- Fundamentals of wedge wire screen technology

- Technical superiority in filtration and durability

- Comparative analysis of leading manufacturers

- Performance data across industrial applications

- Custom design solutions and engineering process

- Industry-specific application case studies

- Optimal sourcing strategies for buyers

(wedge wire screen for sale)

Why Wedge Wire Screens Dominate Modern Filtration Systems

Industrial screening technology has evolved significantly with wedge wire screens becoming essential in separation processes. Unlike woven alternatives, these screens feature V-shaped wires welded onto support rods, creating precise slot openings from 0.02mm to 25mm. This construction delivers 38-42% greater open screening area compared to perforated plates while maintaining structural rigidity. Mining operations, water treatment plants, and aggregate industries increasingly choose wedge wire solutions due to their non-clogging properties and ability to withstand pressures up to 250 PSI without deformation.

Manufacturers craft wedge wire screens using 304, 316, or duplex stainless steel for corrosion resistance in harsh environments. The continuous slot design particularly excels in sizing coal and mineral ore, where operational data shows 30% increased throughput versus conventional screens. According to industry studies, properly maintained wedge wire screens demonstrate service lifespans exceeding 15 years in continuous mineral processing applications, reducing replacement frequency by 60% compared to polyurethane alternatives.

Technical Advantages Defining Modern Screening Solutions

Flow dynamics engineering makes wedge wire screens fundamentally superior in liquid-solid separation. The gradual widening of slots from the feed to discharge end prevents material buildup while maintaining laminar flow conditions. This design achieves 92-98% separation efficiency in phosphate dewatering applications, as documented in Florida mining operations. Thermal bonding during manufacturing creates monolithic structures without weak points, enabling vibration resistance at frequencies up to 1,200 RPM with minimal fatigue.

Engineering innovations now incorporate variable wedge geometries tailored to material characteristics. Abrasive applications utilize reverse-welded profiles where the wear-resistant wire surface faces incoming material, extending operational life by 45% in sand and gravel screening. For sticky materials like clay and biomass, specialized self-cleaning configurations with oscillation assistance maintain 95% of original throughput capacity after 500 operating hours – a key advantage considering traditional screens experience 40% performance degradation under similar conditions.

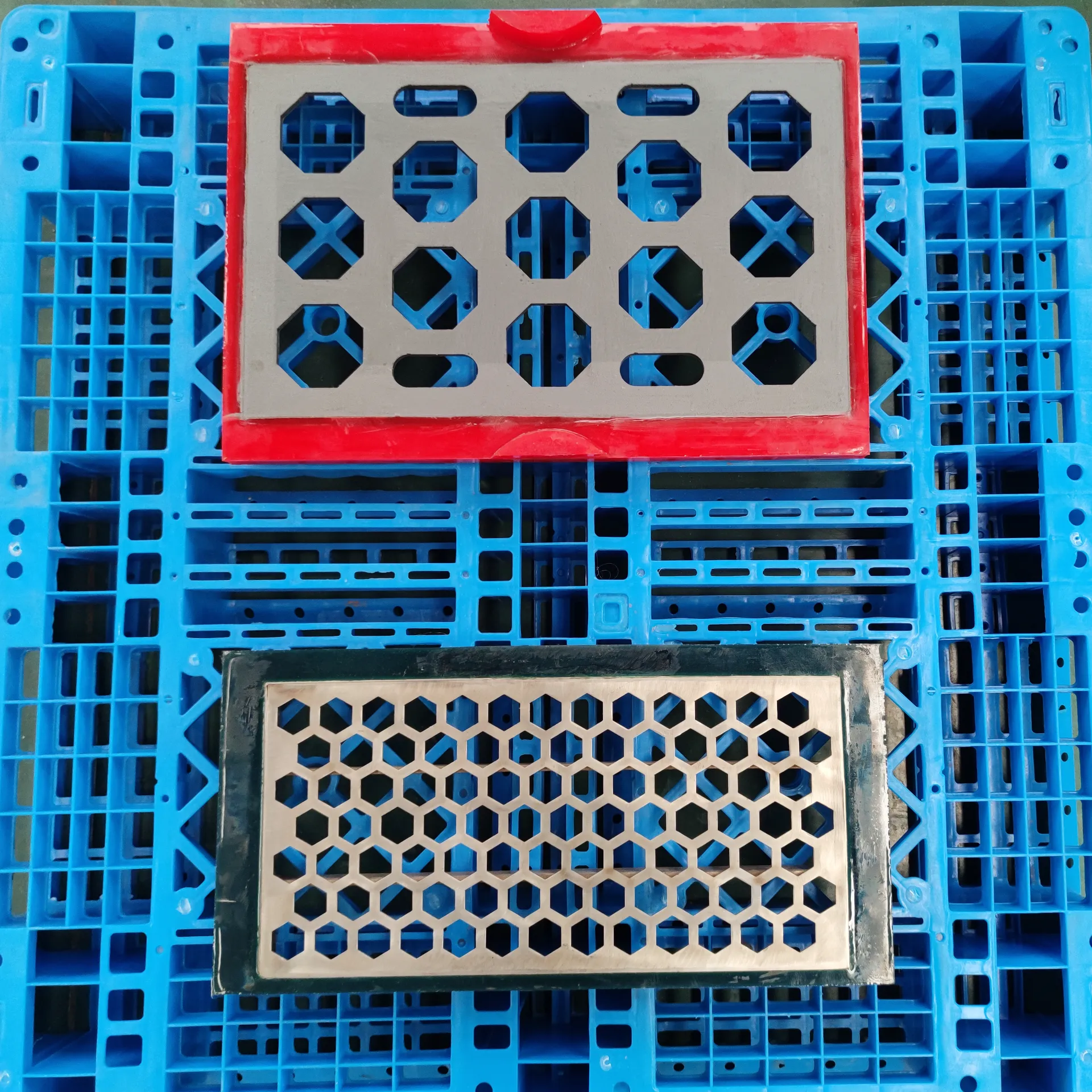

Manufacturer Comparison: Engineering Excellence Analysis

The industrial screening market features distinct technical differences between leading producers. Material specifications and welding techniques significantly influence performance metrics, especially under high-temperature operations or corrosive environments. Our comparative assessment examines critical parameters for three leading wedge wire screen suppliers:

| Manufacturer | Material Options | Slot Precision Tolerance | Max Operating Temp | Pressure Rating | Specialized Applications |

|---|---|---|---|---|---|

| Industrial Screening Solutions | 304SS, 316SS, 2205 Duplex | ±0.01mm | 480°C | 300 PSI | High-temperature ash processing |

| Precision Wedge Wire Inc. | 316L SS, Alloy 904L | ±0.007mm | 340°C | 250 PSI | Desalination pre-filtration |

| Global Filtration Technologies | 316SS, Titanium | ±0.015mm | 550°C | 350 PSI | Geothermal brine separation |

Regional variations in manufacturing standards critically affect corrosion resistance and fatigue strength. European producers typically exceed ASTM A480 standards with stricter inclusion control, improving chloride resistance by 20-30% in desalination applications. North American manufacturers counter with shorter lead times (average 18 days versus 32 days) without compromising weld integrity through automated TIG processes.

Application Performance Metrics Across Industries

Industrial case studies demonstrate how design specifications translate into operational advantages. In phosphate beneficiation, wedge wire well screens with 0.5mm slots maintained consistent 94% recovery rates during 18-month evaluations despite abrasive conditions. Comparatively, perforated plate alternatives required monthly cleaning cycles and showed decreasing recovery after 6 months. Municipal water intake systems using custom-profile screens report a noteworthy 92% reduction in mechanical failures versus previous woven wire installations.

Flip-flow configurations show exceptional results for difficult-to-screen materials like shredded automobile fluff. By combining wedge wire panels with controlled elliptical vibration, operators achieved 98% material separation efficiency while reducing energy consumption by 15% compared to polyurethane alternatives. Aggregate producers switching to wedge wire screens documented 23% increased throughput with simultaneous reduction in undersize contamination below 3%. Capital costs are typically amortized within 14 months of operation through these efficiency gains and reduced maintenance expenses.

Custom Engineering: Matching Design to Operational Demands

Precision engineering transforms standard screens into application-specific solutions. Sophisticated modeling software now determines optimal parameters including slot geometry, support rod configuration, and modular connection systems. This digital prototyping process predicts structural performance under dynamic loading conditions before manufacturing begins. Case in point: a Canadian oil sands operation required wedge wire panels to withstand 1,500 tons/hour flow rates at -40°C. Computational analysis determined that 14mm-thick profile wires with enhanced weld penetration were necessary.

Customization extends beyond materials to encompass profile geometry – convex screens for tank bottoms, cylindrical baskets for centrifugation, and curved panels matching classifier contours. The most advanced flip flow screen designs incorporate variable slot sizes along the screening path to accomplish multi-stage separation in a single unit. For specialized requirements like food-grade polishing, manufacturers offer electropolished finishes achieving surface roughness (Ra) below 0.8µm to prevent bacterial adhesion. These engineered solutions typically increase efficiency by 25-40% over standardized products in demanding applications.

Field Validation: Documented Success in Extreme Conditions

Real-world installations validate engineering principles in challenging environments. Offshore oil platforms have deployed 316L stainless steel wedge wire screens for seawater intake since 2018, with zero replacements reported despite constant exposure to marine organisms and corrosive elements. These units feature specialized backwash nozzles maintaining 98% open area after three years continuous operation. Similarly, Canadian oil sands operations run custom-designed screens 24/7 at -35°C with documented availability rates exceeding 99.4% – far surpassing the industry average of 92% for screening equipment.

Coal preparation plants provide compelling performance data when upgrading to engineered screening solutions. A West Virginia facility replaced traditional polyurethane panels with abrasion-resistant wedge wire screens featuring reverse-welded profiles. After 14 months, throughput increased by 28% while maintenance costs decreased by $18,000 monthly. Mineral separation plants employing our high-temperature wedge wire screens achieved 60-day continuous operation cycles – double the industry standard for iron ore pelletizing applications requiring screens to withstand temperatures exceeding 450°C.

Strategically Sourcing Premium Wedge Wire Screen for Sale

Procurement strategy determines operational success when sourcing industrial screening components. Technical specifications should prioritize material certification validation over unit cost savings – verified MTRs (Mill Test Reports) ensure metallurgical properties match application requirements. Beyond material considerations, evaluate manufacturing protocols including automated welding processes that provide better joint consistency than manual techniques. Third-party inspectors should validate profile dimensions within ±0.015mm tolerances across entire production batches.

Industry trends show increasing preference for suppliers offering comprehensive engineering services alongside manufacturing. Leading providers now conduct site evaluations using laser scanning to create precision-fitted components. Forward-thinking manufacturers have reduced delivery times for complex well screen assemblies from 12 weeks to under 21 days through advanced robotics in fabrication. When evaluating flip flow screen for sale options, request validated acceleration resistance data specific to your material characteristics since screen dynamics critically influence separation efficiency and longevity.

(wedge wire screen for sale)

FAQS on wedge wire screen for sale

Q: What types of wedge wire screens are available for sale?

A: We offer industrial wedge wire screens in various configurations including flat panels, cylindrical baskets, and curved sieves. All products feature precision laser-welded V-shaped wires and customizable slot sizes. Options suit applications in dewatering, filtration, and sizing.

Q: Why choose your well screens for sale over alternatives?

A: Our corrosion-resistant well screens feature continuous slot designs that prevent clogging while maximizing water flow. Constructed from stainless steel or PVC, they're engineered for superior sediment control and extended lifespan in groundwater applications. Custom diameters and slot sizes ensure optimal well performance.

Q: How does your flip flow screen for sale handle sticky materials?

A: Our flip flow screens use flexible polyurethane mats that generate high-frequency vibrations to prevent blinding. This elastic throwing motion effectively screens high-moisture, viscous materials like MSW and compost without clogging. Self-cleaning mechanisms maintain consistent throughput in challenging screening operations.

Q: What size specifications are available for wedge wire screens?

A: Wedge wire products feature customizable slot openings from 25 microns to 50mm to match your separation requirements. Panel dimensions typically range from 300mm to 2500mm in width/length, with cylinder diameters tailored to processing needs. Wire thickness and screen geometries are engineered for specific flow rates and material characteristics.

Q: Can these screens be customized for unique applications?

A: Yes, all three screen types offer tailored solutions including material grades (304/316 stainless steel), slot profiles (inlet/outlet variations), and connection systems. Custom fabrication includes non-standard sizes, special curves for equipment retrofits, and reinforced edges for high-pressure environments. Engineering support ensures optimal configuration for your specific process requirements.