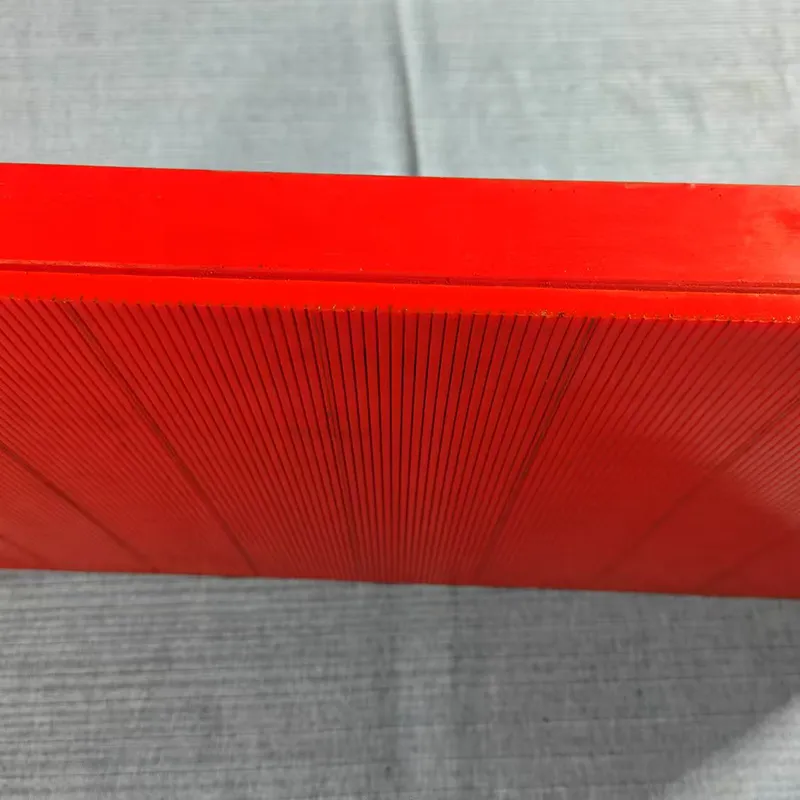

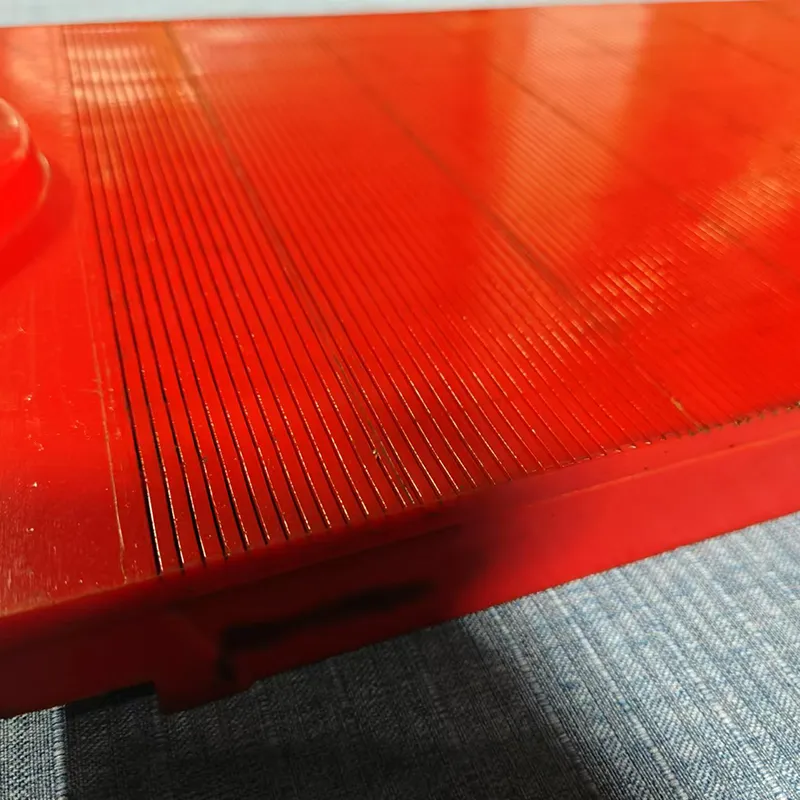

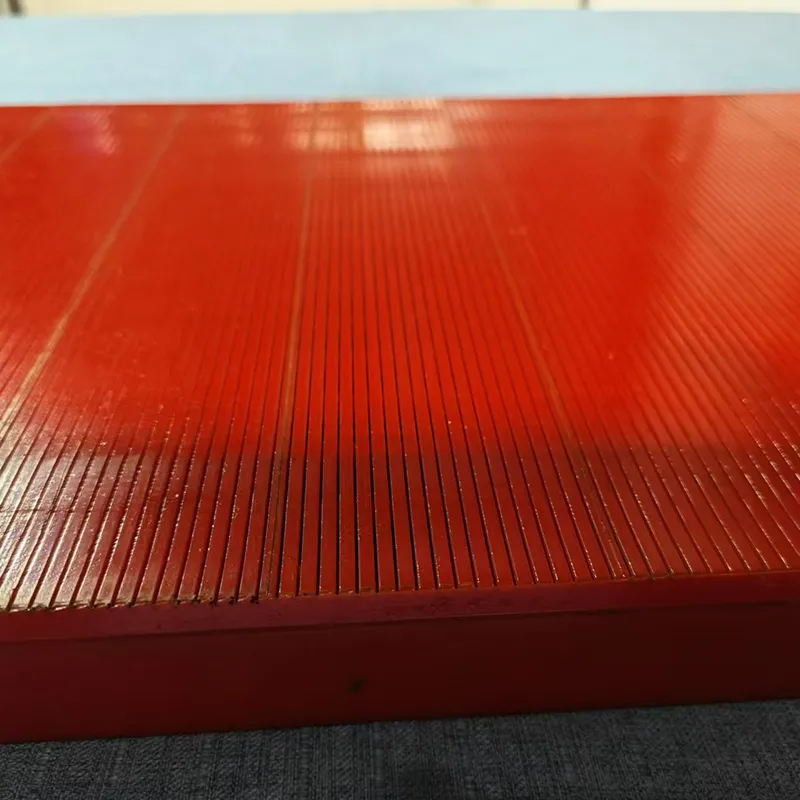

Good wear resistance: The polyurethane sieve plate has much higher wear resistance than steel screen plate and ordinary rubber screen plate. This high wear resistance greatly extends its service life and reduces the frequency of maintenance and replacement.

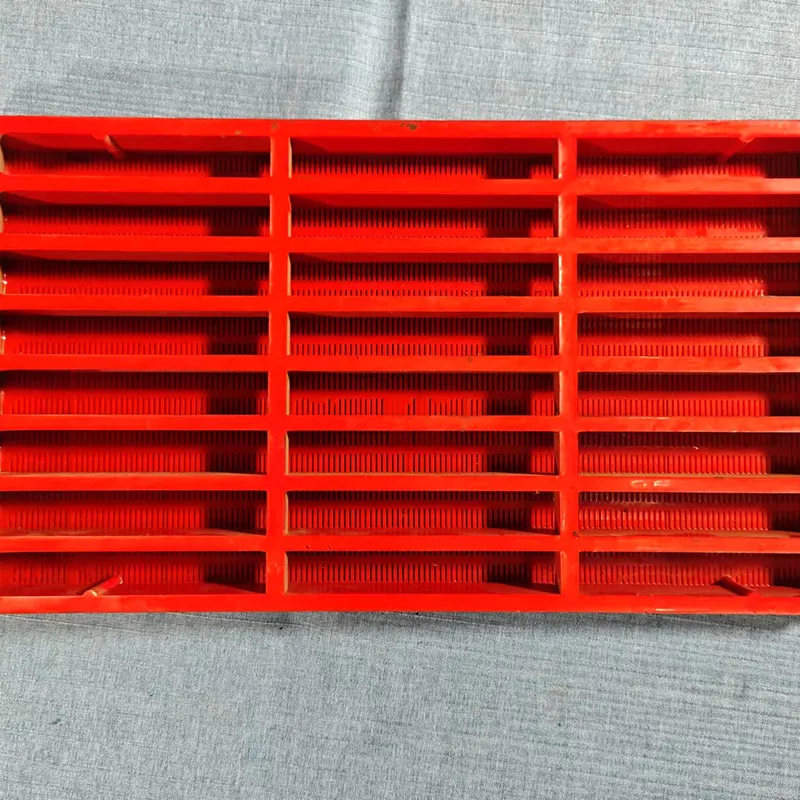

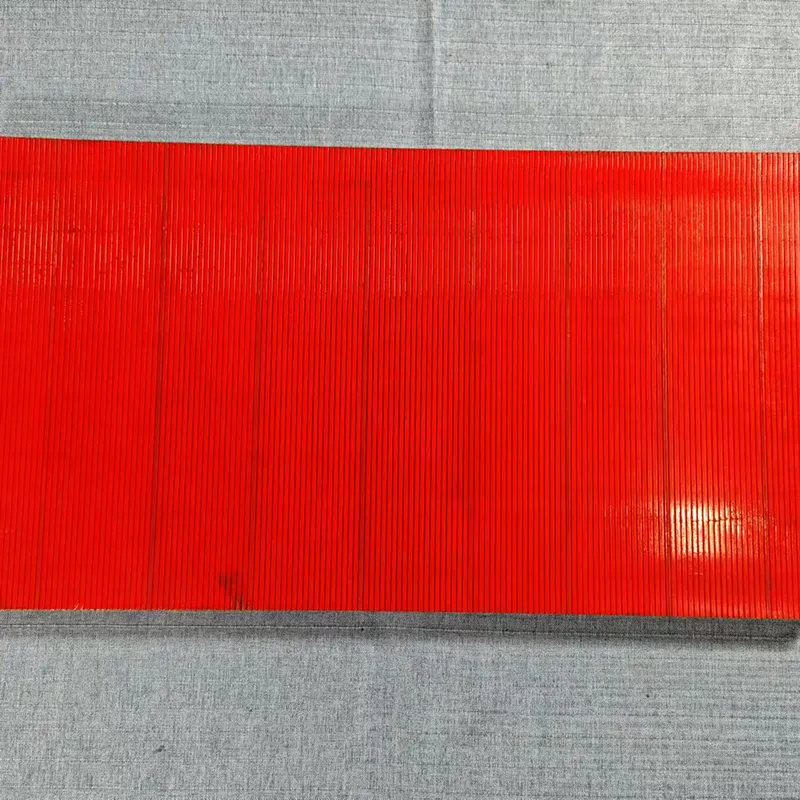

Strong self-cleaning ability: Due to its unique slit structure design, the polyurethane sieve plate can effectively avoid screen clogging in the screening process and maintain the stability of screening efficiency.

Good moisture resistance: the polyurethane sieve plate can work under the condition of water as the medium, and in the case of water, oil and other media, the friction coefficient is reduced, which is more conducive to screening and improve screening efficiency.

Easy installation and disassembly: the polyurethane sieve plate adopts new product structure, convenient installation and disassembly.

Coal washing plant: used for classifying and dewatering coal.

Coking plant: Used for the screening and classification of coke.

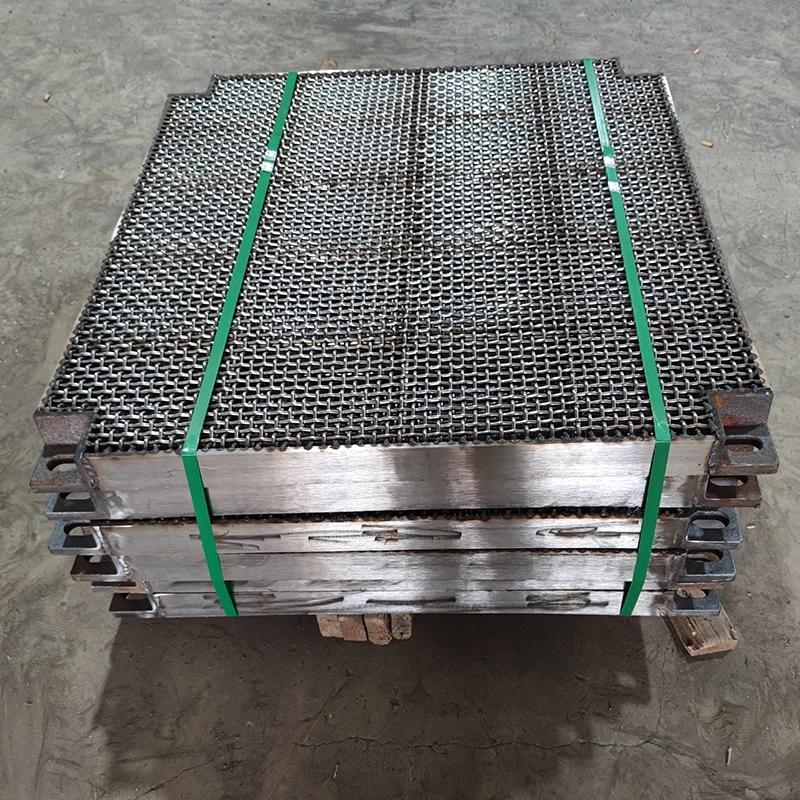

Mining: Used for crushing and screening of ore.

Power plants: For the screening and purification of coal and other fuels.

Dredging company: used for the separation and removal of sediment.

Metallurgy, petroleum, petrochemical and other industries: used for screening and filtering of various materials.

|

Hole type |

Size of sieve pore |

Thickness |

Hole type |

Size of sieve pore |

Thickness |

|

Bar steam |

0.15*15 |

15-60 |

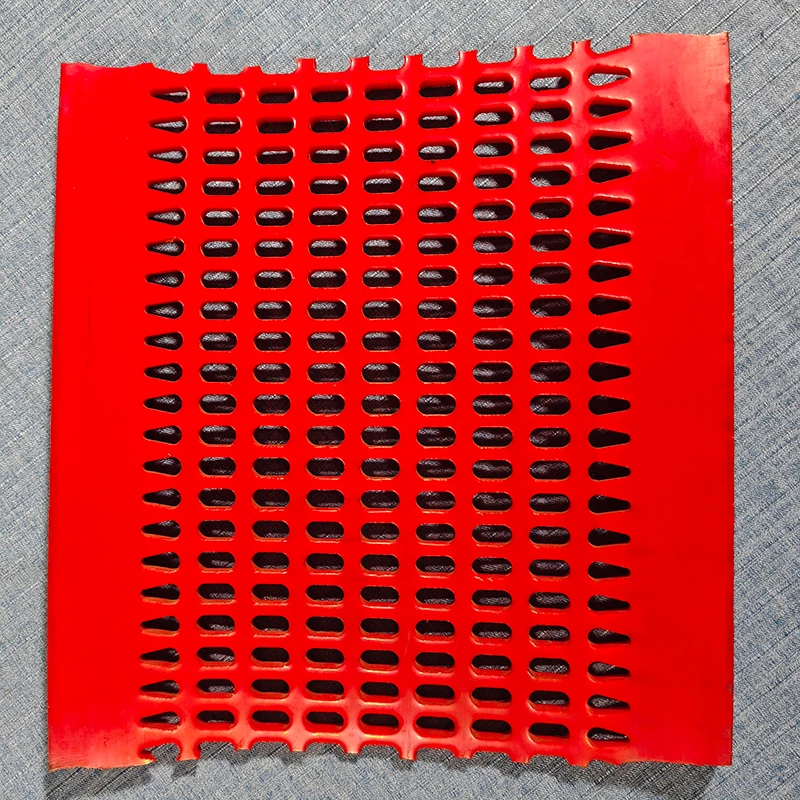

Round hole |

75 |

40-60 |

|

0.2*15 |

15-60 |

100 |

45-60 |

||

|

0.3*15 |

15-60 |

140 |

55-60 |

||

|

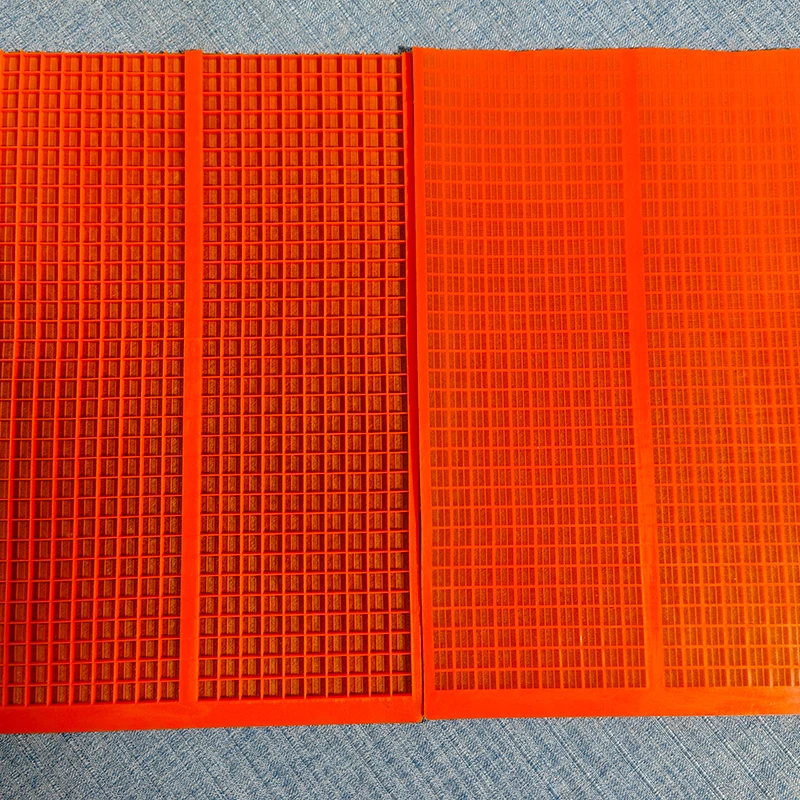

Square hole |

4.7*4.7 |

20-55 |

Rectangular |

20*25 |

25-30 |

|

5.5*5.5 |

20-55 |

40*45 |

30-35 |

||

|

10*10 |

20-55 |

25*50 |

25-50 |