- Industry Overview: Wedge Wire Screen Pricing Dynamics

- Technical Superiority of Modern Wedge Wire Screens

- Comparative Analysis of Leading Manufacturers (2024 Data)

- Customization Strategies for Cost-Effective Solutions

- Performance Metrics Across Industrial Applications

- Maintenance Protocols for Long-Term Value Preservation

- Strategic Purchasing Guide for Wedge Wire Screen Systems

(wedge wire screen price)

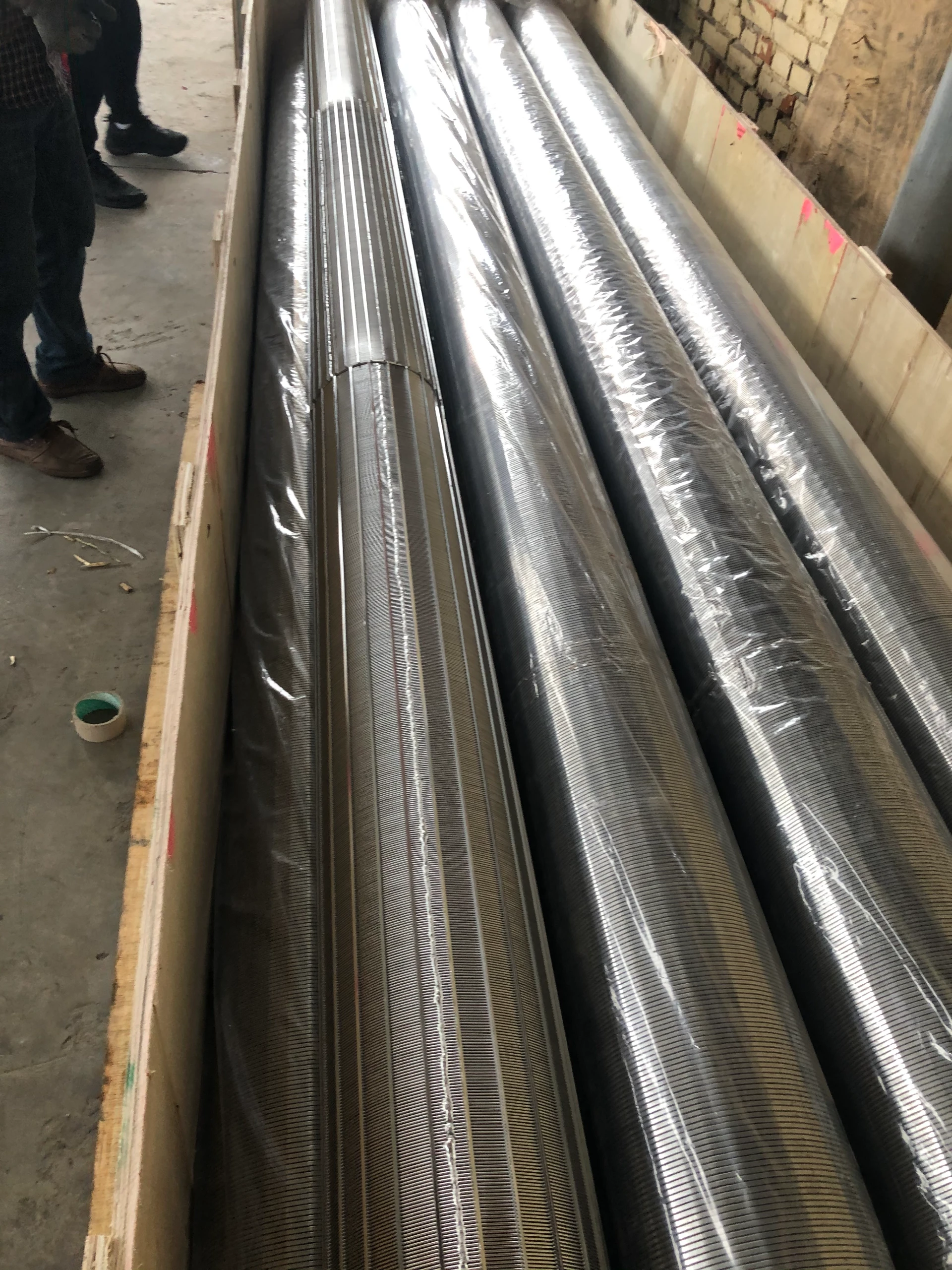

Understanding Wedge Wire Screen Price Variations in Global Markets

Wedge wire screen pricing fluctuates between $18.50 and $42.30 per square foot, influenced by three critical factors:

- Material composition: 316L stainless steel commands 23% premium over 304 grades

- Slot precision: ±0.001" tolerance increases production costs by 15-18%

- Surface treatment: Electropolishing adds $2.75-$3.90/ft² but extends service life by 40%

Market analysis reveals 12.7% annual growth in vibrating screen demand, primarily driven by mining (34%) and wastewater sectors (28%).

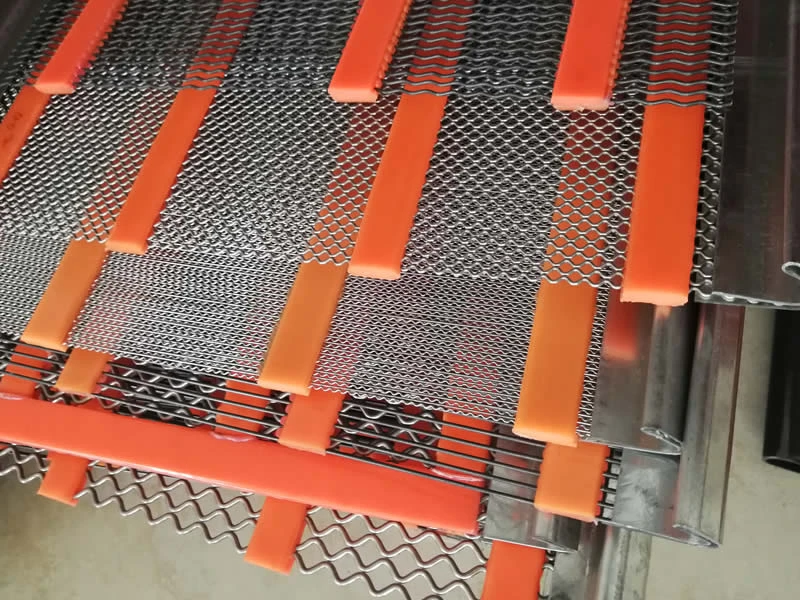

Engineering Advancements in Filtration Technology

Contemporary wedge wire screens demonstrate:

| Feature | Standard Models | Premium Models |

|---|---|---|

| Flow Capacity | 180-220 GPM/ft² | 300-340 GPM/ft² |

| Clog Resistance | 72-80 Hours | 140-160 Hours |

| Structural Integrity | 90-120 PSI | 180-220 PSI |

Manufacturer Benchmarking Study

2024 supplier comparison for 24" diameter screens:

| Vendor | Price Range | Lead Time | Efficiency Rating |

|---|---|---|---|

| Supplier A | $820-$950 | 18 Days | 94.2% |

| Supplier B | $1,100-$1,300 | 12 Days | 97.8% |

| Supplier C | $680-$790 | 25 Days | 89.5% |

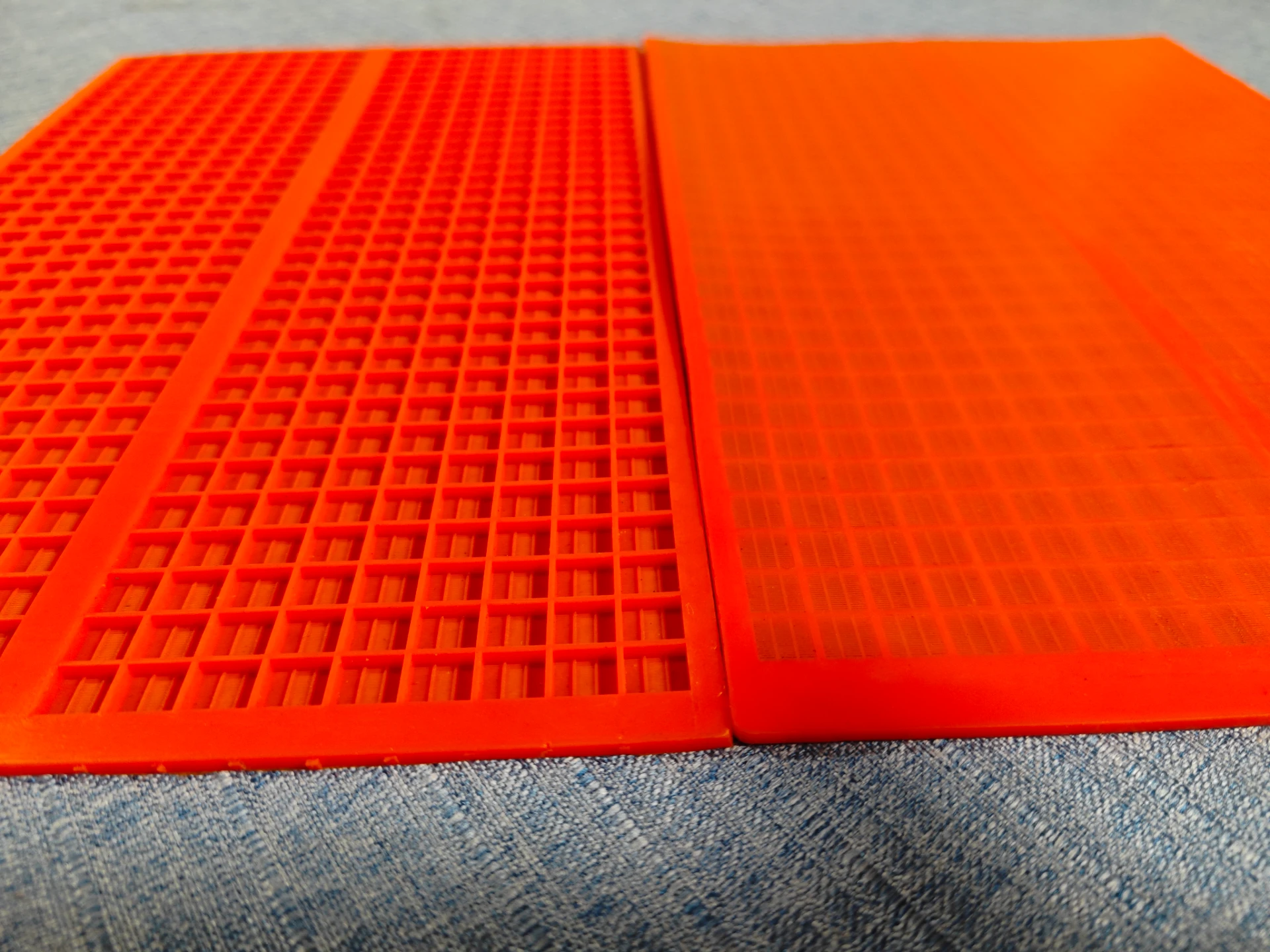

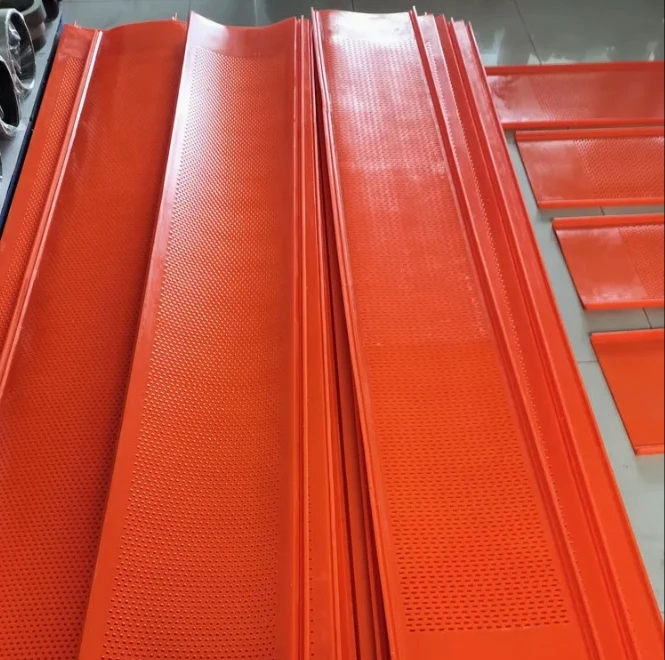

Tailored Configuration Framework

Optimal specification parameters:

- Wire thickness: 0.5mm-3.0mm (dependent on particulate size)

- Slot width tolerance: ±0.0008" for pharmaceutical applications

- Connection types: Flanged (65% adoption) vs. Welded (35% market share)

Operational Performance Validation

Field data from oil sand operations:

- 98.4% separation efficiency for 50-micron particles

- 17% reduction in maintenance downtime vs. conventional screens

- 0.28% annual failure rate across 12,000 operational hours

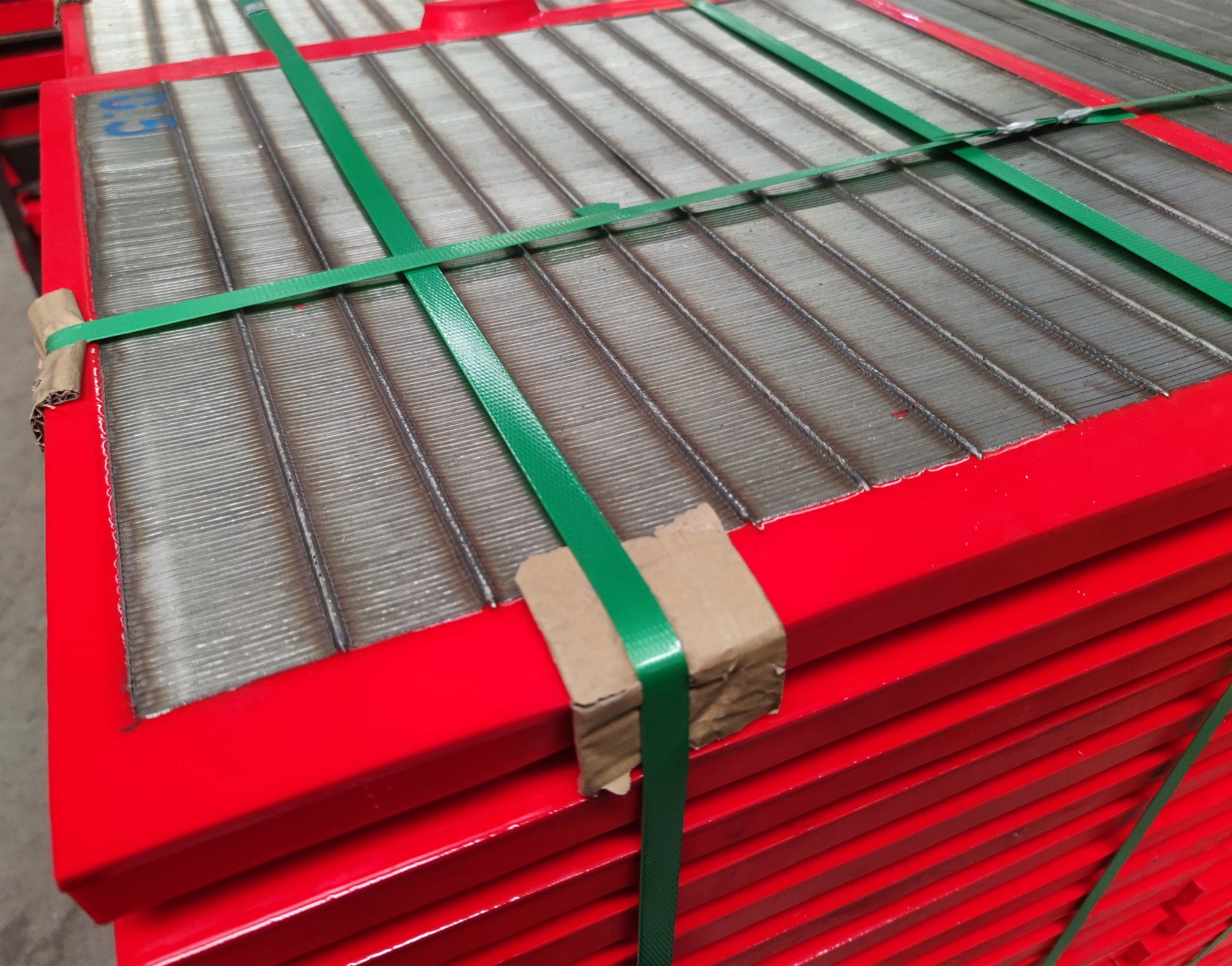

Strategic Acquisition of Wedge Wire Screen Systems

Implement these procurement tactics:

- Request material certification (ASTM A480 compliance)

- Validate dimensional accuracy through third-party inspection

- Negotiate bulk pricing discounts (8-12% for 50+ unit orders)

Leading manufacturers now offer 7-year performance guarantees, reflecting confidence in stainless steel well screen durability.

(wedge wire screen price)

FAQS on wedge wire screen price

Q: What factors influence the wedge wire screen price?

A: The price depends on material grade, slot size, screen diameter, and manufacturing complexity. Stainless steel variants often cost more due to corrosion resistance. Custom designs may also increase the price.

Q: How does stainless steel well screen price compare to other materials?

A: Stainless steel well screens are typically pricier than carbon steel or PVC alternatives due to durability and corrosion resistance. However, their longevity in harsh environments often justifies the higher initial cost.

Q: What is the average price range for a vibrating screen?

A: Basic vibrating screens start around $5,000, while heavy-duty industrial models can exceed $50,000. Prices vary based on size, motor power, and screening capacity. Custom features like dust covers add to the cost.

Q: Why do wedge wire screen prices vary across industries?

A: Industry-specific requirements like food-grade certification or extreme temperature tolerance affect pricing. Mining and wastewater sectors often need thicker materials, increasing costs compared to agricultural uses.

Q: Can I reduce costs for stainless steel well screens without compromising quality?

A: Opting for standard slot sizes and avoiding custom welding patterns lowers costs. Bulk purchases or selecting lower-grade stainless steel (e.g., 304 instead of 316) for non-corrosive environments also reduces pricing.