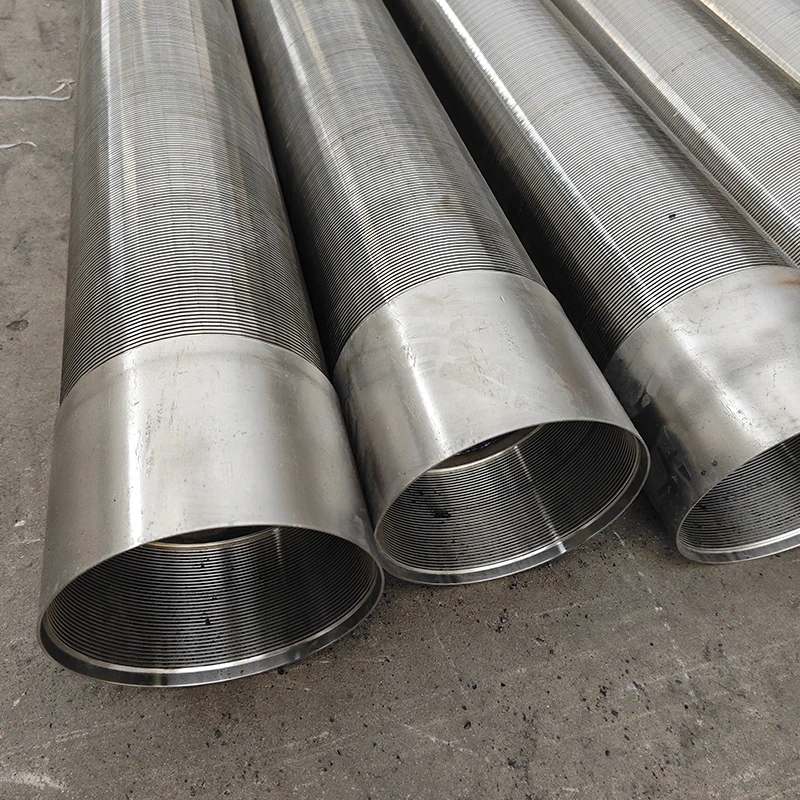

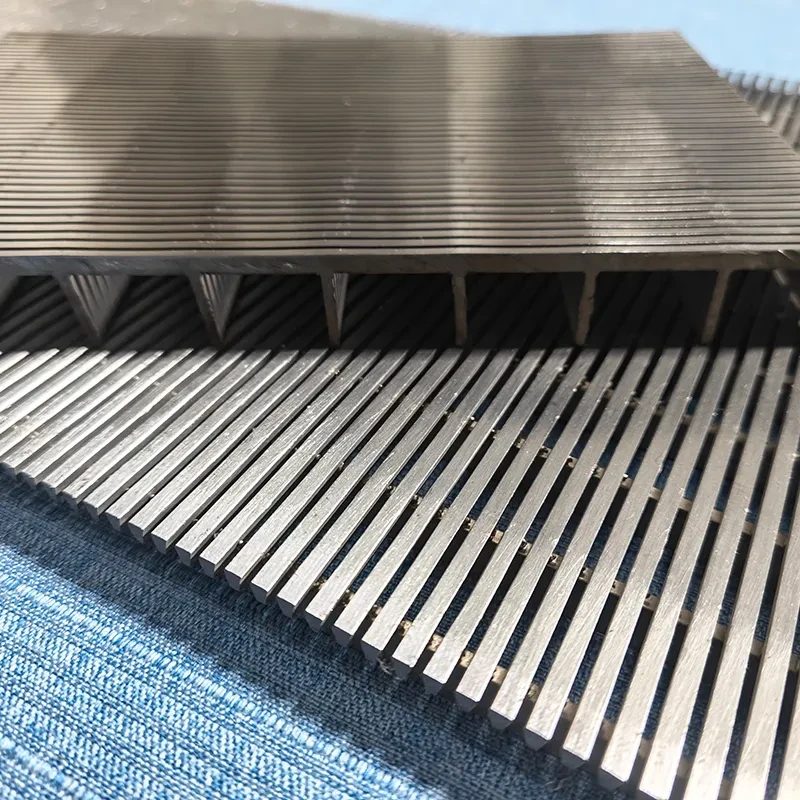

Winding with high precision, slot tolerance within 0.10mm.

High efficiency, maximum winding 6 meters per hour.

Transmission part adopt imported ball screw.

Sending wire part can be adjustable in vertical, horizontal and circumferential direction, meanwhile straightening the wire.

Welding parameters can be adjusted by the welding machine controller.

Circulating water cooling system.

Electrode wheel goes together with lathe, easily to maintain without disassemble.

One set of mold for normal product, special mold need to be customized.

|

Max machining diameter |

mm |

200,300,500 |

|

Max machining length |

mm |

6,000 |

|

Winding Pitch range |

mm |

0.01-50 |

|

Winding Accuracy |

mm |

0.10 |

|

Max rotational speed of wire wheel |

rpm |

1-30 |

|

Max processing efficiency |

m/hour |

6 |

|

Fast moving speed of pulling shaft |

mm/min |

1,000 |

|

Max turning speed of the spindle |

rpm |

80 |

|

Max travel of net shaft |

mm |

6,500 |

|

Drawing shaft positioning accuracy |

mm |

0.05/1,000 |

|

Cooling Type |

|

Water cooled |

|

CNC Control System |

|

MUTO |

|

Power of main motor |

kW |

120kw |

|

Overall dimension(LXWXH) |

mm |

13,500 X 3,500X 2,200 |