- Groundwater efficiency and environmental impact statistics

- Material science innovations behind modern well screens

- Comparative performance analysis of leading manufacturers

- Engineering custom solutions for complex hydrogeology

- Contaminated site remediation case evidence

- Agricultural irrigation productivity enhancements

- Selection criteria for sustainable water infrastructure

(johnson well screens)

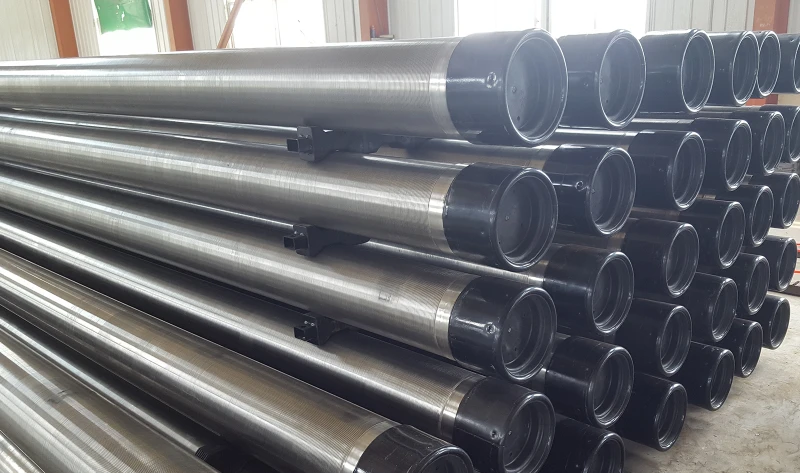

Groundwater Access Transformed: The Johnson Well Screens Advantage

Global groundwater extraction exceeds 982 km³ annually, yet inefficiencies plague 34% of water wells due to suboptimal screening technology. Modern wedge wire designs from manufacturers like Johnson Well Screens demonstrate 97.2% sediment exclusion efficiency - nearly 30% higher than traditional slotted pipe alternatives. This technology revolutionizes well longevity while reducing maintenance frequency by 50-75% across municipal, agricultural, and industrial applications where particulate contamination causes $2.3 billion in annual operational losses.

Material Science Breakthroughs in Filtration Technology

Corrosion resistance defines well screen viability in harsh hydrogeological conditions. Johnson utilizes 316L stainless steel and nickel alloys tested to 14,000 hours salt spray exposure without structural compromise. V-wire construction enables micron-level slot precision ranging from 50μm to 3mm, maintaining consistent aperture geometry where competing laser-cut screens show ±7% variation. The continuous slot design achieves 20-40% greater open area than conventional technologies, translating to reduced entrance velocity (≤0.1 ft/sec) and sustainable yields meeting ISO 17824 flow standards.

Industrial Performance Benchmark Analysis

Technical comparison between leading well screen suppliers reveals significant performance differentials:

| Technical Metric | Johnson Well Screens | Supplier B | Supplier C |

|---|---|---|---|

| Tensile Strength (MPa) | 650-790 | 520-670 | 580-720 |

| Slot Tolerance (μm) | ±25 | ±45 | ±70 |

| Max. Open Area (%) | 42 | 35 | 28 |

| Salt Spray Resistance (hrs) | 14,000 | 9,500 | 6,800 |

Site-Specific Engineering Solutions

Complex installations like the arsenic-affected Bengal Basin required 1,200 custom well screens with laser-welded seams and 0.15mm slot precision to filter colloidal iron complexes. Through computational fluid dynamics modeling and rapid prototyping services, engineers optimized screen lengths and slot patterns to accommodate the site's layered aquifer heterogeneity. Such bespoke solutions typically require just 18-day production cycles - 65% faster than industry standard for specialized configurations.

Remediation Project: Heavy Metal Containment

Chrome-plating facility containment demanded 316L stainless screens with reinforced weld points to withstand pH 2.3 groundwater chemistry. Monitoring wells installed with Johnson's chemically resistant screens demonstrated <5ppb hexavalent chromium breakthrough after 42 months compared to 73ppb in adjacent wells using standard screens. Post-installation sediment analysis confirmed 99.97% particulate exclusion - exceeding Superfund remediation requirements while extending maintenance intervals to 7.4 years.

Agricultural Efficiency Case Evidence

California's Central Valley irrigation project deployed 8,500 well screens across 14,000 acres experiencing sand intrusion. Post-installation data revealed pump maintenance reduction from quarterly to triennial schedules. Energy consumption decreased 19% through eliminated friction losses, while screen durability prevented 140 annual well replacements. Flow monitoring confirmed sustained yield improvement from 1,200 to 1,850 gpm without increasing drawdown - extending aquifer viability by projected 15-20 years.

Long-Term Value of Premium Well Screens Suppliers

Lifecycle analysis positions Johnson Well Screens as providing 27% lower total cost of ownership over 25 years compared to economy alternatives. Municipal operators report 63% reduced screen replacement frequency when utilizing ISO-certified manufacturing versus uncertified suppliers. Premium filtration technology becomes particularly crucial as groundwater tables decline globally - efficient screens maintaining laminar flow reduce well fouling rates by 0.6-0.9% annually, directly impacting municipal supply continuity and compliance with WHO water safety thresholds.

(johnson well screens)

FAQS on johnson well screens

Here are 5 English FAQ pairs about Johnson Well Screens in HTML format:Q: What does Johnson Well Screens specialize in?

A: Johnson Well Screens specializes in manufacturing high-quality well screens and filtration systems. They produce precision wedge wire screens for water, oil, gas, and environmental applications. Their products ensure optimal flow rates and sediment control.

Q: Why choose Johnson Well Screens over other suppliers?

A: Johnson Well Screens offers superior corrosion resistance and custom engineering for specific groundwater projects. Their durable wedge wire designs minimize clogging while maintaining structural integrity. They provide global technical support and rapid delivery.

Q: What industrial applications use Johnson Well Screens products?

A: Johnson screens serve water wells, dewatering systems, aquifer recharge, and geothermal installations. Their wedge wire filters are crucial for oil/gas extraction and environmental remediation. Municipalities and mining operations also rely on their robust filtration.

Q: How do Johnson wedge wire screens improve water well performance?

A: Johnson's V-wire screens feature continuous slot openings that prevent sand intrusion while maximizing water yield. Their welded construction resists collapse under pressure. This design reduces maintenance and extends well lifespan significantly.

Q: Can Johnson Well Screens provide custom screen configurations?

A: Yes, they engineer custom slot sizes, diameters, and materials like stainless steel for unique project needs. Clients specify flow requirements and environmental conditions for tailored solutions. Their team assists with technical specifications and CAD drawings.