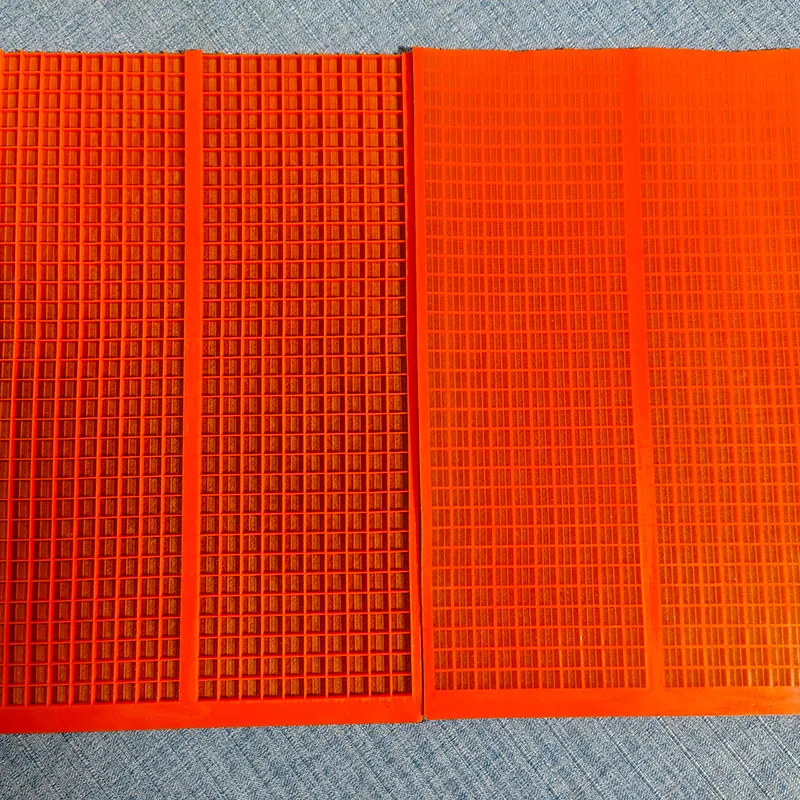

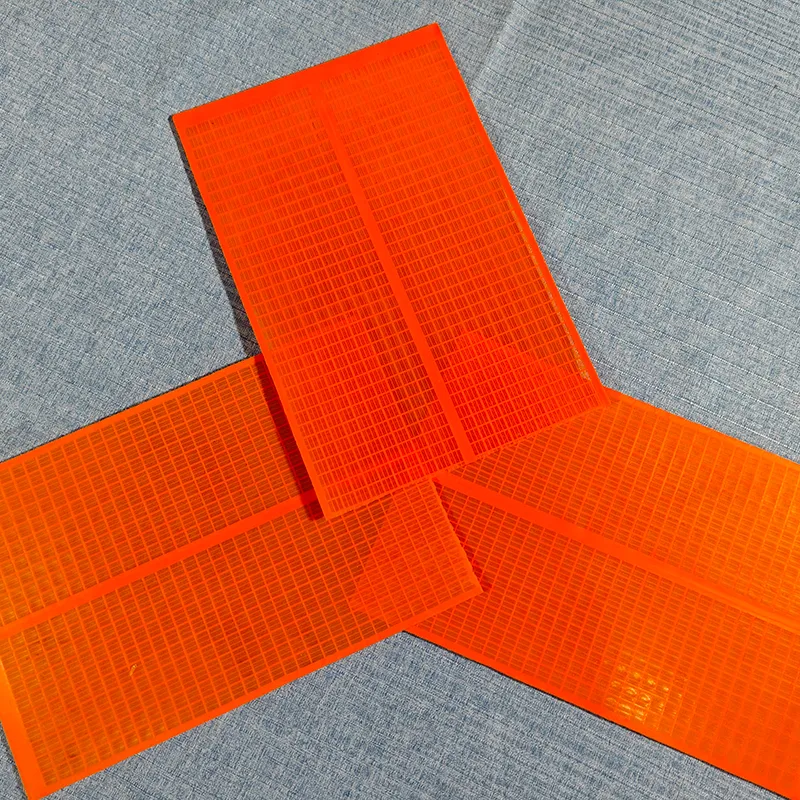

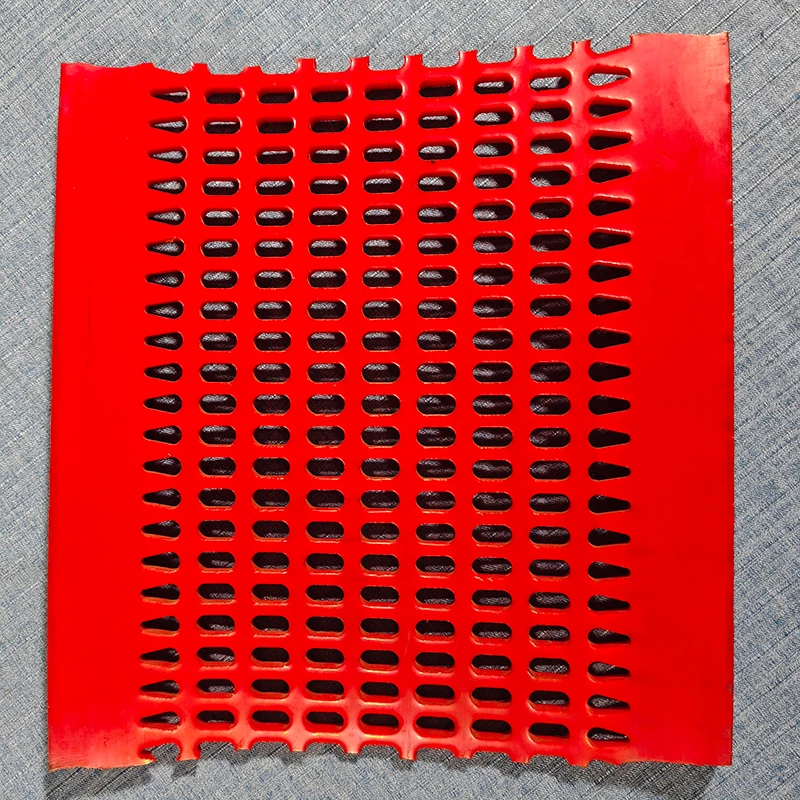

Classification according to the arrangement of sieve wire: including diagonal hole efficient self-cleaning screen plate (screen plate strength, long service life, high screening accuracy) and parallel wave hole efficient self-cleaning screen plate (screen plate opening rate is high, good screening effect).

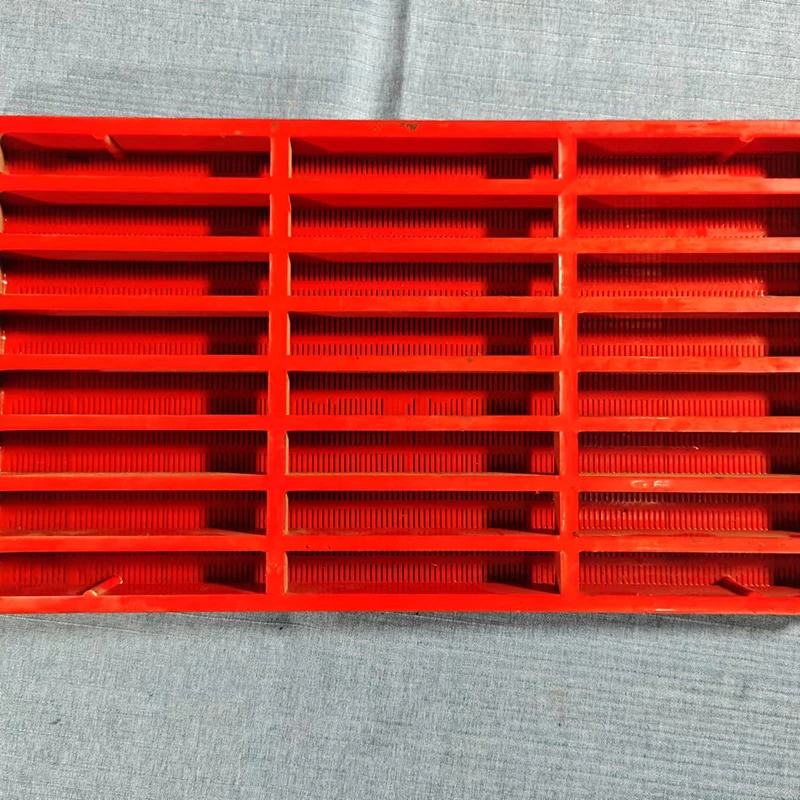

Classification by use: there are coal grading screen plate (grading size 3~50mm), desliming screen plate (grading size 0.35~3mm, using alloy steel material with high wear resistance and strength), desliming screen plate (grading size 0.35~1mm, non-magnetic stainless steel material) and so on.

|

Screen size: |

1045mm*700mm,1220mm*700mm,etc. |

|

Aperture ratio: |

35%-43% |

|

Normal Service Life: |

6-12 months |

|

Hardness: |

80-95 Shore A |

|

Minimum aperture: |

0.015mm |

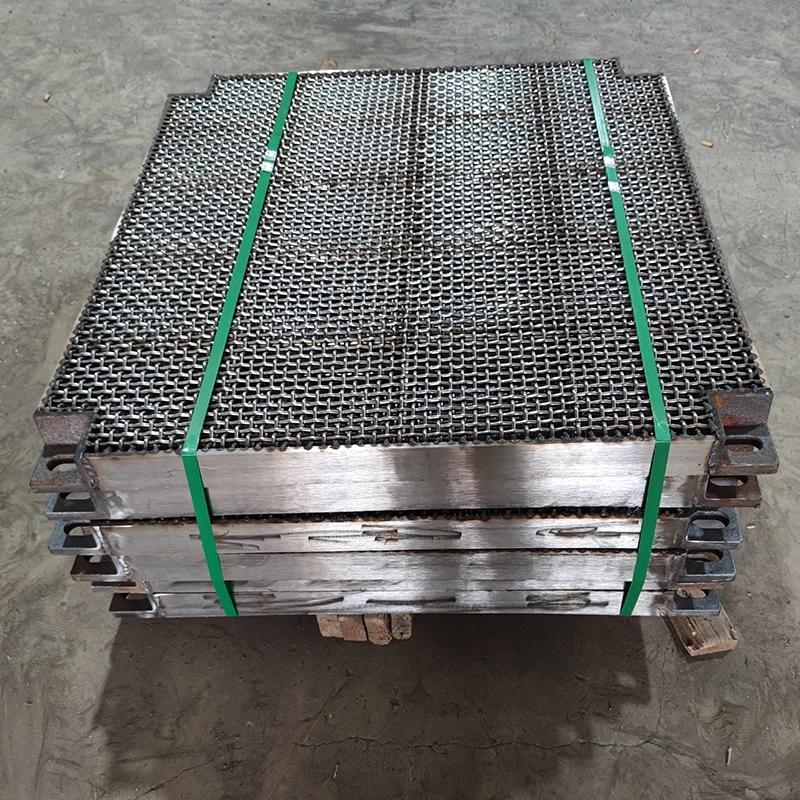

Polyurethane high frequency screen is widely used in coal washing, mining and other related industries, for the separation of granular materials, dehydration, desliming, desliming and product classification, especially in crushing, beneficiation and screening and other working environments are extremely harsh occasions.