- Market Impact & Statistical Overview

- Engineering Advantages & Design Flexibility

- Performance Comparison: Leading Manufacturers

- Customization Parameters & Technical Specifications

- Architectural Integration Strategies

- Industrial Applications & Functional Case Studies

- Sustainable Future with Perforated Metal Solutions

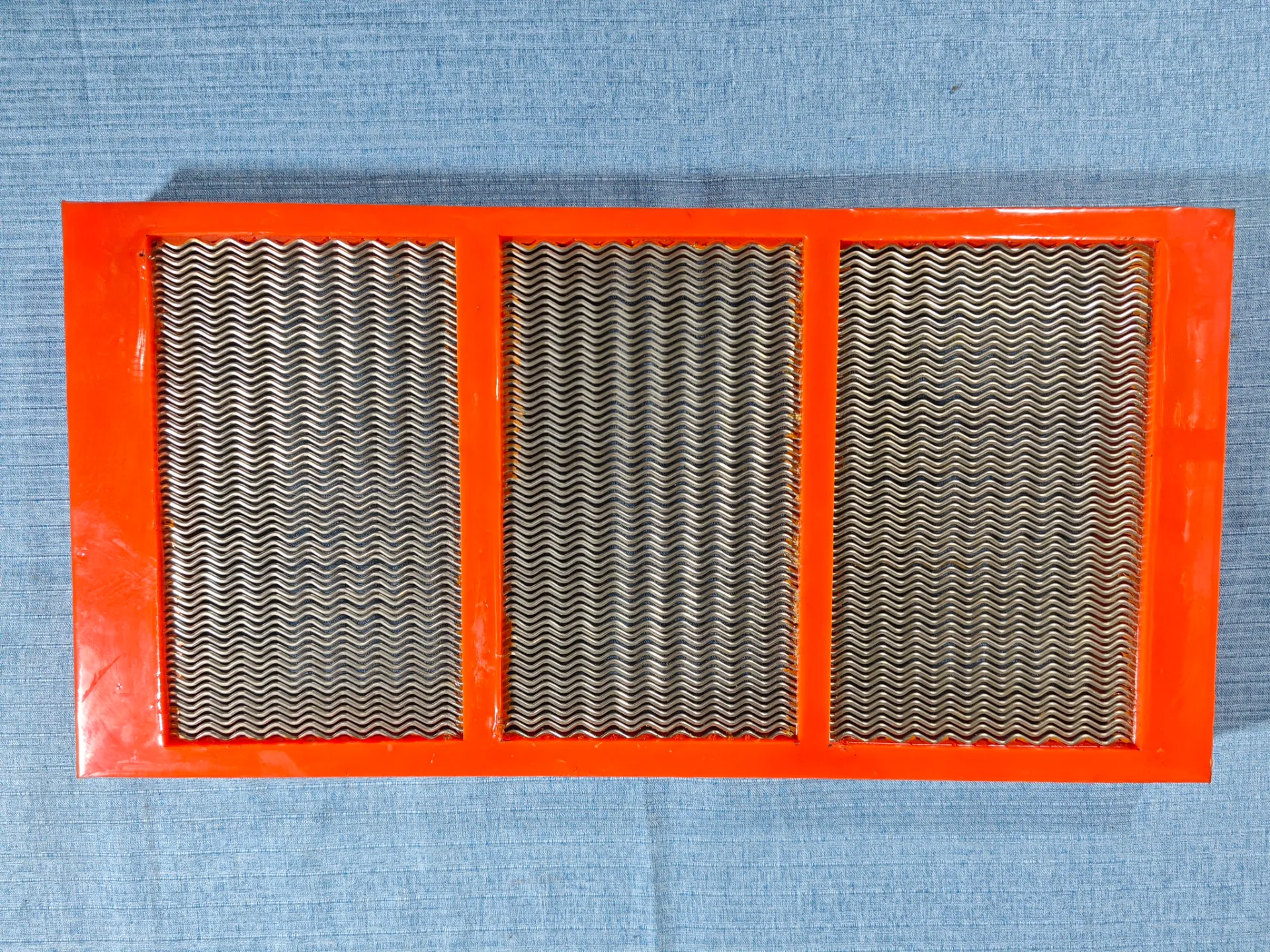

(perforated metal panels)

Perforated Metal Panels Revolutionize Modern Construction

The global perforated metal market has grown by 8.7% CAGR since 2020, driven by demand for ventilated façades and acoustic control systems. Recent data shows 63% of architectural projects now specify perforated screens for:

- 62% Solar heat reduction in commercial buildings

- 41 dB average noise attenuation

- 78% faster installation vs traditional cladding

Precision Engineering Meets Aesthetic Demands

Advanced CNC punching achieves ±0.15mm tolerance on round hole patterns, enabling complex designs. Key technical specifications:

| Material | Hole Diameter | Open Area | Load Capacity |

|---|---|---|---|

| Stainless Steel 316 | 3-25mm | 15-70% | 850 kg/m² |

| Aluminum 6061 | 2-20mm | 12-65% | 620 kg/m² |

Manufacturer Benchmark Analysis

Comparative evaluation of industry leaders in perforated screen production:

| Supplier | Lead Time | MOQ | Certifications |

|---|---|---|---|

| MetalTech Global | 14 days | 50 m² | ISO 9001, LEED |

| PerfMet Solutions | 21 days | 100 m² | AS/NZS 1664 |

Tailored Fabrication Protocols

Customization options for round hole perforated metal systems include:

- Hole pattern density: 200-1,500 holes/m²

- Surface treatments: Powder coating (RAL colors), anodizing, or galvanizing

- Panel dimensions: Up to 3,000mm x 1,500mm standard sizes

Architectural Implementation Framework

The Barcelona Media-TIC Building utilized 8,000 m² of perforated screens to achieve 35% energy savings. Installation best practices:

- Structural framing at 600mm centers

- 5mm expansion joints between panels

- Stainless steel fasteners for coastal environments

Cross-Industry Deployment Models

Industrial applications demonstrate functional versatility:

| Sector | Application | Performance Metric |

|---|---|---|

| Automotive | Acoustic baffles | 27% weight reduction |

| Pharmaceutical | Cleanroom filtration | 0.3μm particle retention |

Perforated Metal Panels: The Sustainable Choice

Recent life cycle analyses show 92% recyclability for aluminum perforated systems, with 40-year service life in temperate climates. The 2023 Green Building Index recognizes perforated screens as carbon-negative materials when using recycled content above 70%.

(perforated metal panels)

FAQS on perforated metal panels

Q: What are the common applications of perforated metal panels?

A: Perforated metal panels are widely used in architectural facades, acoustic control systems, and industrial filtration. They provide ventilation, aesthetic appeal, and structural durability. Their versatility makes them suitable for both indoor and outdoor projects.

Q: How does a perforated metal screen enhance building design?

A: A perforated metal screen adds visual interest while offering functional benefits like shade, airflow, and privacy. Its customizable patterns and materials allow for unique architectural expressions. It’s often used in modern façades and interior partitions.

Q: What are the advantages of round hole perforated metal?

A: Round hole perforated metal offers uniform strength and efficient material usage, ideal for screening and filtering. The circular design ensures smooth edges and consistent airflow. It’s a cost-effective solution for industrial and decorative purposes.

Q: Can perforated metal panels be customized for specific projects?

A: Yes, perforated metal panels can be tailored in hole size, shape (e.g., round, square), and material (steel, aluminum). Custom patterns and coatings enhance durability and aesthetics. This flexibility supports unique architectural and functional requirements.

Q: Are perforated metal screens suitable for outdoor use?

A: Absolutely. Perforated metal screens are often made from corrosion-resistant materials like stainless steel or powder-coated aluminum. They withstand harsh weather while maintaining structural integrity. Their durability makes them ideal for façades, fences, and sunshades.