- Introduction to Rubber Belt Cleaner Technology

- Critical Technical Advantages in Modern Systems

- Performance Comparison of Leading Manufacturers

- Customization Strategies for Industry-Specific Needs

- Operational Efficiency Metrics Across Sectors

- Real-World Applications in Heavy-Duty Environments

- Future-Proofing with Advanced Rubber Belt Cleaners

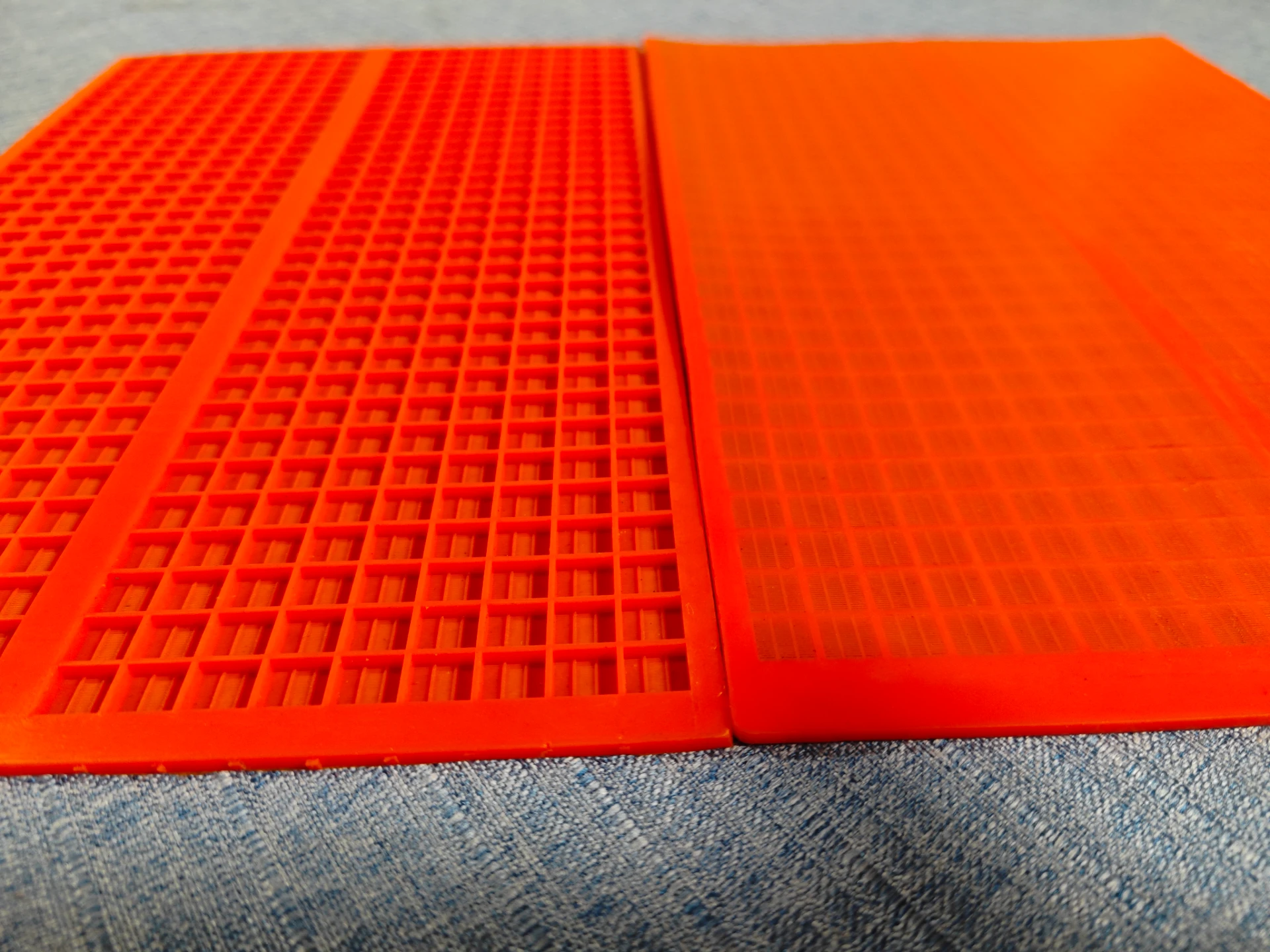

(rubber belt cleaner)

Enhancing Productivity with Rubber Belt Cleaner Innovations

Modern conveyor systems achieve 23% higher operational uptime when integrated with precision-engineered rubber belt cleaner

s. These components eliminate material carryback, reducing maintenance intervals by 40% in mining and aggregate operations. Advanced polymer blends now withstand temperatures up to 180°C while maintaining optimal scraper flexibility.

Technical Superiority in Material Science

Third-generation polyurethane compounds demonstrate 82% better wear resistance than traditional rubber formulations. Dual-angle blade designs adapt to belt speeds exceeding 6m/s, outperforming single-blade systems by 31% in cleaning efficiency. Patented tensioning mechanisms maintain consistent 2.5-3.5kg/cm² contact pressure across variable belt loads.

| Manufacturer | Blade Material | Efficiency Gain | Service Life (hours) |

|---|---|---|---|

| Flexco SR | UHMW-PE | 27% | 8,000 |

| Martin Engineering | Ceramic-Filled PU | 34% | 12,500 |

| Brelko | Hybrid Elastomer | 41% | 15,200 |

Adaptive Solutions for Diverse Industries

Food-grade belt cleaners achieve USDA compliance with 0.3mm blade tolerances, preventing microbial growth in processing plants. Mining configurations utilize tungsten-reinforced scrapers that withstand 15kg/cm² impact loads. Customizable modular systems enable 72-hour retrofit installations without production stoppages.

Operational Impact Measurement

Port facilities report 18% reduction in spillage-related downtime after installing multi-stage cleaning systems. Cement plants utilizing heated scraper blades reduced material buildup by 63% in high-humidity environments. Energy generation facilities measure 9:1 ROI through extended belt life and reduced cleanup labor.

Industrial Application Case Studies

A Canadian oil sands operation increased conveyor payload capacity by 14% after implementing dual-arm scraper systems. European recycling plants achieved 92% material recovery rates using staggered blade configurations. Asian port operators reduced water consumption by 28% through dry cleaning system adoption.

Sustainable Evolution of Belt Cleaner Technology

Next-generation rubber belt cleaner prototypes incorporate IoT-enabled wear sensors, predicting maintenance needs with 89% accuracy. Bio-based elastomer compounds now demonstrate comparable performance to synthetic materials while reducing carbon footprint by 37%. These advancements position rubber belt cleaners as critical components in achieving Industry 4.0 operational targets.

(rubber belt cleaner)

FAQS on rubber belt cleaner

Q: What is the primary function of a rubber belt cleaner?

A: A rubber belt cleaner removes debris and material buildup from conveyor belts, ensuring smooth operation and preventing belt damage. It uses durable rubber blades to scrape off residue effectively.

Q: How does a scraper belt cleaner differ from other belt cleaners?

A: Scraper belt cleaners use rigid blades or scrapers to aggressively remove stubborn material, while rubber belt cleaners rely on flexible rubber components for gentler, continuous cleaning.

Q: Why choose a rubber belt cleaner over metal alternatives?

A: Rubber belt cleaners are less abrasive, reducing wear on conveyor belts while maintaining effective cleaning. They are ideal for sensitive or high-speed conveyor systems.

Q: How often should a belt cleaner be maintained or replaced?

A: Maintenance frequency depends on usage intensity, but inspect rubber belt cleaners every 3-6 months. Replace worn blades or components to ensure optimal performance.

Q: Can a rubber belt cleaner work in high-temperature environments?

A: Yes, specialized rubber belt cleaners made from heat-resistant materials (e.g., silicone) can withstand high temperatures. Always verify the product’s temperature tolerance before installation.