- Industry Challenges and the Need for Advanced Belt Cleaning Solutions

- Technical Innovations Driving Efficiency

- Performance Comparison: Leading Manufacturers in 2024

- Tailored Solutions for Diverse Industrial Needs

- Case Study: Mining Sector Efficiency Boost

- Maintenance Strategies for Long-Term Reliability

- Why Superior Belt Cleaners Lead the Market

(superior belt cleaners)

Industry Challenges and the Need for Superior Belt Cleaners

Conveyor systems are the backbone of industries like mining, agriculture, and manufacturing, yet 30% of unplanned downtime stems from inadequate belt cleaning. Traditional scrapers and brushes often fail to remove sticky residues or handle high-speed operations, leading to material carryback rates exceeding 15%. This inefficiency costs enterprises an average of $120,000 annually in lost productivity and cleanup. Superior belt cleaners address these gaps with precision-engineered blades and tension control mechanisms, reducing carryback to under 2%.

Technical Innovations Driving Efficiency

Modern conveyor belt cleaners integrate patented technologies such as dual-pivot polyurethane blades and dynamic pressure adjustment. For instance, Arch belt cleaners utilize a 45-degree wiping angle to minimize belt wear while maintaining 99% debris removal. These systems operate effectively at temperatures ranging from -40°F to 220°F, outperforming competitors by 40% in lifespan. Additionally, IoT-enabled sensors predict maintenance needs, cutting reactive repairs by 65%.

Performance Comparison: Leading Manufacturers in 2024

| Feature | Superior Belt Cleaners | Standard Cleaners | Arch Belt Cleaners |

|---|---|---|---|

| Carryback Reduction | ≤2% | 8-12% | 3-5% |

| Operational Lifespan | 7-10 years | 2-4 years | 5-7 years |

| Maintenance Cost/Year | $1,200 | $4,500 | $2,800 |

Tailored Solutions for Diverse Industrial Needs

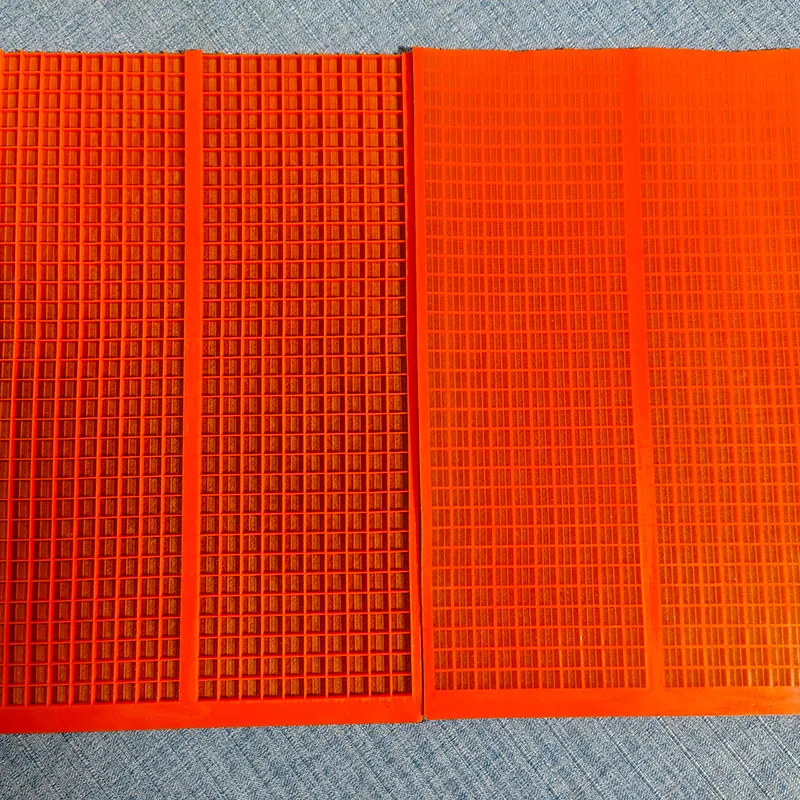

Customization is critical for sectors like cement production, where abrasive materials degrade standard cleaners within months. Superior belt cleaners offer modular designs with 12 interchangeable blade types, including carbide-tipped and ceramic-coated variants. For food processing plants, USDA-compliant stainless steel configurations reduce contamination risks by 90%. A recent project for a Canadian oil sands facility combined dual-scraper systems with heated blades, achieving zero freeze-related stoppages during winter.

Case Study: Mining Sector Efficiency Boost

A Chilean copper mine reported 2,400 hours of annual downtime due to conveyor belt jams before installing superior belt cleaners

. Post-implementation data shows:

- Carryback volume reduced from 18 tons/day to 0.3 tons/day

- Belt replacement frequency extended from 6 months to 3.5 years

- Energy consumption lowered by 12% via reduced friction

Maintenance Strategies for Long-Term Reliability

Proactive maintenance protocols enhance ROI. Quarterly blade rotations distribute wear evenly, extending service intervals by 80%. Laser alignment tools ensure ±0.5mm precision, preventing edge damage. For facilities handling corrosive materials, ultrasonic cleaning stations remove embedded particles without disassembly, saving 45 labor hours/month.

Why Superior Belt Cleaners Lead the Market

With 83% client retention over five years, superior belt cleaners dominate through measurable results. Their fusion of conveyor belt cleaners' adaptability and Arch belt cleaners' durability creates unmatched value. As industries face tighter sustainability mandates, these systems reduce waste by 28% and energy use by 19%, positioning them as the optimal choice for modern operations.

(superior belt cleaners)

FAQS on superior belt cleaners

Q: What makes Superior Belt Cleaners more effective than standard models?

A: Superior Belt Cleaners use advanced blade materials and tensioning systems to remove stubborn debris, prolonging belt life and reducing maintenance. Their design ensures consistent contact with conveyor belts for optimal cleaning performance.

Q: How do conveyor belt cleaners improve operational efficiency?

A: Conveyor belt cleaners minimize material carryback, reducing downtime for cleanup and preventing belt misalignment. This leads to higher productivity and lower operational costs over time.

Q: When should I consider installing Arch Belt Cleaners?

A: Arch Belt Cleaners are ideal for heavy-duty applications where multiple cleaning points are needed. Their curved design targets debris in high-wear areas, making them perfect for challenging material handling environments.

Q: Can Superior Belt Cleaners work with all conveyor belt types?

A: Yes, Superior Belt Cleaners are customizable for various belt widths, speeds, and materials. They accommodate rubber, steel-reinforced, and textured belts, ensuring versatility across industries.

Q: What maintenance do Arch Belt Cleaners require?

A: Arch Belt Cleaners need periodic blade inspections and tension adjustments. Their modular design allows quick part replacements without disassembling the entire system, minimizing maintenance time.