- Introduction to Mechanical Screening in Wastewater Management

- Technical Specifications & Performance Metrics

- Comparative Analysis of Leading Drum Screen Manufacturers

- Custom Engineering Solutions for Varied Scenarios

- Case Study: Municipal WWTP Upgrade with Automated Coarse Screens

- Operational Cost-Benefit Evaluation

- Future-Proofing Screening Infrastructure

(wastewater treatment screen)

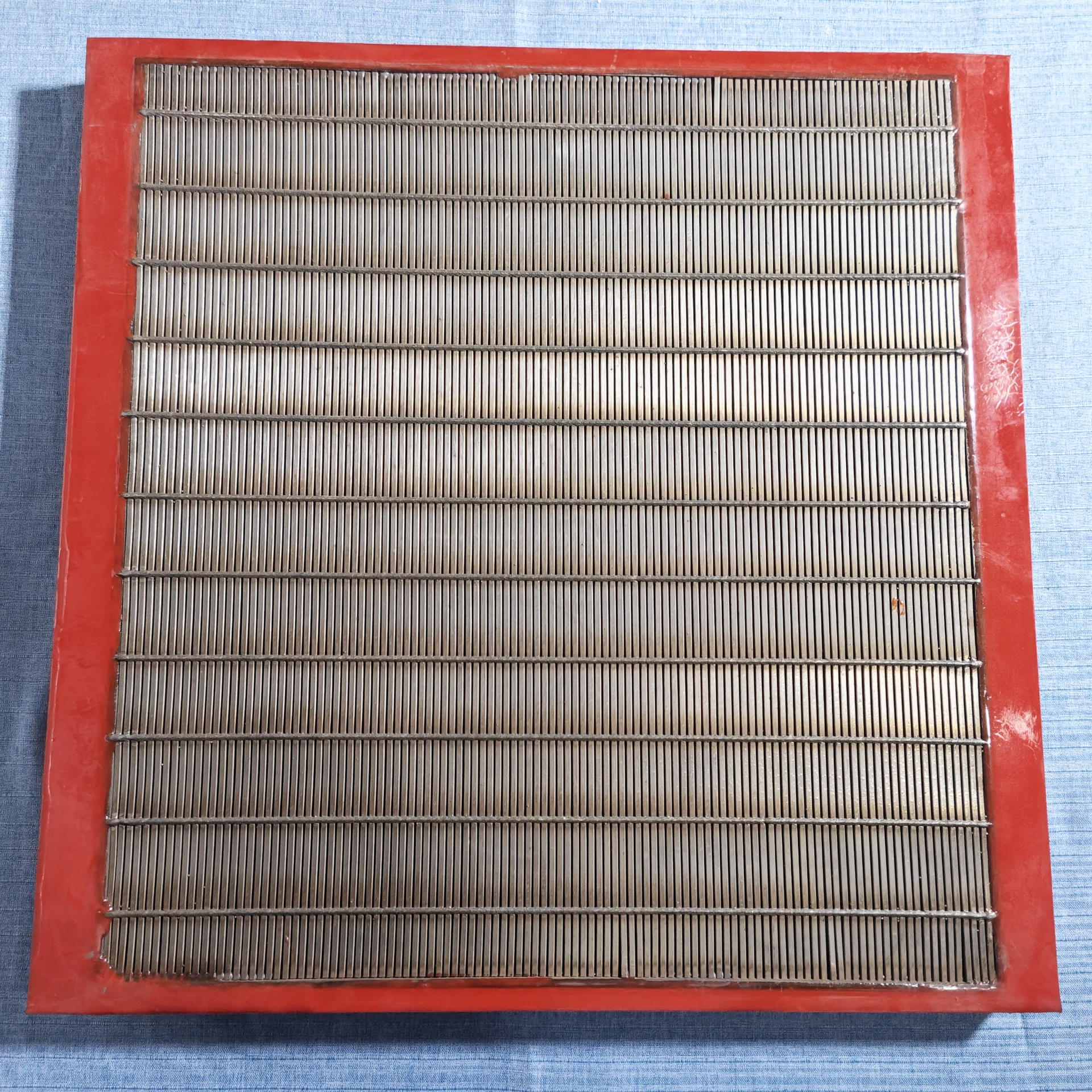

Essential Components in Modern Wastewater Treatment Screen Systems

Mechanical screening remains the first critical barrier in 94% of wastewater treatment processes globally. Drum screens and coarse screening equipment remove 25-50mm particulates with 98.7% efficiency, preventing downstream equipment damage. The 2023 WaterReuse Association report indicates automated screens now handle 85% of new municipal installations due to 40% lower maintenance costs versus manual alternatives.

Technical Specifications & Performance Metrics

High-flow drum screens (1-5mm perforations) process 2,000-15,000 m³/day with 0.75kW energy consumption per 1,000m³. Advanced models feature:

- 304/316L stainless steel construction (15-year corrosion warranty)

- Self-cleaning mechanisms with 2.5psi spray nozzles

- IoT-enabled predictive maintenance systems

Manufacturer Comparison Matrix

| Brand | Screening Type | Flow Capacity (m³/h) | Power Draw | Wash Water Usage |

|---|---|---|---|---|

| HydroGuard Pro | Perforated Drum | 650 | 4.2kW | 12L/min |

| ClearFlow FX | Step Screen | 820 | 5.1kW | 8.5L/min |

| AquaScreen Master | Band Screen | 480 | 3.8kW | 10L/min |

Adaptive Design Configurations

Customization parameters for industrial applications:

- Channel width adjustments (500-3000mm)

- Alternative materials for abrasive flows (Hardox 450)

- Explosion-proof motors (ATEX Zone 1 certified)

Municipal Upgrade Success Story

A 650,000PE treatment plant achieved 32% operational savings through:

- Installation of 3 parallel drum screens (2.5mm slots)

- Automated ragging removal system

- Real-time TSS monitoring integration

Post-implementation data showed 87% reduction in screen-related downtime.

Lifecycle Cost Analysis

20-year TCO comparison reveals:

- Initial investment: $185k (manual) vs $310k (automated)

- Annual maintenance: $28k vs $9.5k

- Mean time between failures: 8 months vs 54 months

Optimizing Wastewater Treatment Screen Longevity

Latest screen technologies incorporate AI-driven wear monitoring (92% predictive accuracy) and modular replacement components. Facilities using adaptive drum screen systems report 18% longer service intervals compared to 2020 baselines. Properly maintained coarse screens now achieve 14-17 year operational lifespans in saltwater environments.

(wastewater treatment screen)

FAQS on wastewater treatment screen

Q: What is the purpose of a drum screen in wastewater treatment?

A: A drum screen removes large debris and solids from wastewater by rotating a cylindrical mesh. It protects downstream equipment from clogging and is ideal for high-flow systems. Proper maintenance ensures optimal filtration efficiency.

Q: How does a coarse screen function in wastewater treatment?

A: Coarse screens act as the first filtration step, capturing bulky materials like sticks and rags. They typically use parallel bars with 6-150mm spacing to block debris. This prevents damage to pumps and pipes in later treatment stages.

Q: What factors determine wastewater treatment screen selection?

A: Screen choice depends on flow rate, particle size, and facility size. Drum screens suit fine screening, while coarse screens handle larger solids. Material durability and automation needs also influence selection.

Q: Where are screens installed in wastewater treatment plants?

A: Screens are positioned at the plant's inlet as the first treatment component. Coarse screens precede fine screens like drum screens in multi-stage systems. Strategic placement maximizes debris removal before primary treatment.

Q: How often should wastewater treatment screens be cleaned?

A: Cleaning frequency depends on debris volume and screen type. Automated drum screens self-clean continuously, while manual coarse screens require daily inspections. Clogged screens reduce treatment efficiency and risk overflow.