Below is a comprehensive overview of industrial filtration solutions:

- Fundamentals of continuous slot technology

- Performance metrics and filtration efficiency data

- Material science behind corrosion resistance

- Comparative manufacturer analysis table

- Customization parameters for industrial applications

- Cross-industry implementation case studies

- Innovations in separation technology

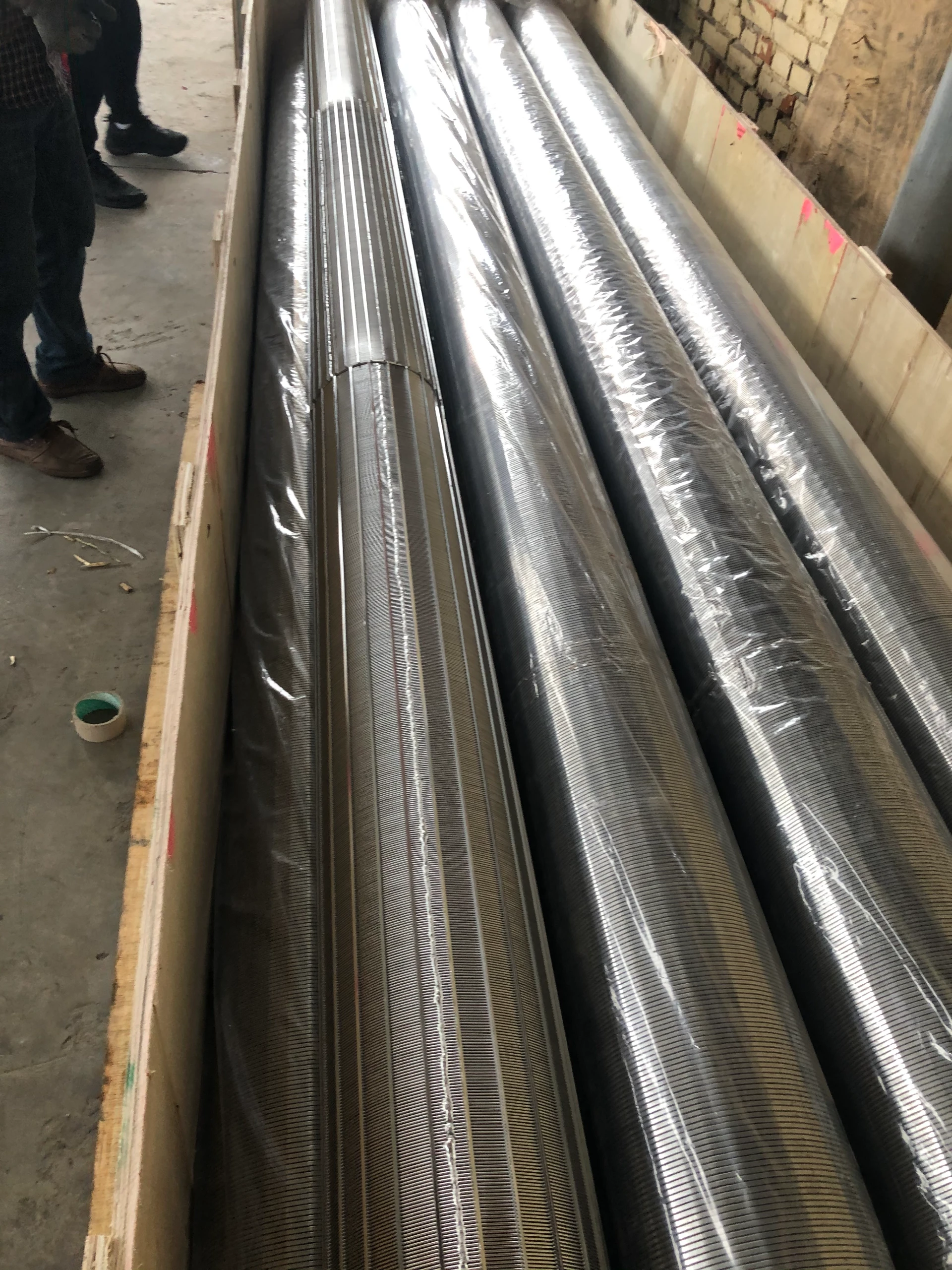

(vee wire screen)

Understanding Vee Wire Screen Technology Fundamentals

Wedge wire construction represents the engineering pinnacle of continuous slot filtration. Unlike punched plates or mesh alternatives, vee wire filter screens feature precision-welded triangular profile wires arranged over support structures with uniform slot openings ranging from 0.020mm to 25mm. This architecture delivers consistent filtration accuracy while maintaining exceptional structural integrity under pressures exceeding 1000 PSI. The inherent non-blinding design prevents particle accumulation through continuous flow paths, critical for processing viscous media like petrochemical slurries or wastewater biosolids where traditional screens fail within 600 operational hours.

Material Science Behind Industrial Durability

Material selection dictates performance longevity in filtration systems. Premium wedge wire screens utilize 316/L stainless steel as standard, providing chloride resistance up to 500 ppm at 60°C. For extreme environments like mining tailing ponds with pH levels below 2.5, super duplex variants offer 3x the corrosion resistance of standard alloys while maintaining 65 HRC hardness. Surface treatments like passivation reduce particulate adhesion by 70% compared to untreated surfaces, validated through ASTM A967 testing. Post-weld heat treatment stabilizes molecular structures against thermal cycling stress, extending service life beyond industry-average 10-year benchmarks in desalination plants.

Industrial Filtration Solution Providers

| Manufacturer | Tolerance Control | Material Range | Max Temp (°C) | Delivery Lead Time |

|---|---|---|---|---|

| Standard Solutions Ltd | ±0.05mm | Carbon steel, SS304/316 | 400 | 8 weeks |

| Precision Screens Inc | ±0.01mm | Hastelloy, Monel, Alloy 20 | 650 | 5 weeks |

| Advanced Filtration Co | ±0.005mm | Super duplex, Titanium | 800 | 3 weeks |

Leading suppliers differentiate through fabrication capabilities—Precision Screens Inc holds patents for laser-welded joints increasing burst pressure resistance by 45% versus conventional methods. Advanced Filtration Co's ISO 9001:2015 certified facilities enable multi-axis wire profiling for complex geometries required in pharmaceutical separation towers.

Configuration Parameters for Precision Applications

Customization begins with slot geometry optimization. Fish processing plants utilize 0.5mm slots with trapezoidal wires eliminating fouling during protein separation. Petrochemical applications specify 316L steel with 0.10mm slot tolerances ±0.003mm for catalyst recovery. Dimensional versatility includes cylindrical designs up to 3m diameter for LNG scrubbers or planar variants for mining shaker screens. Support ring configurations vary from 10cm spacing for coarse coal separation to 2.5cm layouts for phosphoric acid clarification at 60,000 liters/hour flow rates. Surface modifications like electropolishing achieve Ra≤0.8μm smoothness for CIP-compliant food processing.

Cross-Industry Implementation Case Studies

Water reclamation plants in California's Orange County achieved 98% filter efficiency using 0.15mm vee wire screen

s, reducing backflush cycles from every 72 to 120 hours. Oil sands operations in Alberta reported 32% throughput increase after replacing mesh screens with 2mm wedge wire filter panels capable of handling 7,000 cP viscosity fluids at 85°C. Food manufacturers eliminated product contamination incidents by implementing laser-welded wedge wire screens meeting FDA 21 CFR compliance, validated through microbial adhesion reduction tests.

Evolution in Separation Technologies

Current research focuses on surface-engineered alloys with hydrophobic properties reducing particulate adhesion by 65% in trials. Digital twin integration allows predictive maintenance through IoT-enabled pressure sensors mapping clogging patterns across filter surfaces. Additive manufacturing breakthroughs permit complex wire geometries previously unachievable through conventional fabrication, including gradient slot designs that self-adjust flow characteristics. Nano-coating applications demonstrate promise in extending operational intervals for desalination pre-filters by 40% between cleaning cycles.

Optimizing Operations with Advanced Vee Wire Screens

Proper specification requires technical alignment between operational parameters and screen characteristics. Process engineers must consider slot dimensions relative to particle distribution curves—optimal slot width equals D90 particle size ÷ 1.5. Flow velocities should be maintained between 0.3-1.2 m/s to balance throughput and self-cleaning action. Regular integrity testing per ASME BPE standards verifies slot consistency through air pressure decay methods. Proactive maintenance protocols include ultrasonic cleaning every 1,500 operational hours for mineral processing applications. These strategies ensure welded wedge wire screens deliver maximum ROI through 8-12 year service lifecycles in continuous filtration systems.

(vee wire screen)

FAQS on vee wire screen

Here are 5 English FAQ pairs presented in HTML format with h3 tags and concise answers:Q: What is a vee wire screen?

A: A vee wire screen features triangular-profile wires welded onto support rods. This creates precise slot openings for accurate particle separation. Its wedge-shaped wires prevent clogging during filtration.

Q: Where are vee wire filter screens commonly used?

A: They're essential in water treatment plants for sand removal. Industries like mining and food processing use them for sizing materials. Oil refineries also deploy them in separator vessels.

Q: Why choose welded wedge wire screen over perforated plates?

A: Welded construction provides superior strength and slot uniformity. The V-shaped wires enable self-cleaning properties during operation. They offer higher flow rates with minimal pressure drop compared to plates.

Q: How are vee wire screen slot sizes determined?

A: Slot dimensions are controlled by calibrating wire spacing during welding. Available ranges typically span 20 microns to 25mm. Custom openings can be produced for specific particle separation needs.

Q: Can welded wedge wire screens handle high temperatures?

A: Yes, stainless steel constructions withstand temperatures up to 800°F (427°C). Alloy variants support even more extreme thermal conditions. The welded junctions maintain structural integrity under thermal cycling.