- Introduction to primary filtration mechanisms

- Technical specifications and operational benefits

- Performance comparison across leading manufacturers

- Customizable designs for industrial requirements

- Real-world implementation scenarios

- Maintenance protocols and lifecycle analysis

- Future trends in solid separation technology

(bar screens in wastewater treatment)

Essential first-line defense in liquid-solid separation

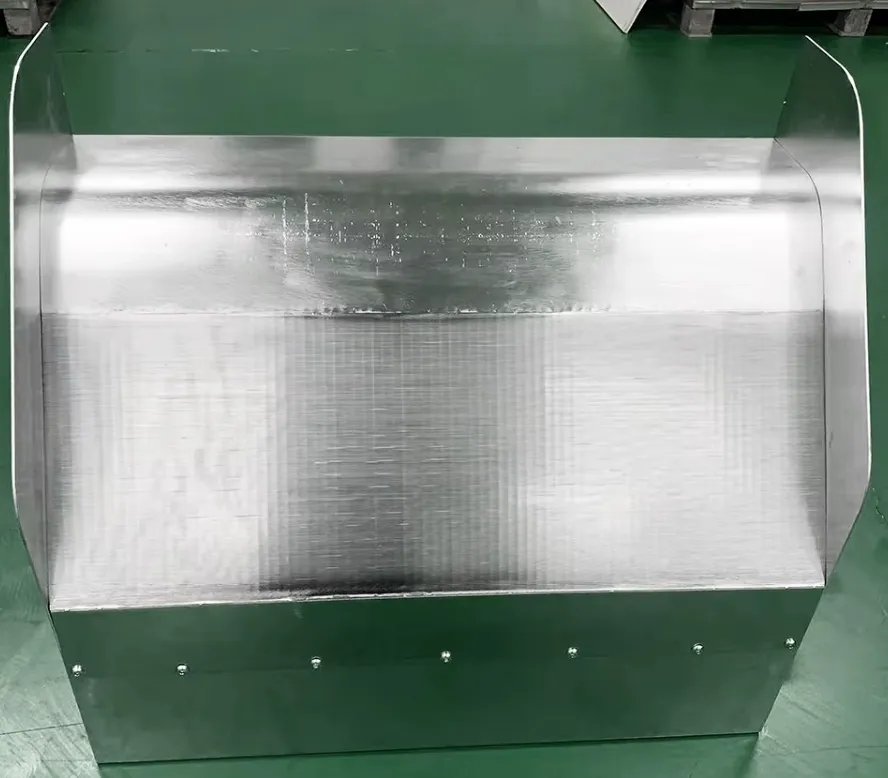

Bar screens in wastewater treatment serve as the initial physical barrier, removing large solids from influent streams. These coarse filtration systems capture debris ranging from 6 mm to 100 mm in size, protecting downstream equipment from damage. Modern installations handle flow rates up to 40,000 m³/day with removal efficiencies exceeding 95% for particles above 25 mm.

Engineering superiority in contaminant removal

Advanced wastewater bar screen models feature:

- Automated self-cleaning mechanisms reducing manual intervention by 80%

- Corrosion-resistant materials (316L stainless steel or duplex alloys) with 25+ year service life

- Integrated overflow protection maintaining operations during peak flows

- Real-time monitoring systems tracking removal efficiency and throughput

Industrial leader performance metrics

| Manufacturer | Bar Spacing (mm) | Max Flow (m³/s) | Cleaning Cycle (min) | Power Consumption (kW) |

|---|---|---|---|---|

| JWC Environmental | 6-50 | 5.2 | 15-60 | 1.8-4.5 |

| Huber Technology | 10-75 | 6.8 | 30-120 | 2.2-5.1 |

| Sulzer | 12-100 | 4.9 | 20-90 | 1.5-3.8 |

Adaptive configurations for specific applications

Customization parameters include:

- Screen angle: 30°-85° inclination adjustments for optimal solids capture

- Material selection: Carbon steel to titanium alloy options

- Automation integration: PLC controls with SCADA compatibility

- Safety features:

Municipal and industrial deployment cases

Case Study 1: A 500,000 PE (Population Equivalent) plant reduced pump maintenance frequency by 60% after installing 20mm spaced bar screens with automatic raking systems. Case Study 2: Food processing facility achieved 30% energy savings through variable-speed drive integration on their 50mm coarse screens.

Operational longevity optimization strategies

Preventive maintenance schedules extend equipment lifespan beyond manufacturer guarantees:

- Bi-weekly lubrication cycles for mechanical components

- Quarterly alignment checks on rake mechanisms

- Annual structural integrity assessments

Innovations redefining coarse screen functionality

Emerging technologies in wastewater bar screen design incorporate AI-powered debris recognition systems that adjust cleaning frequency based on real-time solids loading. New composite materials demonstrate 40% higher wear resistance than traditional stainless steel while reducing weight by 25%.

(bar screens in wastewater treatment)

FAQS on bar screens in wastewater treatment

Q: What is the primary function of bar screens in wastewater treatment?

A: Bar screens remove large debris like sticks, rags, and plastics from incoming wastewater. This protects downstream equipment from damage and prevents clogging in treatment processes.

Q: How does a wastewater bar screen differ from other screening devices?

A: Wastewater bar screens use vertical or inclined metal bars with specific spacing to trap coarse solids. They are typically the first line of defense, unlike finer screens that capture smaller particles later in the process.

Q: Why are coarse screens important in wastewater treatment plants?

A: Coarse screens act as a preliminary filtration step, intercepting bulky materials before they enter pumps or treatment units. This reduces maintenance costs and ensures smoother operation of subsequent processes.

Q: What maintenance is required for bar screens in wastewater systems?

A: Regular cleaning of accumulated debris and inspection for bar damage or corrosion are essential. Automated rakes or manual cleaning methods are often used to maintain efficiency.

Q: Where are bar screens typically installed in wastewater treatment facilities?

A: Bar screens are installed at the headworks of treatment plants, where raw wastewater first enters. This placement ensures early removal of large solids before primary treatment stages begin.