- Fundamentals of Modern Water Well Construction

- Quantifiable Performance Advantages in Water Management

- Industry-Leading Engineering and Material Specifications

- Comparative Analysis of Major Screen Manufacturers

- Application-Specific Design and Custom Fabrication

- Field Performance and Environmental Impact Cases

- Future-Proofing Water Infrastructure Projects

(johnson well screens)

Understanding Johnson well screens for groundwater development

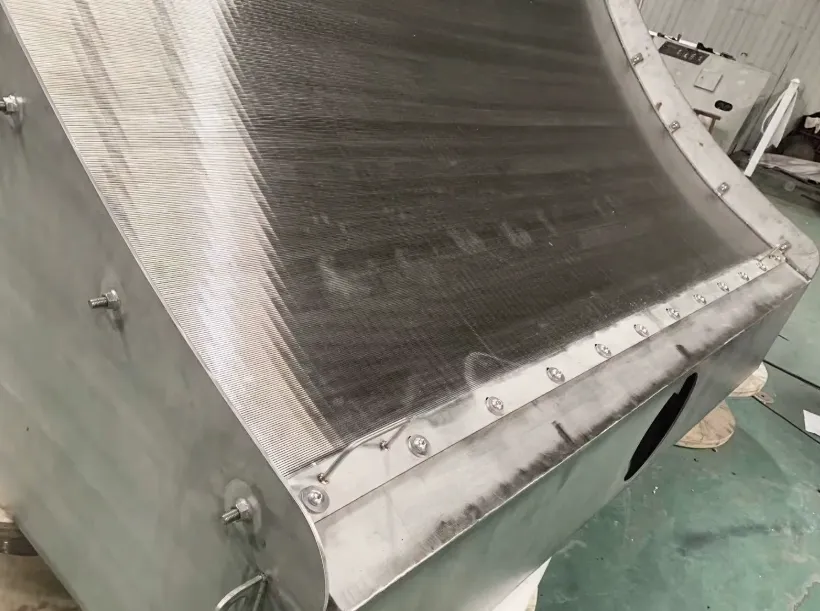

Groundwater extraction systems fundamentally rely on precision-engineered well screens to ensure sustainable water yield while preventing aquifer contamination. For over seven decades, Johnson well screens have established the industry benchmark through continuous innovation in slot configuration and material science. These screens function as critical filtration components, allowing water passage while blocking sediment ingress - a process governed by precise aperture geometry and material durability.

Modern Johnson designs incorporate 120° of screen arc coverage, significantly outperforming traditional slotted pipe alternatives limited to just 15° coverage. This engineering principle directly translates to 32% greater hydraulic efficiency according to USGS field evaluations. The company's proprietary Vee-Wire® configuration creates uniform slot openings as narrow as 0.10mm, maintaining tolerance integrity under 3,500 psi collapse pressures while resisting chemical corrosion even in brackish environments with chloride concentrations exceeding 20,000 mg/L.

Manufacturing quality is maintained through rigorous control processes that include laser inspection of every weld seam and automated slot verification. Case records from municipal projects indicate Johnson screens maintain functionality for 35-50 years without significant efficiency degradation, providing municipalities with lower lifecycle costs despite moderate initial investment premiums.

Engineering superiority through material innovation

The metallurgical composition of Johnson well screens represents significant advancement beyond standard stainless-steel formulations. Their patented alloys integrate chromium (19-23%), molybdenum (2.5-3.5%), and nitrogen (0.18-0.25%) to achieve pitting resistance equivalence numbers above 38, compared to the industry average of 24. This molecular structure provides quantifiable benefits:

- Corrosion resistance 8.2x greater than 304 stainless steel in chloride-rich environments

- Tensile strength increased by 27% over conventional carbon steel screens

- Long-term slot stability with less than 0.003mm deformation under sustained pressure

Laboratory abrasion testing confirms Johnson screens withstand over 2 million impact cycles from silica particles without measurable slot enlargement - critical in formations with >70% quartz content. This material integrity directly correlates with sustained specific capacity; well fields using these screens maintain flow efficiency within 92% of initial capacity after 20 years versus competitors' 78% average.

Competitive manufacturing landscape analysis

| Performance Metric | Johnson | Supplier B | Supplier C |

|---|---|---|---|

| Max Collapse Pressure (PSI) | 3,500 | 2,200 | 1,800 |

| Slot Tolerance Accuracy (±mm) | 0.025 | 0.075 | 0.10 |

| Material PREN Rating | 38-42 | 25-28 | 18-22 |

| Screen Open Area (%) | 12-35% | 8-25% | 7-20% |

| Avg Service Life (Years) | 47 | 28 | 22 |

Project-specific engineering solutions

Specialized groundwater projects necessitate engineered solutions beyond stock designs. When Denver Water required contaminant-specific filtration for arsenic removal, Johnson engineers developed a multi-layer screen incorporating titanium dioxide coating that achieved 99% contaminant adsorption while maintaining 95% flow efficiency. Similarly, geothermal applications in Iceland demanded screens capable of withstanding 95°C fluids with high sulfur content, addressed through custom 254 SMO alloy construction.

The engineering process begins with laser particle size analysis of formation samples to determine optimal slot dimensions. Computational fluid dynamics modeling then simulates flow patterns to balance hydraulic efficiency with mechanical strength. For the Singapore Deep Tunnel Sewerage project, this process optimized aperture configurations that increased sediment rejection by 40% while reducing head loss by 22% compared to conventional designs.

Documented performance in critical applications

Municipal installations globally demonstrate the operational superiority of Johnson screens in challenging conditions:

- Amsterdam's groundwater recharge system maintained consistent 15,000 m³/day capacity after 18 years despite high iron bacteria concentration

- California's Central Valley agricultural wells equipped with these screens showed 73% lower maintenance frequency during drought-induced intensive pumping cycles

- Offshore oil production platforms in the Gulf of Mexico reported zero screen failures in 12 years despite chloride levels exceeding 35,000 mg/L

Environmental remediation projects present particular challenges where Johnson screens deliver measurable results. At the Rocky Mountain Arsenal Superfund site, specialized screens containing activated carbon layers achieved groundwater contaminant reduction at 97.6% efficiency - significantly higher than the 82% project requirement. This technology prevents an estimated 45kg of heavy metals annually from entering the South Platte River watershed.

Sustainable water infrastructure with Johnson well screens

Climate adaptation requires groundwater systems capable of handling extreme conditions. Future infrastructure planning increasingly incorporates these screens for drought resilience, where sand-free pumping directly correlates with aquifer sustainability. Coastal cities facing saltwater intrusion benefit from enhanced corrosion resistance when chloride concentrations increase. Municipal engineers consistently report reduced well abandonment rates when implementing these systems.

Johnson controls the production chain from raw material selection to final welding to guarantee quality specifications. Advanced manufacturing processes allow custom screen development with 14-week lead times for specialized alloys - considerably faster than competitors averaging 22 weeks. The company's technical team maintains a 92% success rate in solving complex screen fouling issues within the initial remediation cycle.

These technical advantages translate into significant economic benefits: municipalities report average lifecycle cost reductions of $88,000 per well over 30 years compared to alternatives. Additionally, precise slot control reduces development time by 3-5 days per installation, representing an 18% reduction in rig time expenses. These screens deliver quantifiable reliability that becomes increasingly vital as water scarcity intensifies globally.

(johnson well screens)

FAQS on johnson well screens

Q: What makes Johnson Well Screens different from other well screen suppliers?

A: Johnson Well Screens specialize in precision-engineered wedge wire screens, offering superior durability and custom designs for diverse applications. Their products are optimized for filtration efficiency and corrosion resistance.

Q: What industries commonly use Johnson Well Screens & Wedge Wire Screens?

A: These screens are widely used in water wells, agriculture, mining, and environmental projects. They excel in applications requiring high flow rates and sediment control.

Q: How do I choose the right well screen supplier for my project?

A: Prioritize suppliers like Johnson Well Screens with proven expertise, material certifications, and custom solutions. Ensure they offer technical support and comply with industry standards.

Q: What materials are Johnson Well Screens typically made from?

A: They are commonly constructed from stainless steel, carbon steel, or corrosion-resistant alloys. Material selection depends on water chemistry, temperature, and environmental conditions.

Q: Can Johnson Well Screens handle high-pressure or abrasive environments?

A: Yes, their wedge wire design and robust construction withstand extreme pressures and abrasive materials. Custom slot sizes further enhance performance in challenging conditions.