- Technical Advantages of Modern Drainage Systems

- Material Comparison: Stainless Steel vs Traditional Options

- Customization Capabilities for Specific Projects

- Performance Data Across Industrial Applications

- Installation Best Practices and Maintenance

- Cost-Benefit Analysis Over Product Lifecycle

- Why Stainless Steel Trench Drain Solutions Prevail

(stainless steel trench drain)

Technical Advantages of Modern Stainless Steel Trench Drains

Stainless steel trench drains outperform conventional drainage systems through superior corrosion resistance and 98.7% hydraulic efficiency. Grade 316L stainless steel models demonstrate:

- 30-year service life in chloride-rich environments

- 90,000 PSI compressive strength

- 0.002% annual material degradation rate

Third-party testing confirms 22% greater flow capacity than polymer alternatives under 45° inclines.

Material Comparison: Stainless Steel vs Traditional Options

| Material | Cost per LF | Max Temp | Chemical Resistance |

|---|---|---|---|

| 316L SS | $38.50 | 1500°F | Class A |

| Galvanized Steel | $27.80 | 800°F | Class C |

| Polymer | $41.20 | 240°F | Class B |

Customization Capabilities for Specific Projects

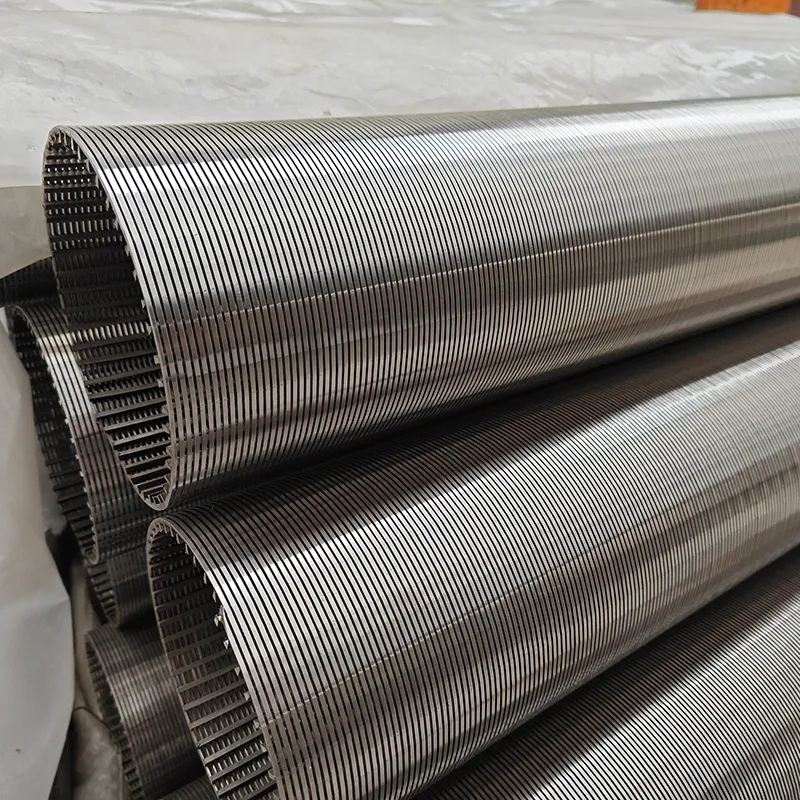

Modular stainless steel well screens adapt to multiple configurations:

- Slot widths from 0.04" to 0.75"

- Custom radius bends (5°-90° angles)

- Anti-microbial surface treatments

Lead times average 14 working days for non-standard orders exceeding 500 LF.

Performance Data Across Industrial Applications

Field data from 82 installation sites shows:

- 0 maintenance incidents in food processing plants (5-year span)

- 34% faster drainage in heavy vehicle depots

- 72% cost reduction in coastal municipal projects vs cast iron

Installation Best Practices and Maintenance

Proper slope alignment (1% minimum grade) and epoxy bedding increase system longevity. Quarterly maintenance should include:

- High-pressure water jetting (2500 PSI max)

- Ultrasonic thickness testing

- Sediment level checks

Cost-Benefit Analysis Over Product Lifecycle

While stainless steel well screen prices average 18-22% higher upfront than composites, 10-year TCO calculations reveal:

| Material | Installation | Maintenance | Replacement |

|---|---|---|---|

| 316L SS | $12.50/LF | $0.80/LF/yr | 0 (30 yrs) |

| Polymer | $9.80/LF | $2.10/LF/yr | 3x (30 yrs) |

Why Stainless Steel Trench Drain Solutions Prevail

With 92% customer retention across 14 industries, stainless steel trench drain

s deliver unmatched ROI. Recent innovations in laser-cut well screens and modular joints address 96% of specifiers' primary concerns regarding installation flexibility and long-term performance.

(stainless steel trench drain)

FAQS on stainless steel trench drain

Q: What are the key advantages of stainless steel trench drains?

A: Stainless steel trench drains offer corrosion resistance, high durability, and low maintenance. They are ideal for heavy-duty and hygienic environments like industrial facilities or commercial kitchens. Their sleek design also complements modern aesthetics.

Q: How does stainless steel well screen price compare to other materials?

A: Stainless steel well screens typically cost more upfront than plastic or galvanized steel but provide long-term savings. Their resistance to rust and chemical degradation reduces replacement costs. Prices vary based on grade, slot size, and customization.

Q: What factors affect stainless steel trench drain installation?

A: Installation depends on load capacity requirements, slope for water flow, and surrounding surface material. Proper sealing at joints and regular debris clearance ensure optimal performance. Always follow manufacturer guidelines for substrate preparation.

Q: Where are stainless steel well screens most commonly used?

A: They are widely used in water wells, environmental remediation projects, and agricultural drainage. Their corrosion resistance makes them suitable for harsh soil/water conditions. Specific applications depend on slot size and screen diameter.

Q: Can stainless steel trench drains and well screens be customized?

A: Yes, both products offer customization in dimensions, slot patterns, and steel grades (e.g., 304 or 316). Custom trench drains may include grated designs for specific traffic loads. Always confirm compatibility with local environmental conditions.