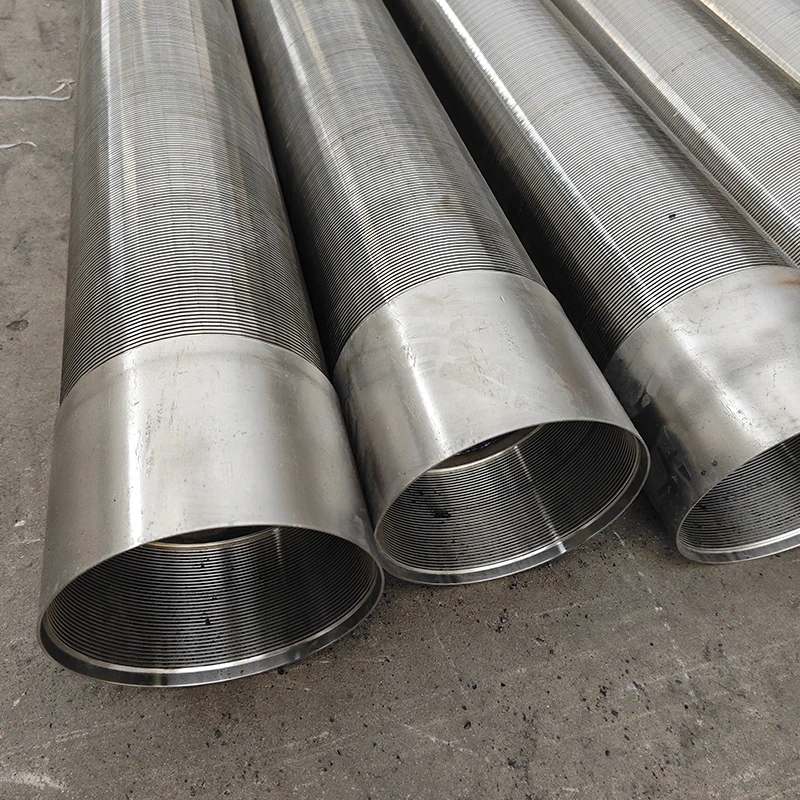

Our rotary drum screens are constructed with all-stainless steel, ensuring durability and longevity. The end of the drum screen is designed with a welded flange or welding ring, facilitating easy installation on drum screening machines.

The main application is as a rotary screens, collectors such as screen laterals and nozzles, resin traps, in-line strainers, water intake screens, well screens, and many other applications involving liquid-solid separation.

* Rotary drum screens for the sugar industry

* Dewatering treatment of manure in large-scale livestock farms

* Poultry & meat processing effluent

* Seafood processing effluent

* Vegetable & fruit processing effluent

* Pulp & paper debarking water

|

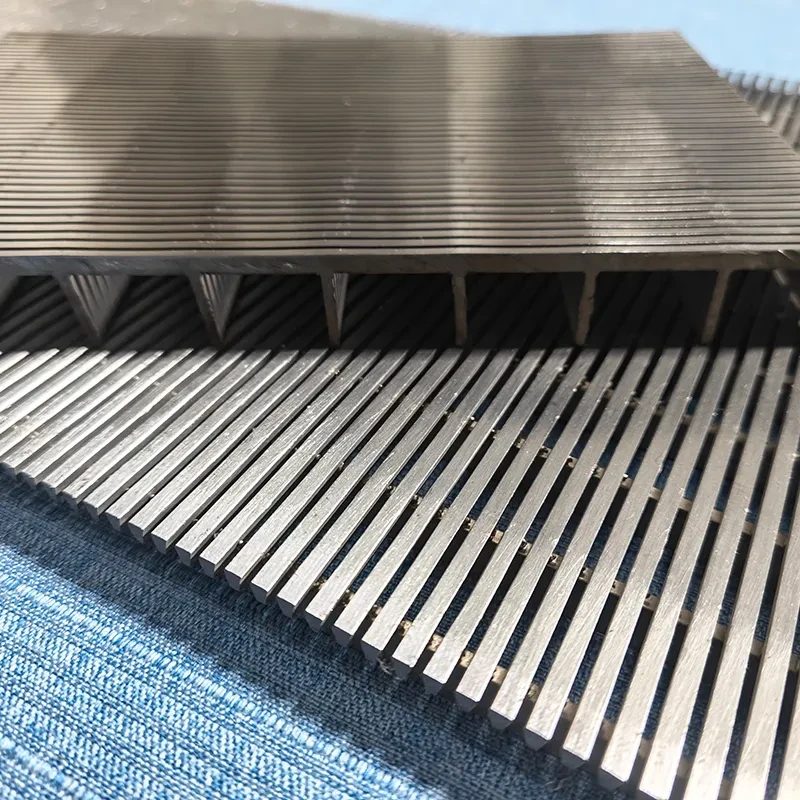

Material |

Stainless steel 304/316L/321/310S, Duplex steel 2205/2507 Hastelloy, 904L, etc. |

|

Support profile |

Triang0.02 mm-10mm, or customized sizesular (V-shaped, wedge), square, round rod, flat bar, water drop |

|

Slot size |

5μm-5 mm |

|

Cylinder diameter |

100 mm-2,500 mm or customized sizes |

|

Length |

Up to 6000mm |