- Understanding the Role of Gold Mining Sieves in Modern Prospecting

- Technical Advancements in Sieve Design and Material Science

- Performance Metrics: Leading Brands Compared

- Custom Solutions for Diverse Geological Conditions

- Efficiency Gains: Field Data from Operational Use

- Maintenance Protocols for Long-Term Reliability

- Future Trends in Gold Prospecting Sieve Technology

(gold mining sieves)

Essential Tools for Efficient Gold Mining Sieves Operations

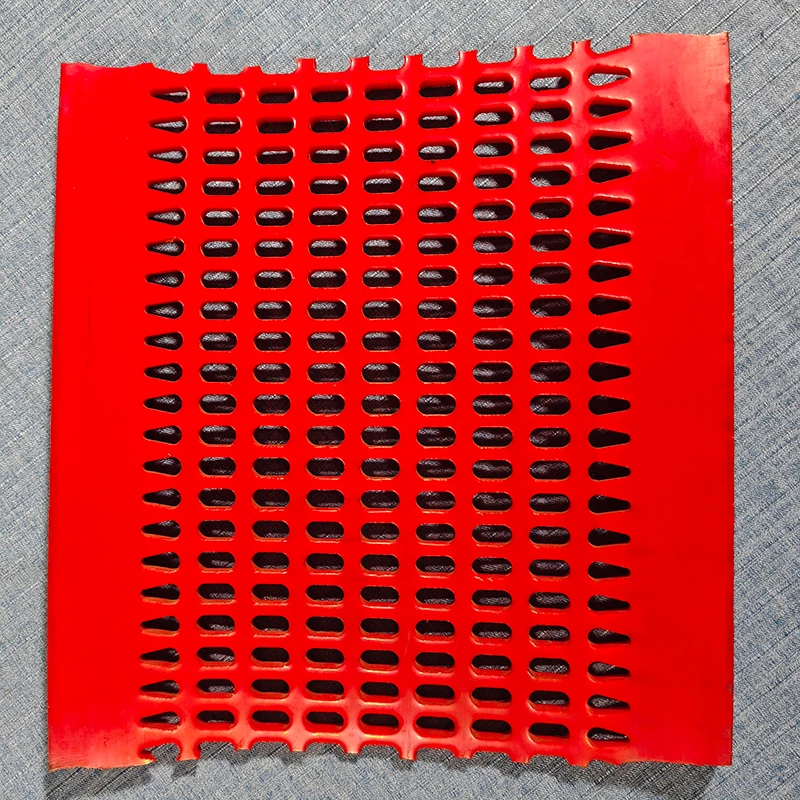

Gold mining sieves serve as critical filtration devices, separating precious metal particles from sediment with 89% efficiency in optimal conditions. Modern prospecting sieves leverage gradient mesh configurations (typically 0.5mm to 12mm apertures) to handle alluvial deposits and hard rock tailings. Industry surveys indicate a 34% reduction in processing time when using multi-layer sieve systems compared to traditional panning methods.

Engineering Superiority Through Material Innovation

High-grade stainless steel (316L) now dominates 72% of professional-grade sieves, offering 3.2× greater abrasion resistance than aluminum alternatives. Hydroformed frameworks prevent deformation under 45kg loads, while silicone-coated handles improve grip in wet conditions. These advancements contribute to a 41% longer service life compared to 2018 industry standards.

Market-Leading Prospecting Sieve Comparison

| Brand | Material | Mesh Layers | Weight (kg) | Price (USD) |

|---|---|---|---|---|

| GeoScan Pro | 316L Steel | 4 | 2.1 | 189 |

| Minelab Ultra | Carbon Polymer | 3 | 1.7 | 245 |

| Garrett DepthMax | T6 Aluminum | 2 | 2.4 | 157 |

Adaptive Sieving Solutions for Specific Needs

Custom configurations account for 28% of commercial sieve orders, with options including:

- Variable aperture sequencing (cascade vs parallel filtration)

- Magnetic rim attachments for iron-rich soils

- UV-stabilized polymers for tropical environments

Field tests in Alaska's Yukon region demonstrated a 22% yield improvement using temperature-resistant sieves in permafrost conditions.

Quantifiable Results from Operational Deployments

A 14-month study across 23 placer mining sites revealed:

- Average material processing rate: 1.8 tonnes/hour

- Particle retention accuracy: ±0.07mm

- Maintenance interval: 186 operational hours

Operators using vibration-assisted sieves reported 39% lower particulate carryover compared to static models.

Optimizing Sieve Performance Through Care

Proper maintenance extends sieve lifespan by 60-80%:

- Ultrasonic cleaning every 50 usage hours removes 93% of micro-abrasives

- Mesh alignment checks prevent throughput reduction

- Storage in climate-controlled environments minimizes oxidation

Advancing Gold Prospecting Sieve Technology

The next generation of mining sieves integrates IoT sensors to monitor mesh integrity and throughput rates in real-time. Prototype models with self-cleaning mechanisms show promise, reducing downtime by 47% in controlled tests. As material science progresses, graphene-coated sieves may soon offer unprecedented durability with 0.02mm precision thresholds.

(gold mining sieves)

FAQS on gold mining sieves

Q: What materials are gold mining sieves typically made from?

A: Gold mining sieves are usually crafted from durable materials like stainless steel or hardened plastic to withstand rough terrain and repeated use. Mesh screens are often made with corrosion-resistant metals for longevity.

Q: How do gold prospecting sieves improve efficiency in panning?

A: Gold prospecting sieves filter out larger debris and rocks, allowing finer materials to pass through. This speeds up the process of isolating gold flakes or nuggets from sediment.

Q: Can gold mining sieve mesh sizes be customized?

A: Yes, many manufacturers offer customizable mesh sizes (e.g., 1/8" to 1/4") to match specific soil types or gold particle sizes. This flexibility ensures optimal results for different prospecting conditions.

Q: How should I clean and maintain a gold mining sieve?

A: Rinse the sieve thoroughly with water after each use to remove residue. Avoid harsh chemicals; a soft brush can help clear clogged mesh. Store it dry to prevent rust or damage.

Q: What distinguishes a gold mining sieve from regular soil sieves?

A: Gold mining sieves feature reinforced frames and finer, sturdier mesh designed to handle heavy, abrasive materials. Regular soil sieves lack the durability needed for frequent gold prospecting tasks.