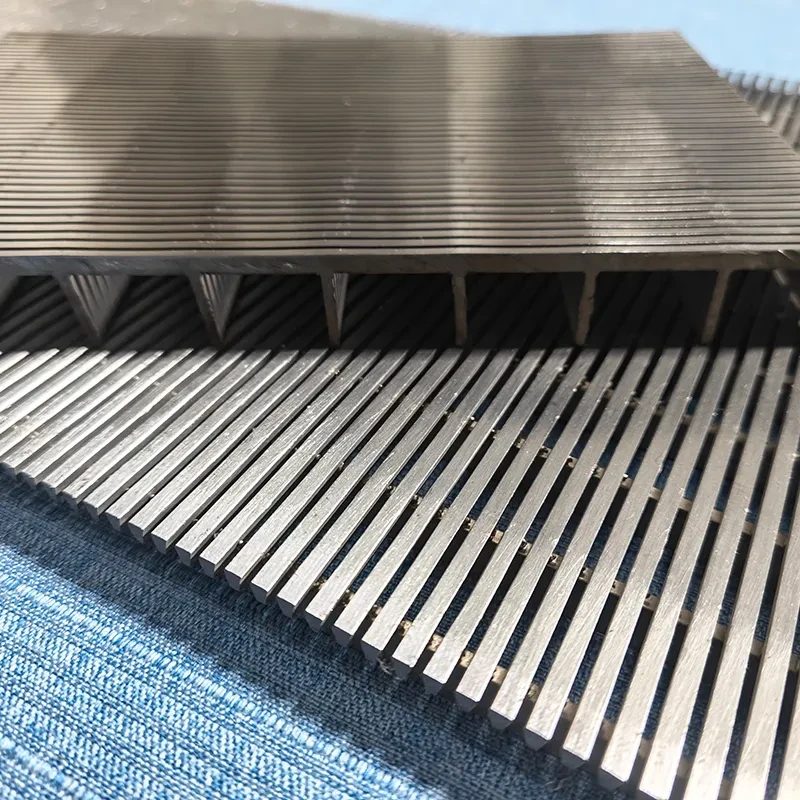

Coanda Screen

Coanda screen is also called Coanda hydro screen, Coanda intake screen, provides self-cleaning with the special geometry based on the Coanda effect. Coanda screens use tilted wedge wire to provide filtration to hydro, municipal water, and other facilities.

-

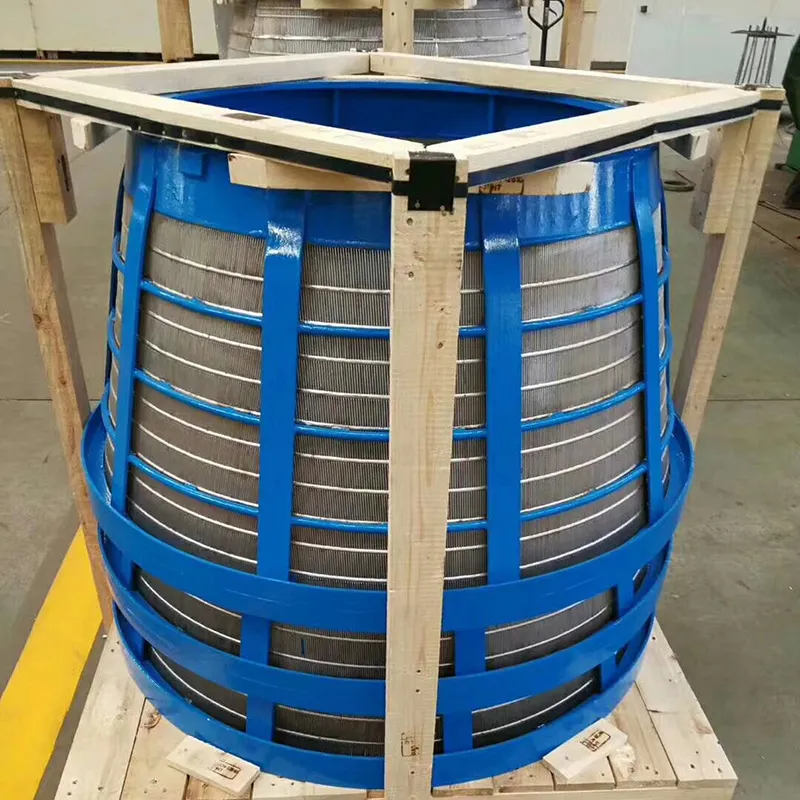

Rotary Drum Screens

Rotary drum screens, also known as wedge wire rotary screen, wedge wire screen cylinder, is designed for liquid filtration applications. Our rotary drum screen filter is a round rotating drum made of wedge wire mesh screens

-

Wedge Wire Screen Welding Machinery

The wedge wire screen produced by the equipment is widely used in the oil, gas and water well sand control industry, especially used in the water and oil well industry. It is also widely used in sewage treatment and water purification.

Customized specification is available by different mold.(SY/T5182-2008)

-

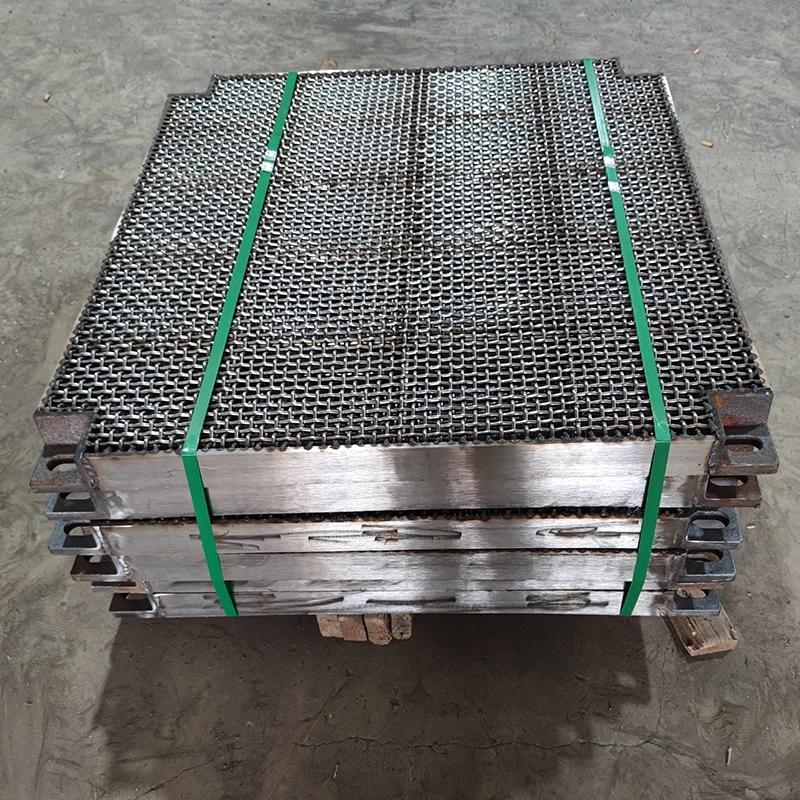

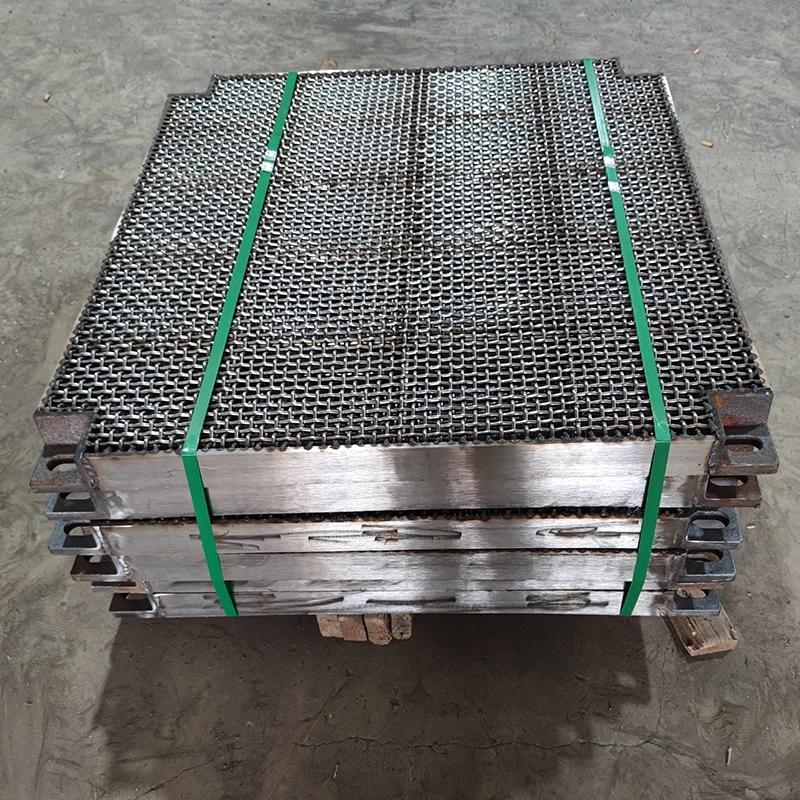

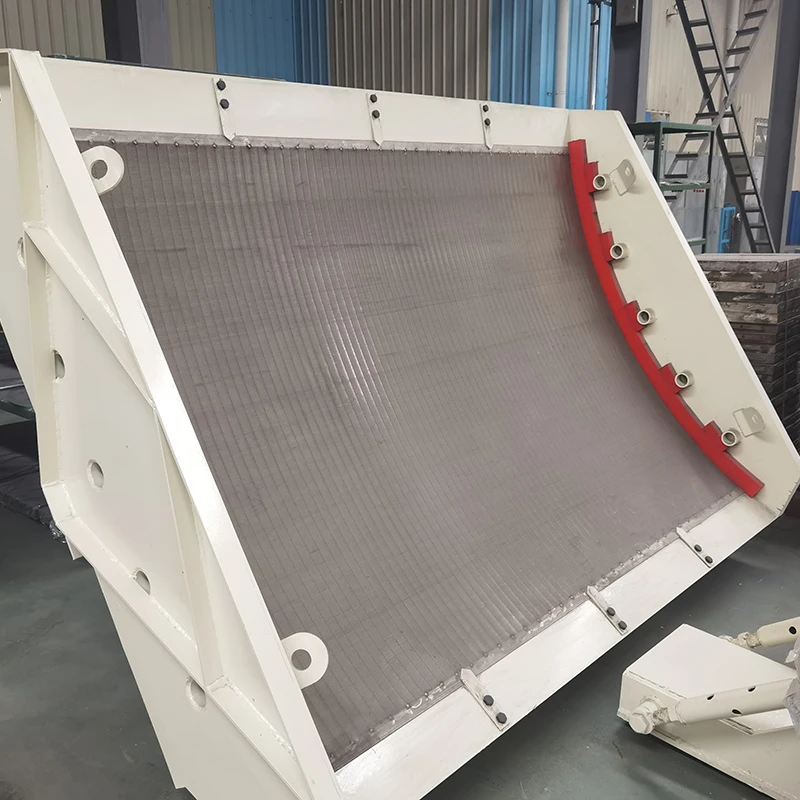

Flat Wedge Wire Screen

The flat wedge wire screen is a crucial component in mining processing. The screens adopt the stainless steel wedge wire screens to form a robust screen surface; The edge may adopt resilient and wear-resistant polyurethane material or the stainless steel material frame.

-

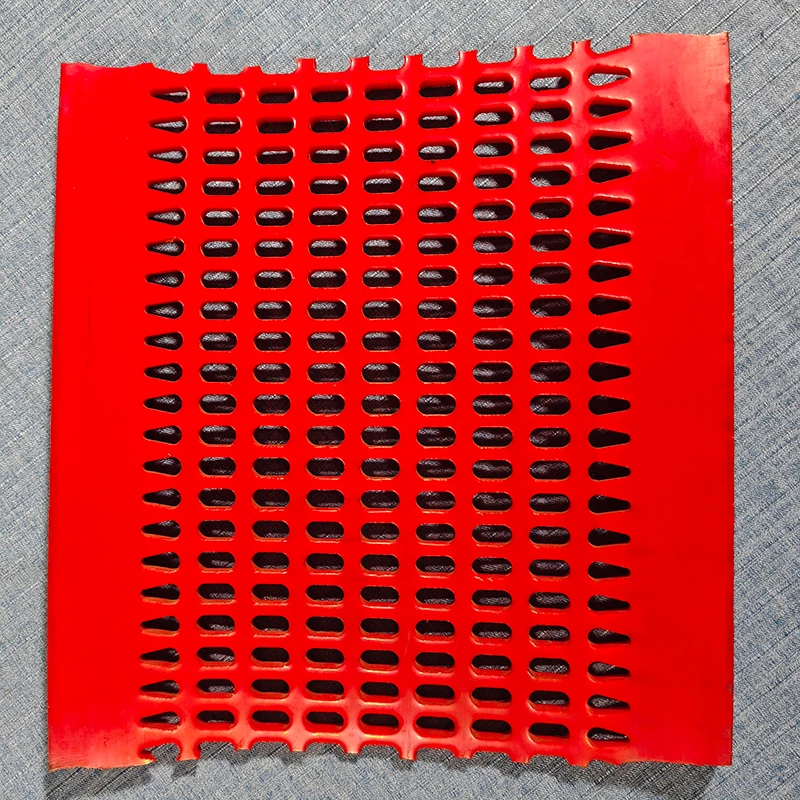

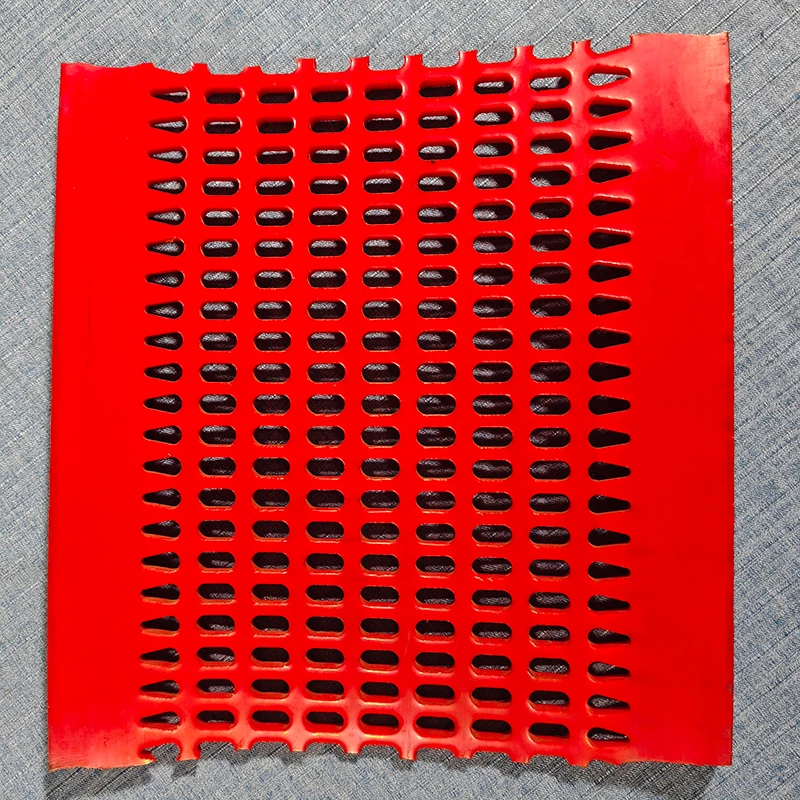

Perforated Plate

The perforated plate with polyurethane frame is made of polyurethane material frame and inside steel perforated plate screen. This enhances the screen's overall strength while adding flexibility to absorb shocks and reduce noise during operation.

The uniform perforations facilitate efficient separation while minimizing the risk of clogging or blinding, ensuring smooth operation during the screening process.

-

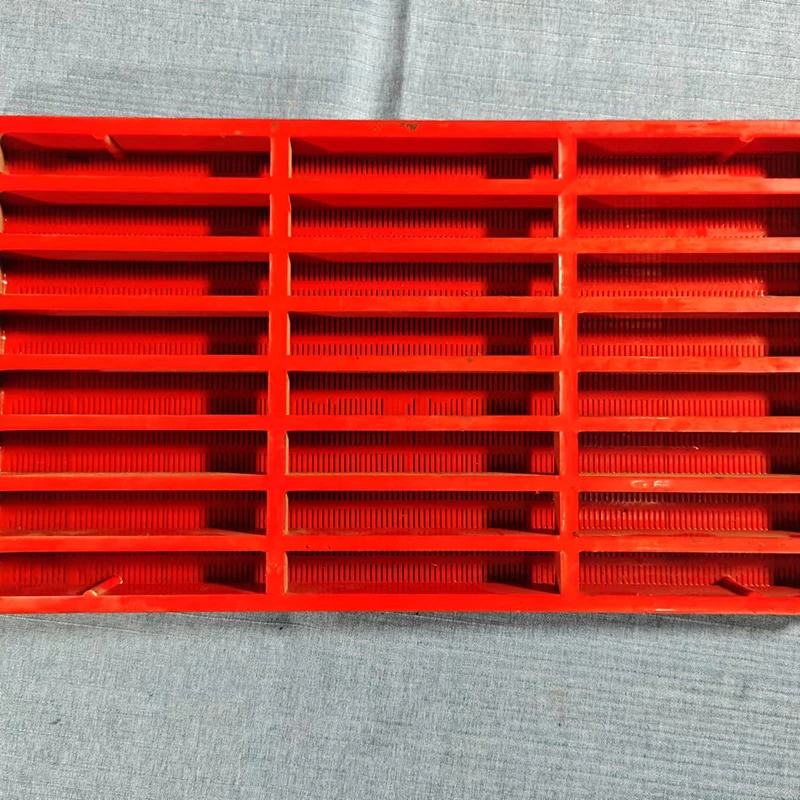

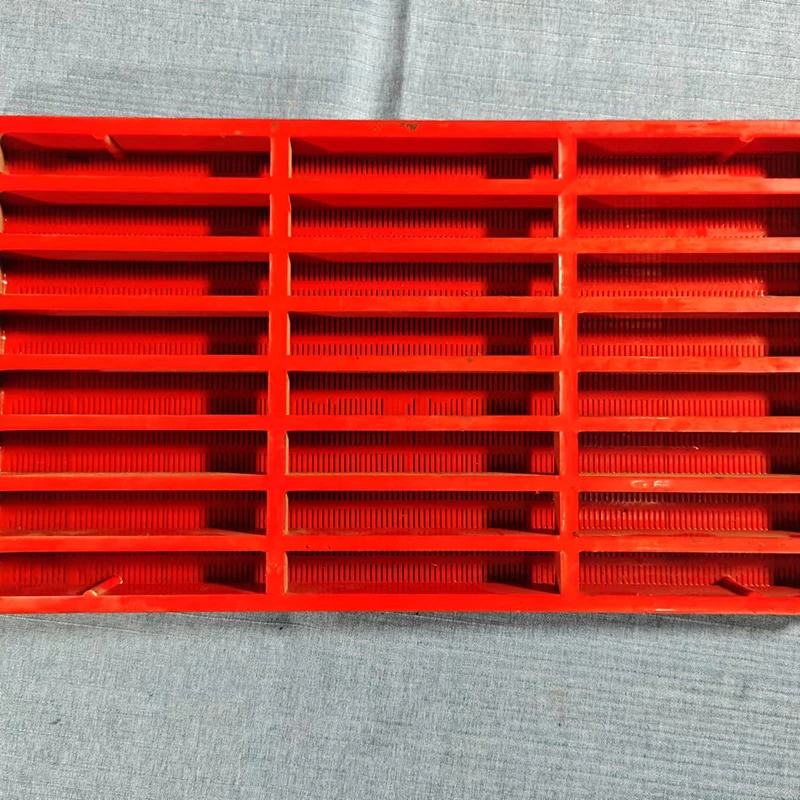

Flexible Rod Screen Plate

The flexible rod screen plate is mainly composed of multiple elastic rods, which are usually made of high-strength, wear-resistant materials spring steel. The elastic rods are fixed together by a specific connection method to form an integral screen surface. The flexible rod screen plate is a key component widely used in the field of vibrating screening machinery, especially in the screening process of handling wet granular materials.

-

Jigging Screen Plate

Jigging screen plates, also known as jig screens, are specialized screening surfaces used in jigging machines for the separation of materials based on size and density.

-

Self Cleaning Screen

Self-cleaning screen, also known as anti clogging screen, is a specific type of screening media made with multiple individual metal wires or polyurethane material.

-

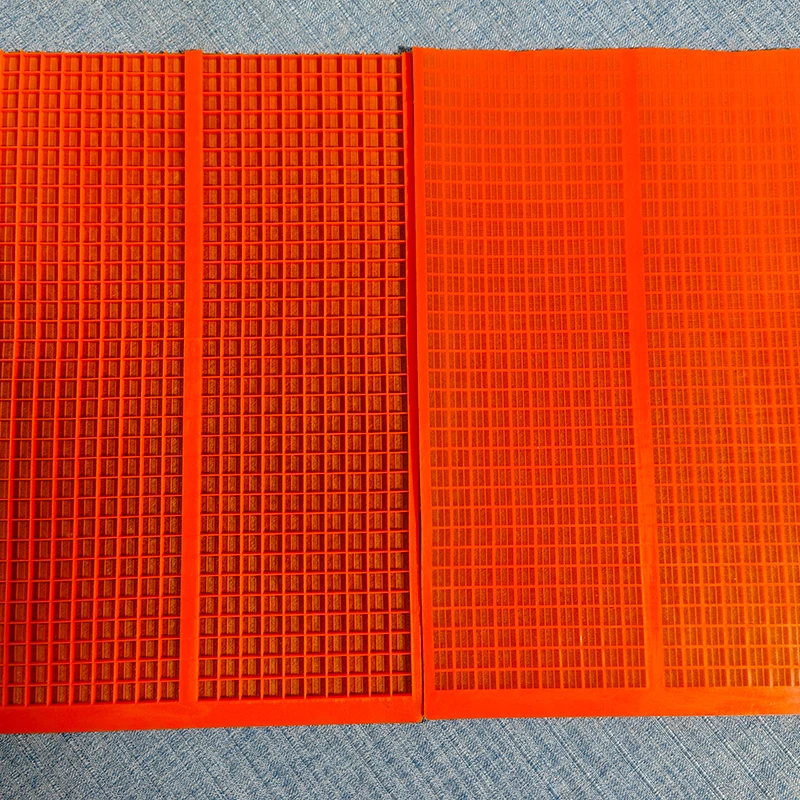

Polyurethane Slot Screen Plate

A Polyurethane sieve plate is a type of screening panel designed for industrial applications that require durability, flexibility, and effective particle separation. Material with high-quality polyurethane (PU), chosen for its excellent wear resistance, flexibility, and chemical resistance.

-

Polyurethane Blind Plate

The polyurethane blind plate is a type of screen plate with many excellent properties, which is widely used in vibration screening equipment.

-

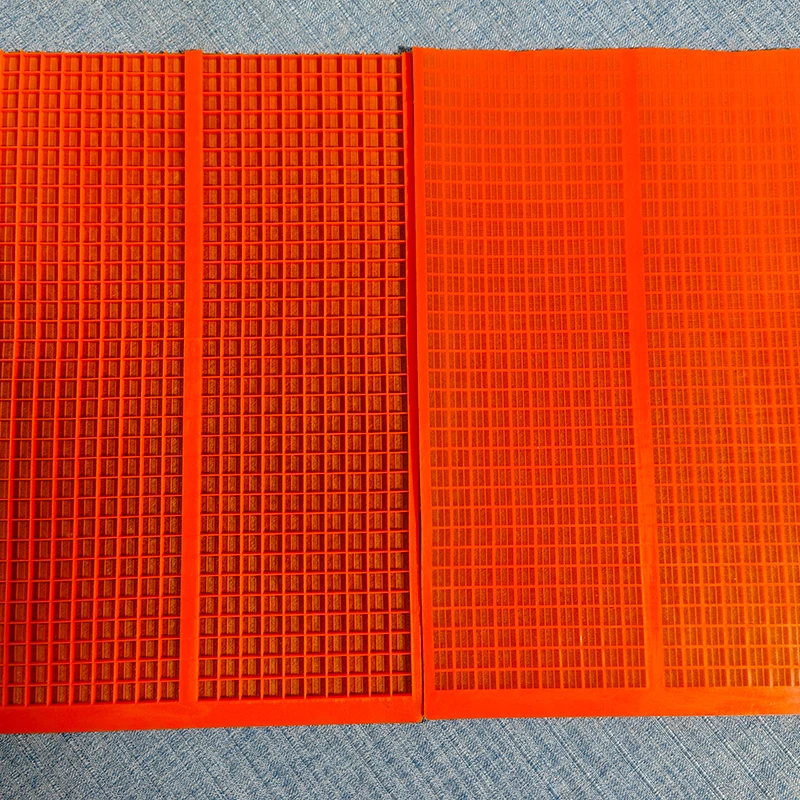

Flip Flow Screens

Flip flow screens, also known as flip flop or elastic mesh screens, are generally square or rectangular mesh products made of polyurethane raw materials. It is suitable for fine, sticky, wet (such as fine particle screening in high moisture raw coal and coal) and other equipment for screening more difficult to screen materials, especially when the processing material is prone to clogging the screen.

-

Polyurethane High Frequency Screen

Polyurethane high frequency screen is a kind of network product made from polyurethane, which has the advantages of high wear resistance, high rebound, elastic connection and hydrolysis resistance.

-

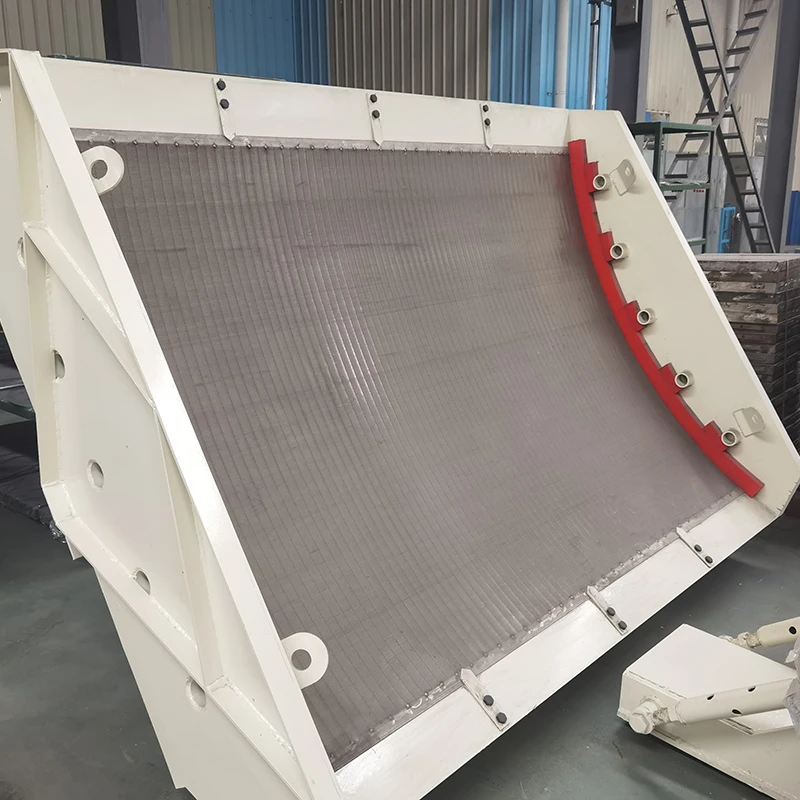

Wedge Wire Sieve Bend Screen

The wedge wire sieve bend screen, also known as DSM screens, is a robust and efficient screening solution commonly used in various industrial applications. Made primarily from stainless steel or other durable materials, these screens feature a unique curved shape, so it’s called bend screen.